Method for preparing nicotine

A nicotine and acid solution technology, applied in organic chemistry methods, organic chemistry and other directions, can solve the problems of low efficiency, difficult industrial production, low purity of S-nicotine, etc., and achieve the effect of high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

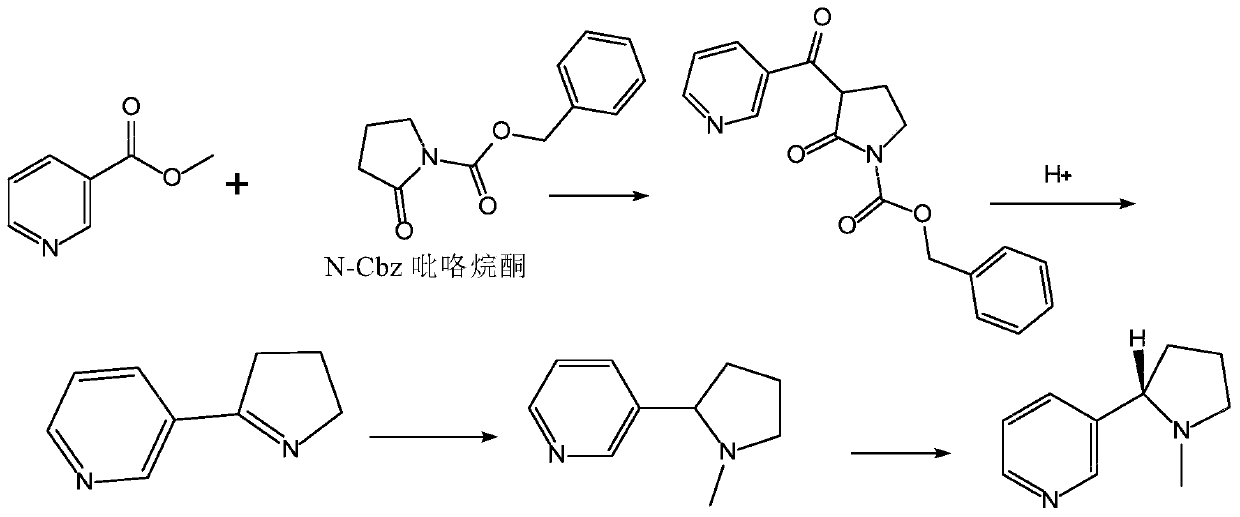

[0061] Synthesis of racemic nicotine

[0062] In a 10L reactor, 1.58kg (14mol 1.5eq) of potassium tert-butoxide, 1.85kg (8.43mol 0.9eq) of N-Cbz pyrrolidone, and 7.5L of tetrahydrofuran were successively put in, stirred for 15 minutes, and 1.29kg of methyl nicotinate ( 7.5 L of tetrahydrofuran solution (9.38 mol) was added dropwise into the reactor, and after the dropwise addition, the temperature was raised to 66° C. for reflux reaction, and the reaction time was 12 hours.

[0063] After the reaction was completed, it was lowered to room temperature, and then at room temperature, formic acid was added dropwise to neutralize the system until the pH of the system was 7, and tetrahydrofuran was recovered by rotary evaporation under reduced pressure to dryness to obtain the first solid mixture.

[0064] Subsequently, 5 L of 6M hydrochloric acid solution was added, the temperature was raised to 100° C., and a reflux reaction was carried out under stirring. The reaction time was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com