Large tidal range deepwater causeway closure gap closure steel frame cage structure and closure gap closure construction method thereof

A large tidal range and steel frame technology, applied in the direction of dikes, dams, jetties, etc., can solve the problems of easily damaged dike heads on both sides of the Longkou and poor positioning effect of the intercepting dam, so as to improve construction safety, good positioning effect, reduce The effect of scour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

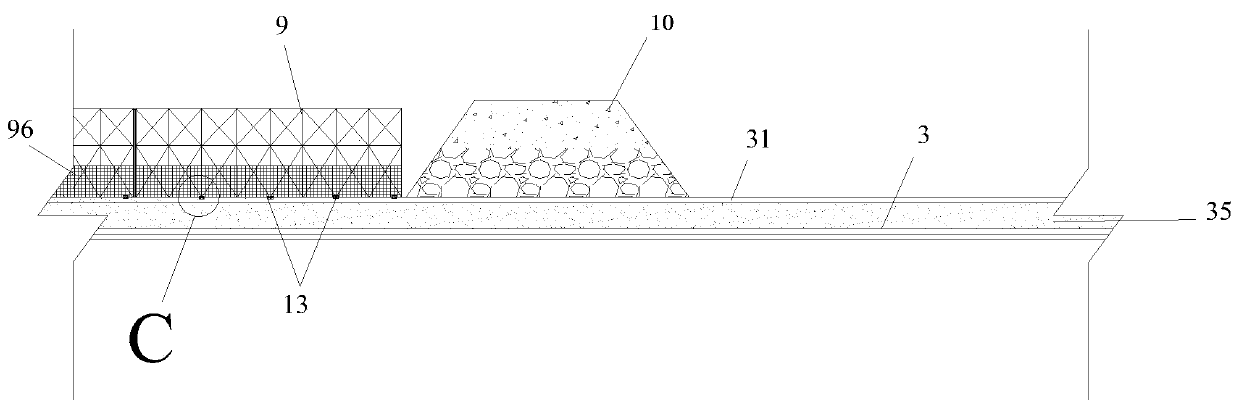

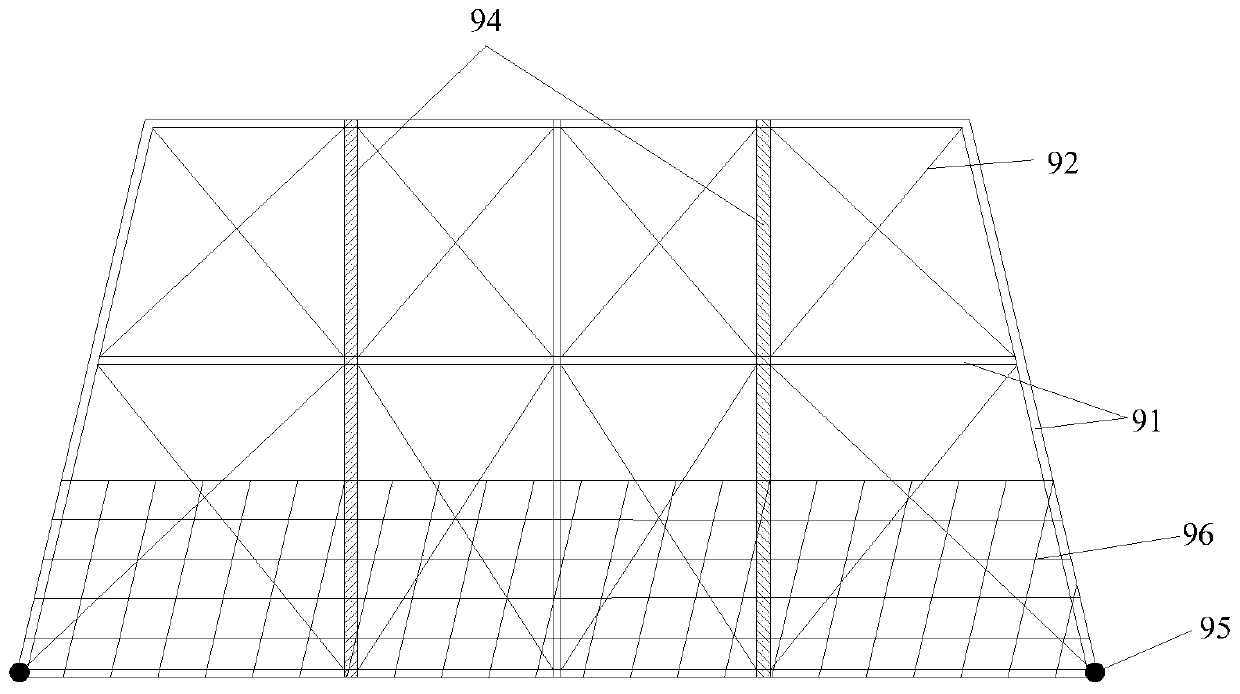

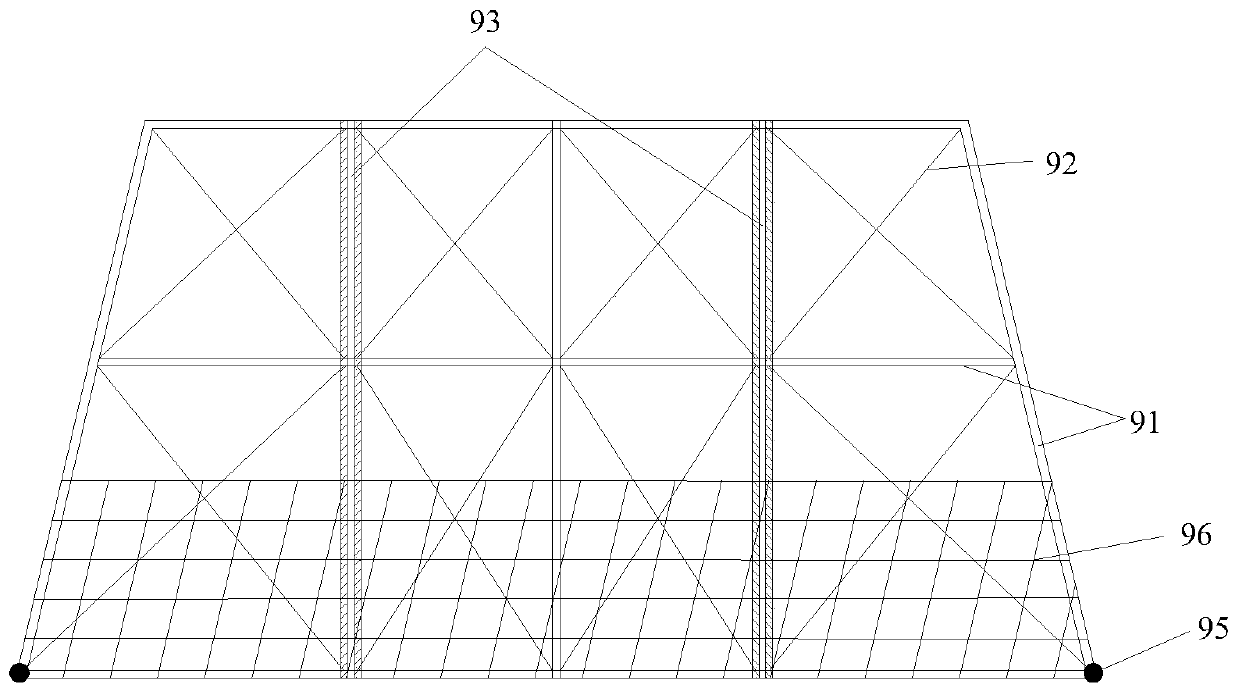

[0060] combined with Figure 1~3 As shown, in this embodiment, the steel frame cage 9 is a prism body, and the section parallel to the dragon mouth is a rectangle obliquely intersecting with the bottom surface of the river bed. A fixed steel pipe 95 with a diameter of 5 to 10 cm is arranged on the outer sides of the two profiled steel skeletons 1 in contact with the soft row body 3 on both sides, and steel mesh 96 with small spacing is arranged on both sides of the steel frame cage 9 parallel to the dragon mouth; the steel mesh 96 is arranged on The bottom of the steel frame cage 9, the setting range is from the bottom of the steel frame cage 9 to 1 / 3 of the height of the steel frame cage 9; the vertical dragon mouth section is an isosceles trapezoid perpendicular to the riverbed ground, and the cross-sectional size (upper bottom × lower bottom × height) is 8 × 12m × 6.5m; the two sides of the steel frame cage 9 perpendicular to the dragon mouth are provided with steel mesh 96...

Embodiment 2

[0064] A construction method for the closure of a steel frame cage structure with a large tidal range and deep water embankment with a closure at the mouth of the mouth of the embankment, combined with the attached Figure 20 , adopt the following construction steps:

[0065] S1, combined with attached Figure 4 , attached Figure 5 , attached Figure 15 As shown, the lock catch 13 is prefabricated and placed: the lock catch 13 device is prefabricated in the factory, and is installed on the concrete interlocking sheet 11 of the designated interlock row 34 by bolts 15, nuts 14 and gaskets 16;

[0066] S2, combined with attached Image 6 ~ attached Figure 9 As shown, preliminary preparations: carry out embankment foundation treatment, insert and drill drainage boards, and carry out the construction of the bottom protection of the dragon mouth. The bottom protection of the dragon mouth in the length direction is a three-stage structure, and the left and right sides are prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com