Novel conduction oil low-temperature expansion tank

A technology of expansion tank and heat transfer oil, which is used in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of inconvenient cleaning and slow cooling speed of expansion tanks, and achieve convenient and thorough cleaning and simple structure. novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

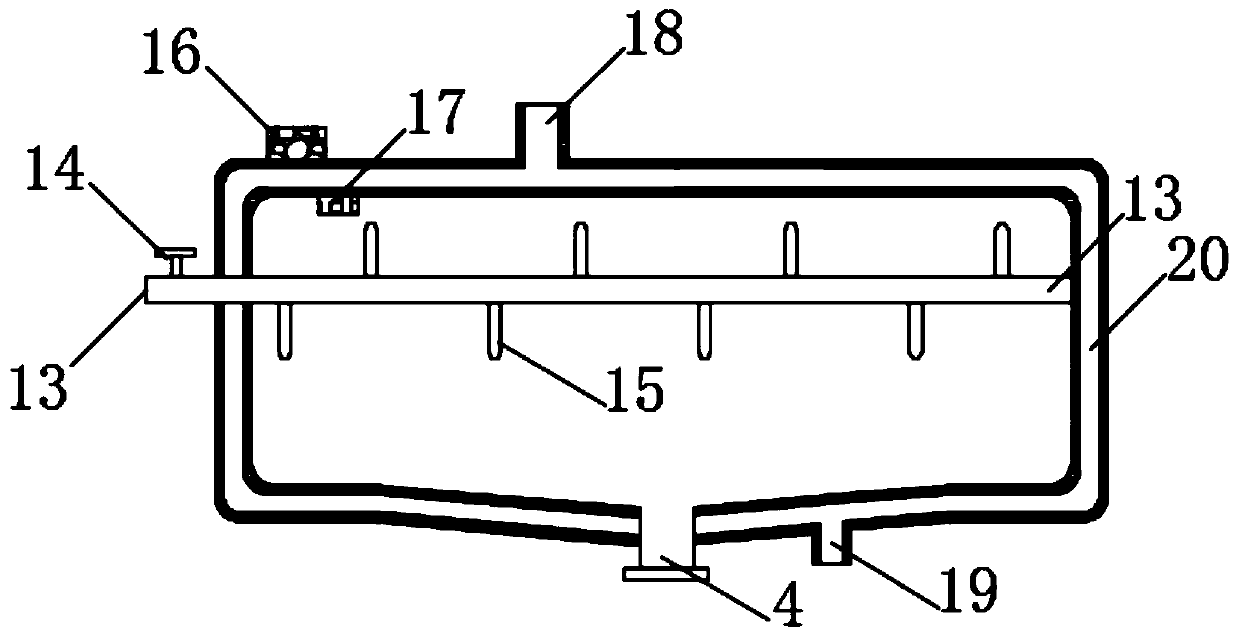

[0017] Such as Figure 1-2 As shown, the present invention provides a new low-temperature expansion tank for heat-conducting oil, which includes an expansion tank body 1. The expansion tank body 1 is provided with an expansion tank 2. Both ends of the bottom of the expansion tank 2 are symmetrically fixedly connected with fixed brackets 3. The bottom of the expansion tank 2 The middle position is fixedly connected with the sewage outlet 4, one end of the bottom of the expansion tank 2 is fixedly connected with the water outlet 19 and the circulating water pump 6, the water outlet 19 is connected with the circulating water pump 6 through the drain pipe 5, and the expansion tank 2 is close to one end of the circulating water pump 6 A water tank 7 is fixedly connected, the top of the water tank 7 is fixedly connected with a chiller 8, and the top of the expansion tank 2 is fixedly connected with a cooling water pump 10 and a water inlet 18, and the cooling water pump 10 is connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap