Material processing system based on multi-axis robot, and processing method thereof

A multi-axis robot and processing system technology, applied in stone processing tools, metal processing, stone processing equipment and other directions, can solve the problems of increasing space, the guide rail structure cannot be contracted and adjusted, etc., to improve efficiency, improve material processing efficiency, The effect of saving placement space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

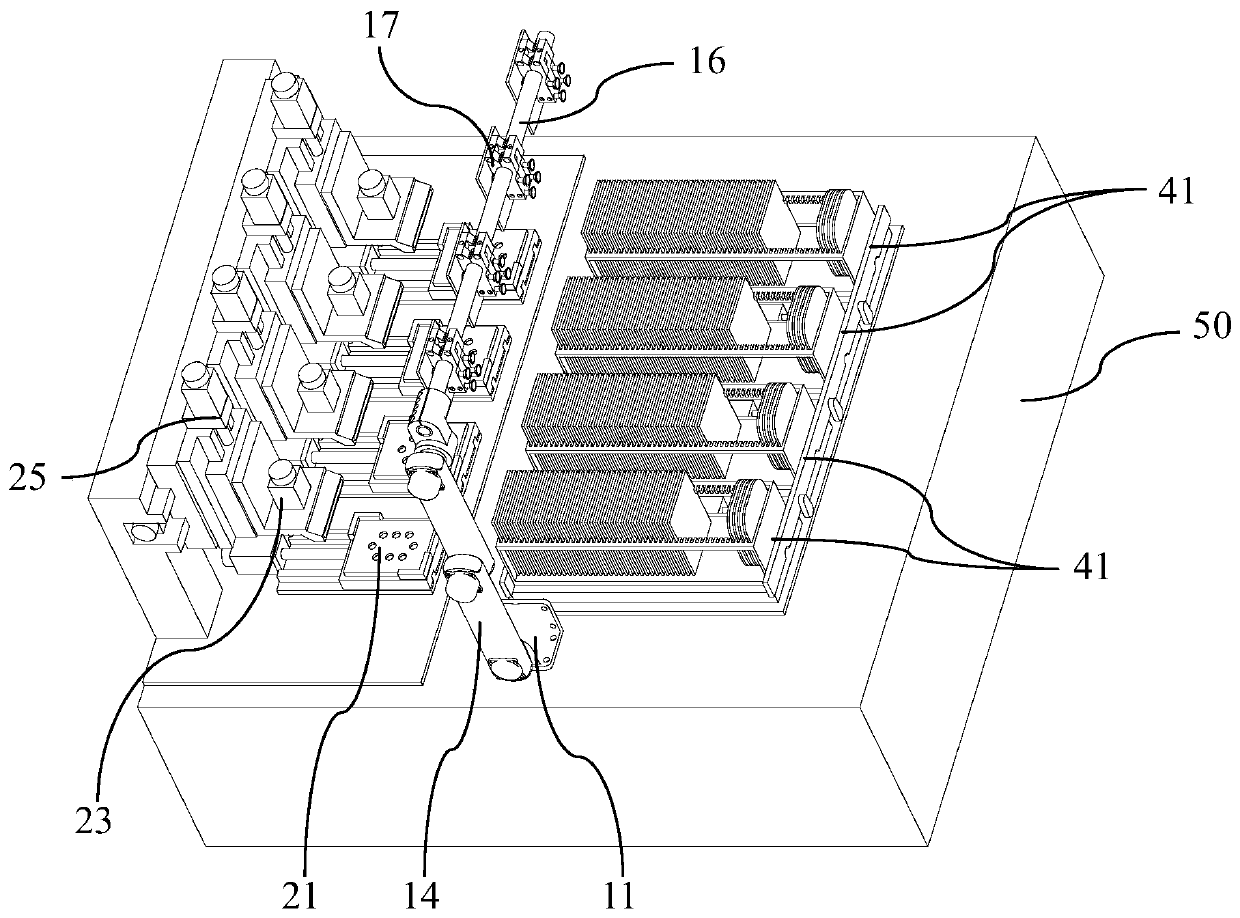

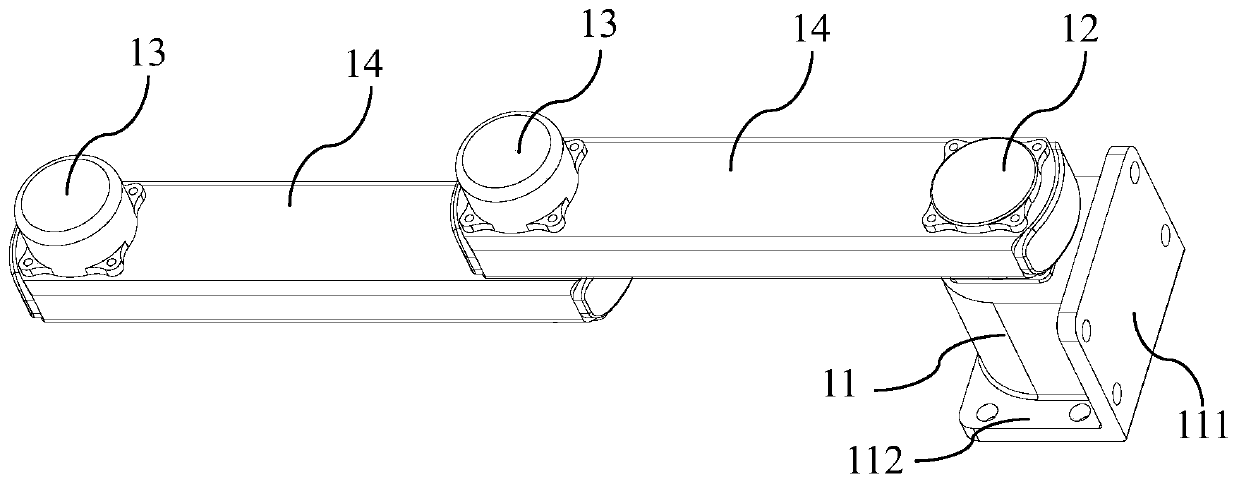

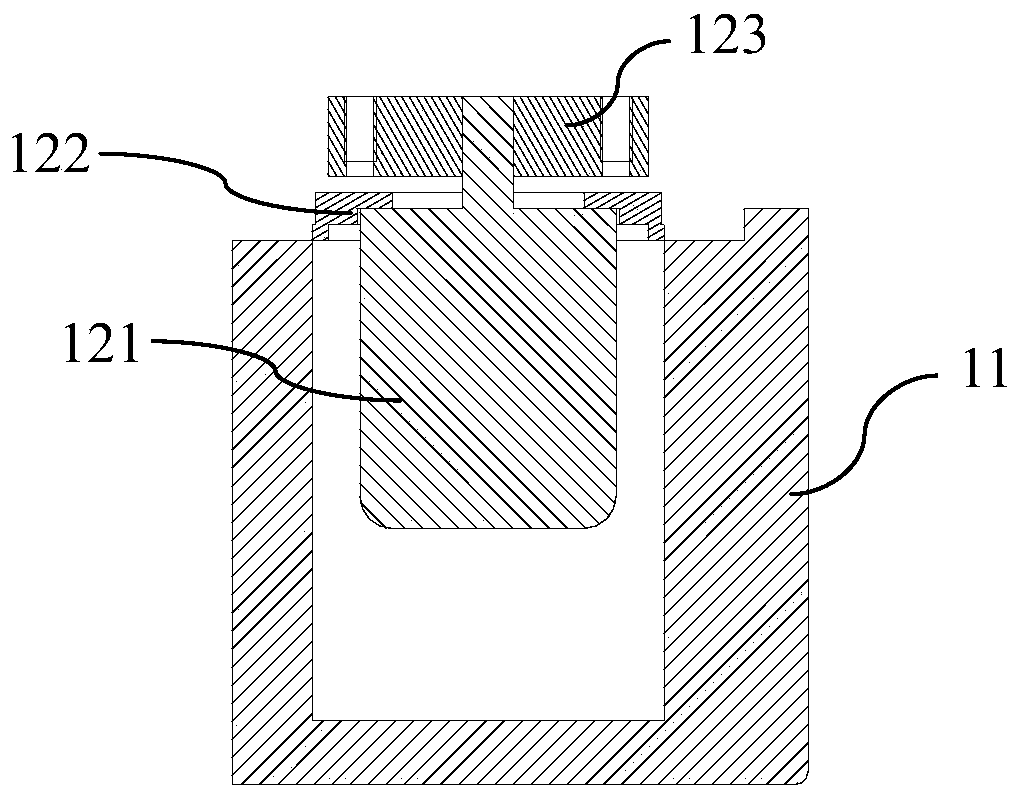

[0059] Such as figure 1 As shown, it is a structural schematic diagram of a material processing system based on a multi-axis robot provided by an embodiment of the present invention. The material processing system can be applied to automatic production and realize material pick-and-place. The material processing system based on the multi-axis robot of the present embodiment includes a loading and unloading device, a processing device and a chute, wherein the chute is used to place materials to be processed and processed materials, and the processing device includes a processing station 21, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap