Making method of braised young pigeons

A production method, the technology of squab, applied in food coating, the function of food ingredients, food ingredients as a coating agent, etc., can solve the problems of unstable oil pouring process, difficult quality control, etc., and achieve natural red and bright color , sweet taste, mellow taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: a kind of preparation method of braised squab, comprises the steps:

[0023] (1) put the cleaned squab into the pickling preparation and marinate for 4 hours; the formula of the pickling preparation is: the mass percentage is based on the squab mass: 7.5% of salt, 0.4% of star anise, 0.1% of Chinese prickly ash, 0.1% of pepper, 0.5% cinnamon, 0.5% tangerine peel, 0.1% bay leaf, 0.5% fennel, 0.5% licorice, 5% ginger, 1% soy sauce, 20% rice wine;

[0024] (2) Put the marinated squab into the stewed soup and boil for 2 hours, then air-dry for 40 minutes at 45°C in a blast dryer;

[0025] (3) configure crispy skin water, described crispy skin water is made up of following mass percentage:

[0026] Corn flour content: 2.4%, maple syrup content: 2.4%, Timding sweet vinegar content: 1.6%, the rest is 93.6% of the processed Hakka wine, the total amount is 500g; the air-dried squab is evenly coated with crispy skin Water, blow with a hair dryer at low wind for 1m...

Embodiment 2

[0029] Embodiment 2: the impact of different formulations of crispy skin water on the quality of braised squab

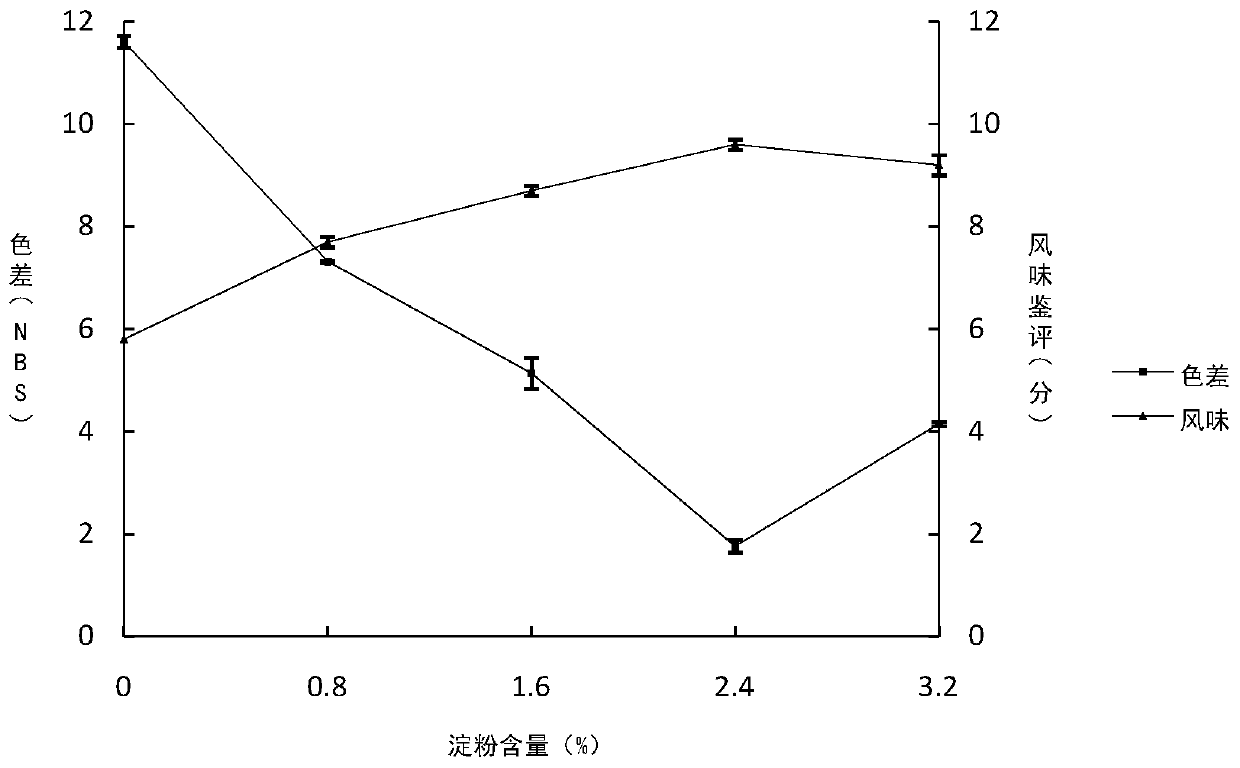

[0030] Use soybean oil, the firing method is oil leaching, the oil leaching temperature is 180°C, and the oil leaching time is 7min. The experiment is carried out according to the method in Example 1, and the results are as follows figure 1 .

[0031] Depend on figure 1 It can be seen that when cornstarch content accounts for 2.4% of the pigeon weight, the color difference of braised squab is the smallest, and the flavor evaluation score is also high. The cornstarch content is in the range of 0-2.4%, and the color difference increases with the cornstarch content. increase and decrease, and after the content of raw corn flour increases to more than 2.4%, the color difference increases instead, so the optimum content of corn flour is 2.4%.

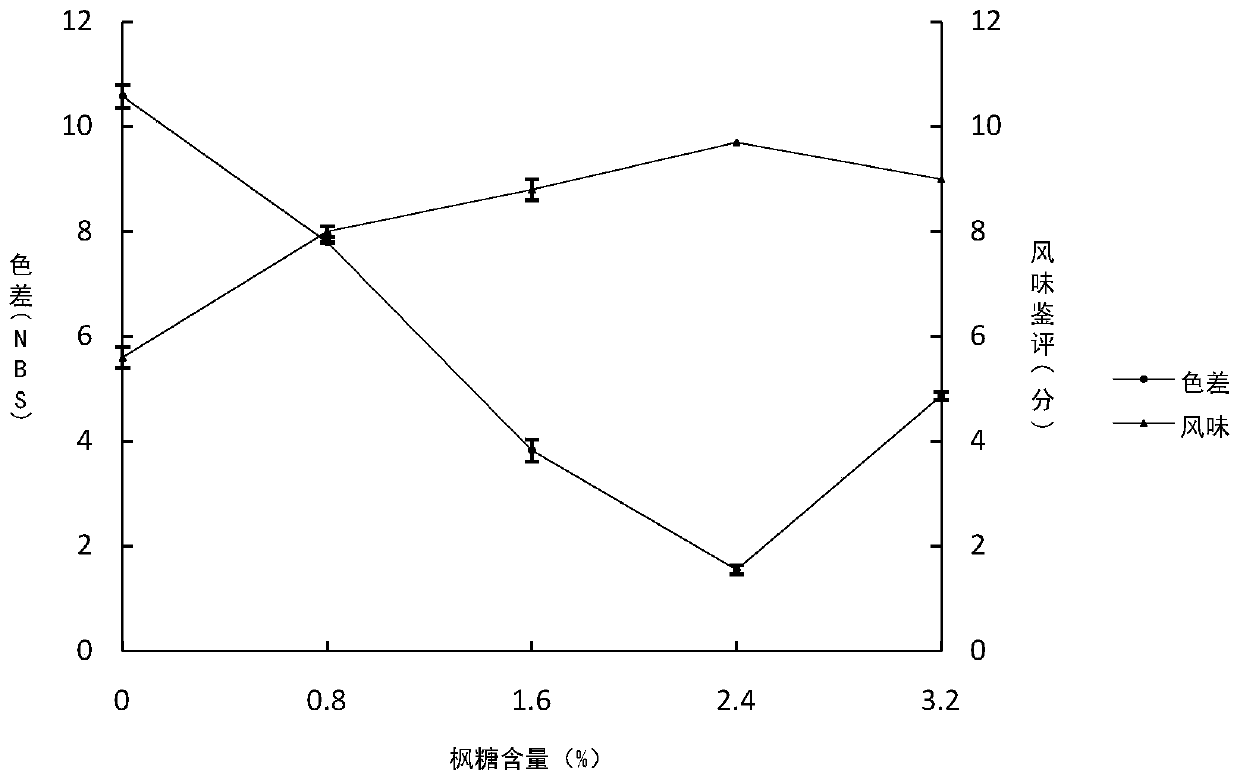

[0032] According to the test results, it is determined to use soybean oil, the firing method is oil leaching, the oil leaching...

Embodiment 3

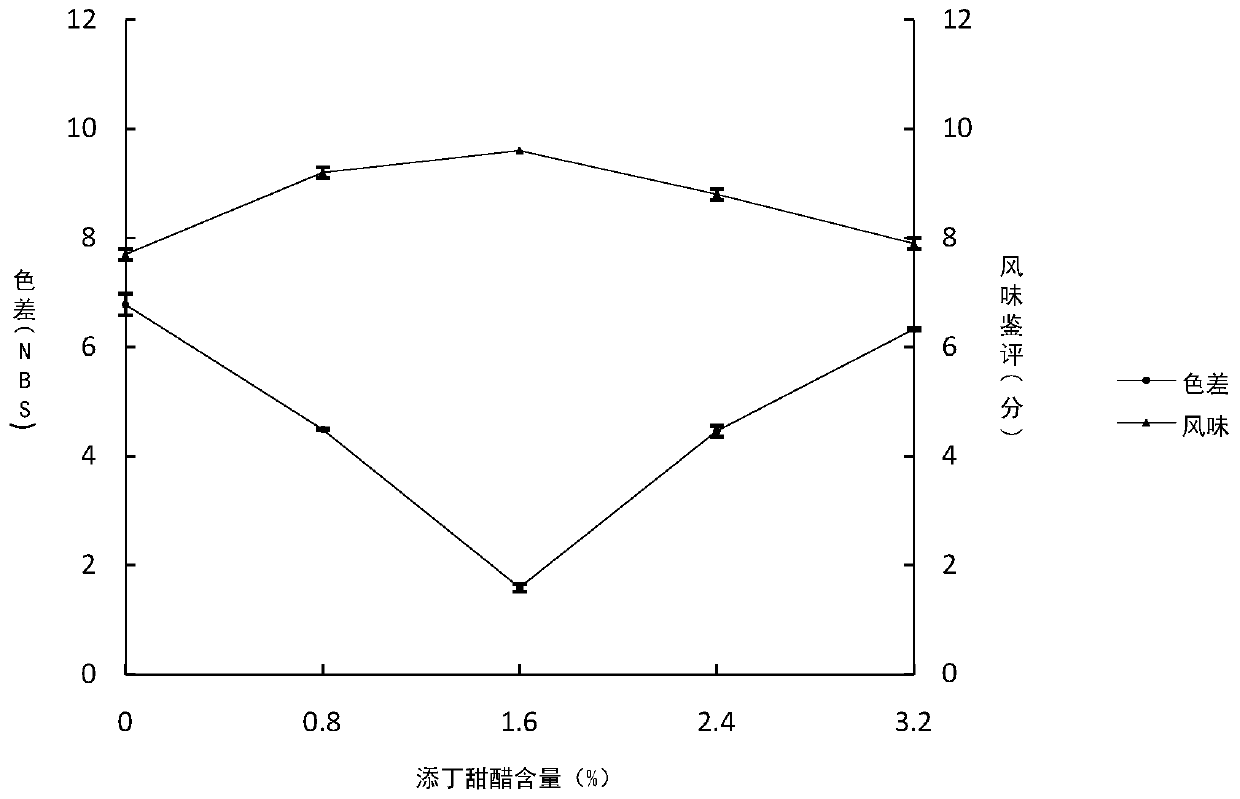

[0033] According to the test results, it is determined to use soybean oil, the firing method is oil leaching, the oil leaching temperature is 180°C, the oil leaching time is 7 minutes, the corn flour content is 2.4%, and the maple sugar content is 2.4%, according to the method in Example 1 experiment, the result is image 3 . Depend on image 3 It can be seen that when the vinegar content accounts for 1.6% of the weight of the pigeon, the color difference of the braised squab is the smallest, and the flavor evaluation score is the highest. The vinegar content is in the range of 0-1.6%, and the color difference decreases with the increase of the vinegar content. After the vinegar content increases above 1.6%, the color difference increases instead, so the optimum vinegar content is 1.6%. Embodiment 3: Determination of crispy skin water component content

[0034] During the oil drench process, the Maillard reaction occurs on the skin of the pigeons that have been dipped in cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com