Microwave ferrite magnetic sheet, preparation method and applications thereof

A ferrite magnetic and microwave technology, applied in the field of ferrite, can solve the problems of meeting the size requirements of 5G base station circulators/isolators, and achieve the effects of reducing line width, reducing insertion loss, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment prepares microwave ferrite magnetic sheet according to the following method:

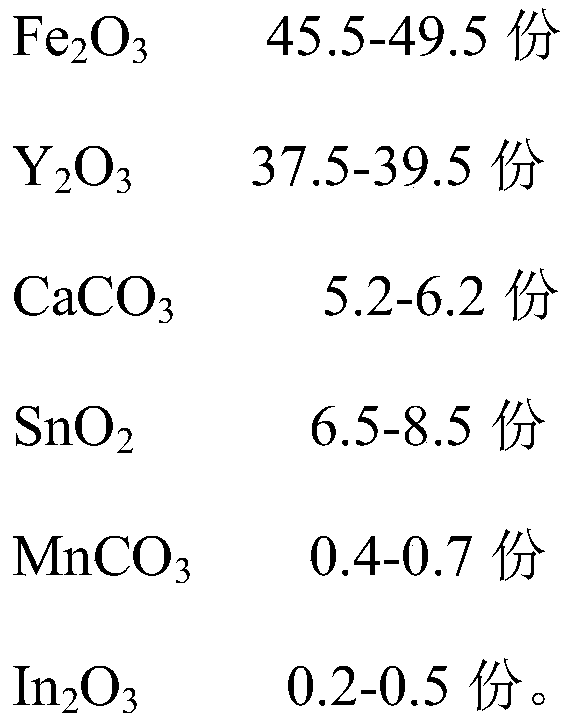

[0073] 1. Weigh the raw materials according to the following weight ratio:

[0074]

[0075] 2. One ball mill

[0076] Mix the raw materials weighed in 1 into a stainless steel ball mill tank, add steel balls and deionized water according to the ratio of material: ball: water = 1:4.5:0.9 to carry out a wet ball mill, time: 18 hours.

[0077] 3. Drying

[0078] Pass the ball-milled material through a 100-mesh sieve, and dry it at 150°C for 15 hours to obtain a dry material.

[0079] 4. Pre-sintering

[0080] Pass the dried powder through a 30-mesh sieve, put it in a bowl and put it into a high-temperature electric furnace for pre-burning at a temperature of 1200°C and keep it warm for 10 hours.

[0081] 5. Second ball milling

[0082] The mixture after pre-burning is crushed, put into a stainless steel ball mill tank, and steel balls and deionized water are added accord...

Embodiment 2

[0101] This embodiment prepares microwave ferrite magnetic sheet according to the following method:

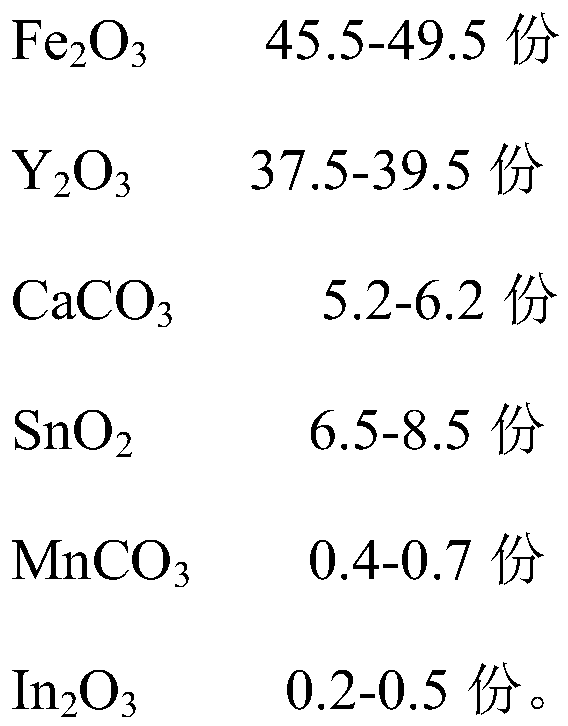

[0102] 1. Weigh the raw materials according to the following weight ratio:

[0103]

[0104] 2. One ball mill

[0105] Mix the raw materials weighed in 1 into a stainless steel ball mill tank, add steel balls and deionized water according to the ratio of material: ball: water = 1:4.5:0.9 to carry out a wet ball mill, time: 18 hours.

[0106] 3. Drying

[0107] Pass the ball-milled material through a 100-mesh sieve, and dry it at 150°C for 15 hours to obtain a dry material.

[0108] 4. Pre-sintering

[0109] Pass the dried powder through a 30-mesh sieve, put it in a bowl and put it into a high-temperature electric furnace for pre-burning at a temperature of 1200°C and keep it warm for 10 hours.

[0110] 5. Second ball milling

[0111] The mixture after pre-burning is crushed, put into a stainless steel ball mill tank, and steel balls and deionized water are added accord...

Embodiment 3

[0130] This embodiment prepares microwave ferrite magnetic sheet according to the following method:

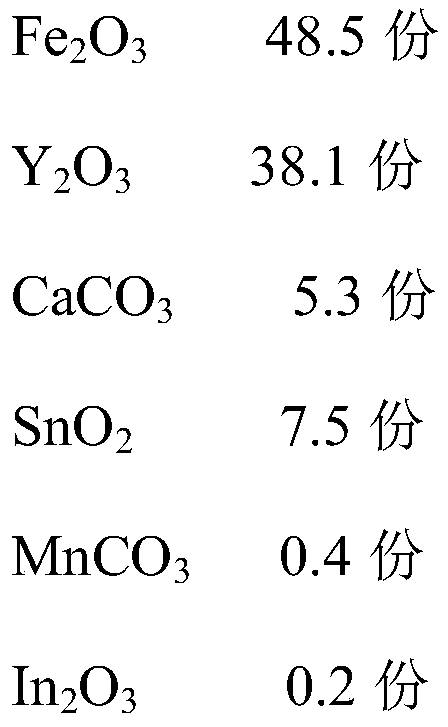

[0131] 1. Weigh the raw materials according to the following weight ratio:

[0132]

[0133]

[0134] 2. One ball mill

[0135] Mix the raw materials weighed in 1 into a stainless steel ball mill tank, add steel balls and deionized water according to the ratio of material: ball: water = 1:4.5:0.9 to carry out a wet ball mill, time: 18 hours.

[0136] 3. Drying

[0137] Pass the ball-milled material through a 100-mesh sieve, and dry it at 150°C for 15 hours to obtain a dry material.

[0138] 4. Pre-sintering

[0139] Pass the dried powder through a 30-mesh sieve, put it in a bowl and put it into a high-temperature electric furnace for pre-burning at a temperature of 1200°C and keep it warm for 10 hours.

[0140] 5. Second ball milling

[0141] The mixture after pre-burning is crushed, put into a stainless steel ball mill tank, and steel balls and deionized water are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com