Preparation method of cerium-based composite oxide low-temperature SCR catalyst taking Ce-MOF as precursor

A technology of SCR catalyst and composite oxide, which is applied in the field of low-temperature SCR catalyst preparation of cerium-based composite oxides, can solve the complicated impregnation process and other problems, and achieve the effect of fast synthesis, simple impregnation process, and outstanding low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

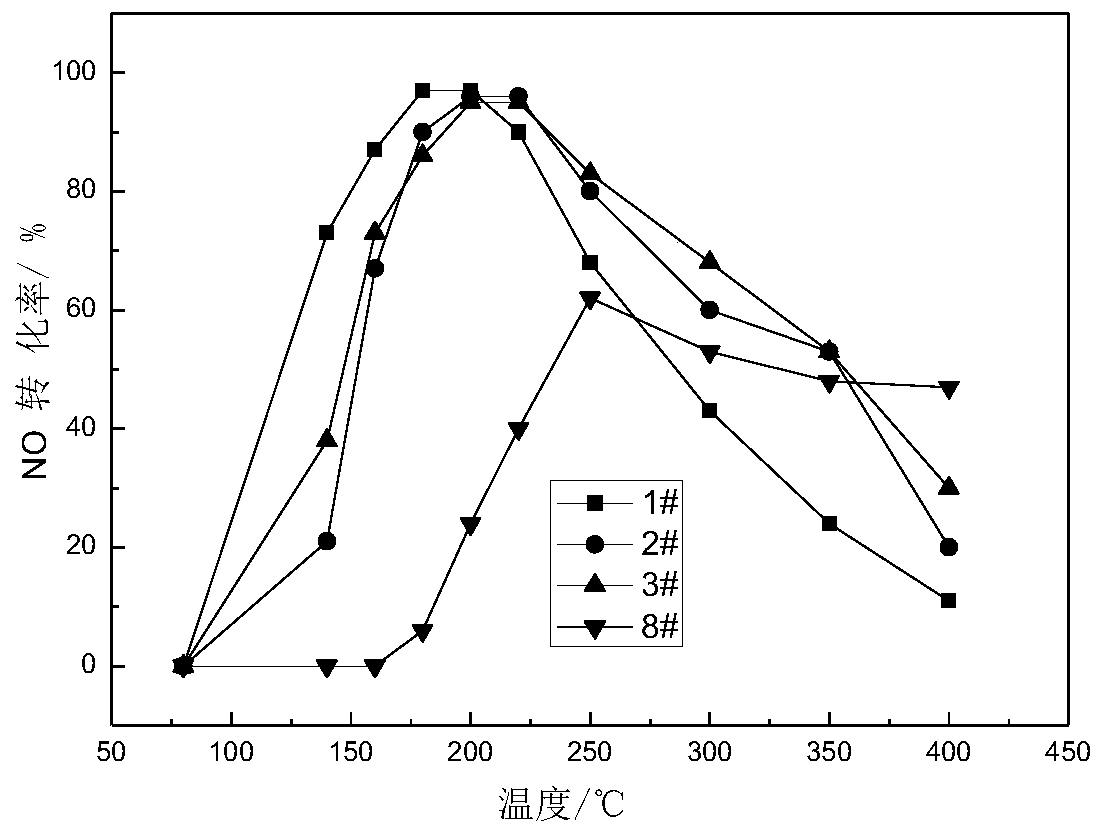

[0027] Weigh 5.20g Cu(NO 3 ) 2 ·3H 2 O in 1000mL ethanol, after stirring and dissolving, add 16g Ce-MOF (equivalent to 6.90g CeO 2 ), placed in an oil bath at 60°C, stirred at 300r / min for 12h, then filtered to remove excess copper nitrate solution, washed with alcohol to remove copper nitrate molecules on the surface, and dried at 100°C to obtain a catalyst precursor. The catalyst precursor was put into a muffle furnace and calcined at 350°C for 5h to obtain 1# sample. The content of CuO in the sample is shown in Attached Table 1, the same below.

Embodiment 2

[0029] Weigh 3.68g Cu(NO 3 ) 2 ·3H 2 O in 1000mL ethanol, after stirring and dissolving, add 16g Ce-MOF (equivalent to 6.90g CeO 2 ), placed in an oil bath at 60°C, stirred at 300r / min for 12h, then filtered to remove excess copper nitrate solution, washed with alcohol to remove copper nitrate molecules on the surface, and dried at 100°C to obtain a catalyst precursor. The catalyst precursor was put into a muffle furnace and calcined at 350°C for 5h to obtain 2# sample.

Embodiment 3

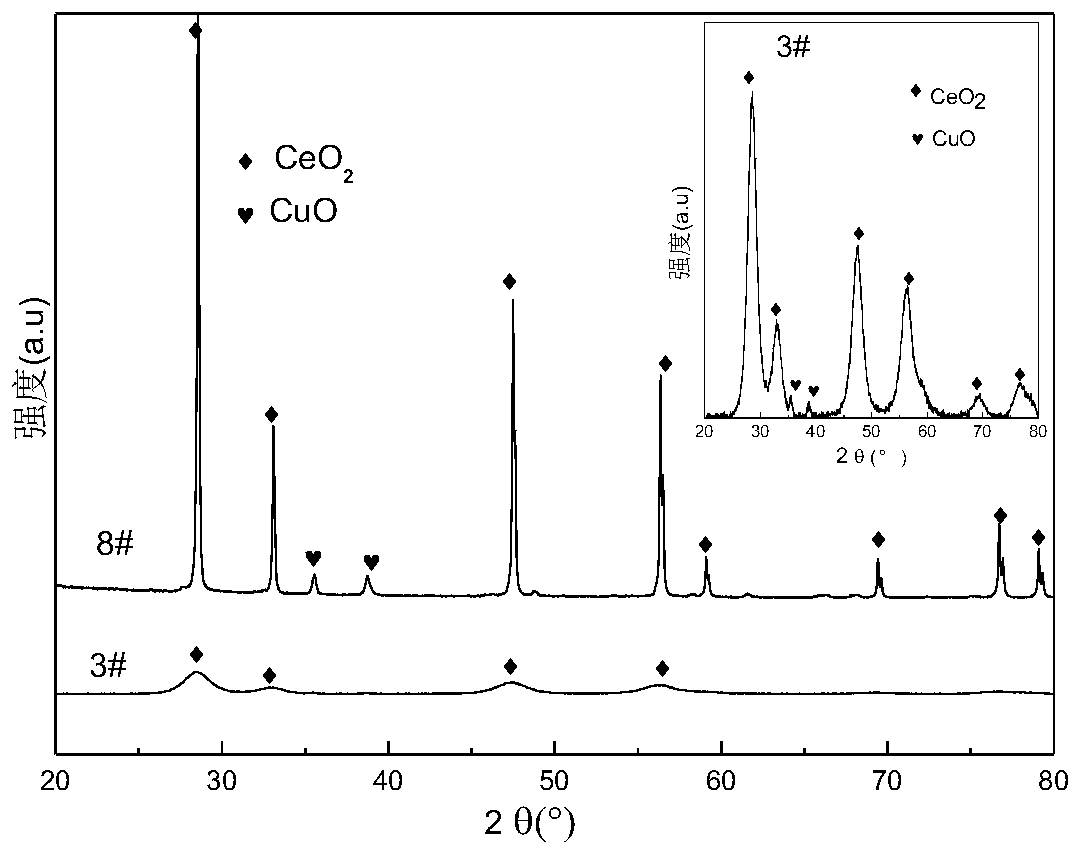

[0031] Weigh 2.33g Cu(NO 3 ) 2 ·3H 2 O in 1000mL ethanol, after stirring and dissolving, add 16g Ce-MOF (equivalent to 6.90g CeO 2 ), placed in an oil bath at 60°C, stirred at 300r / min for 12h, then filtered to remove excess copper nitrate solution, washed with alcohol to remove copper nitrate molecules on the surface, and dried at 100°C to obtain a catalyst precursor. The catalyst precursor was put into a muffle furnace and calcined at 350°C for 5h to obtain 3# sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com