Tree-shaped special swing welding method

A welding method and special technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as poor welding, and achieve the effect of reducing undercut and increasing welding penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The present invention provides a tree-shaped special swing welding method. When gas-shielded arc welding is performed, the measurement position formed by the base metal and the base metal overlaps the solid lining material on the inner side. The specific operation method is as follows:

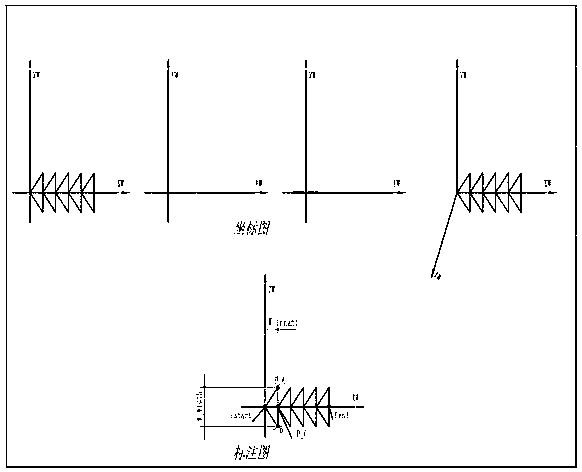

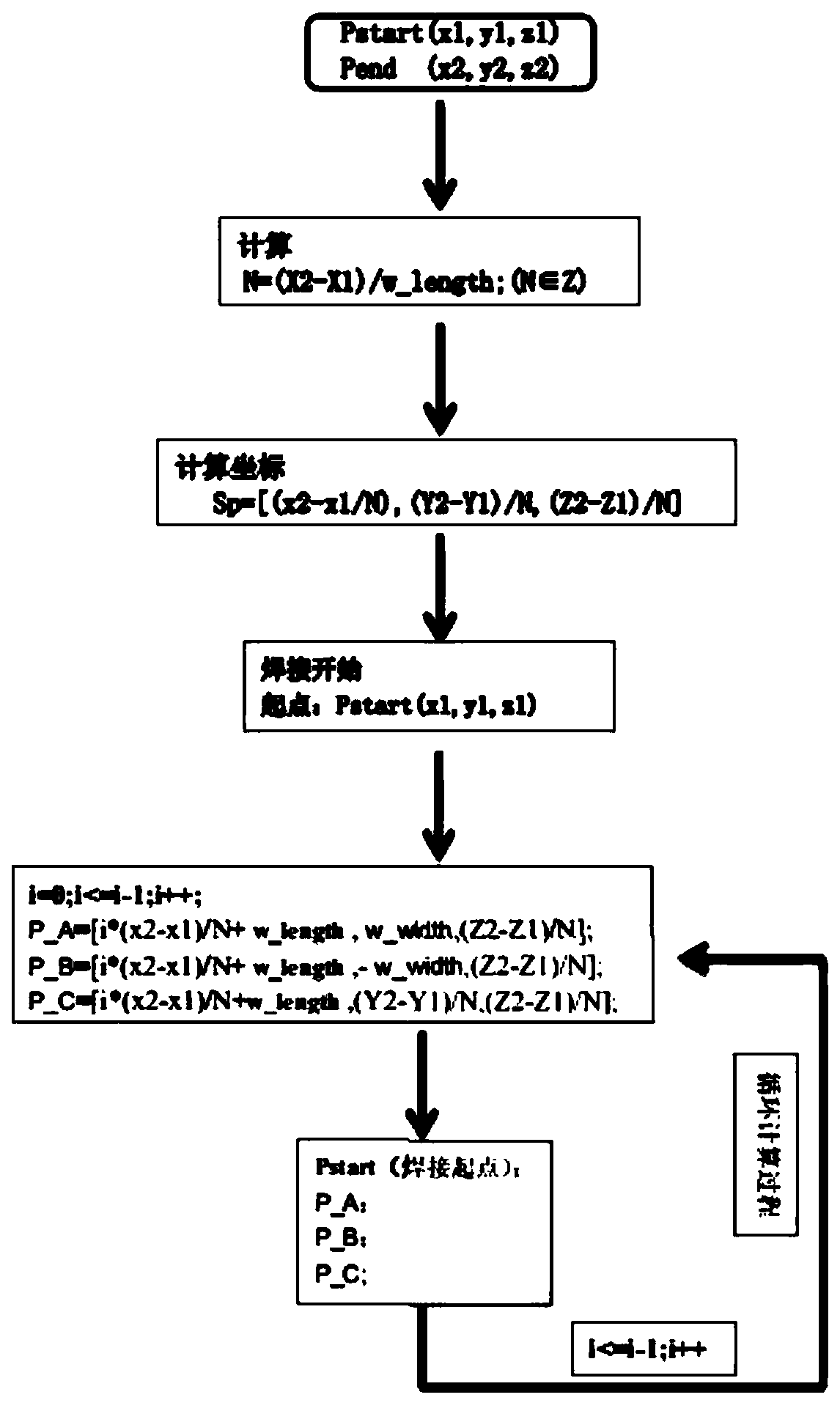

[0018] Call the preset detection sensor to detect welding position information; establish a spatial rectangular coordinate system according to the position information, and calculate the coordinates of each welding point on the position according to the preset step width of the welding torch; according to the calculated coordinates of each welding point , generating a swing path corresponding to the welding gun, and controlling the welding gun to perform welding along the swing path. The calculation method of the swing path is as follows: first teach the starting point Pstart, the end point Pend, the step size w_length, and the swing width w_width of the required welding position on the ...

Embodiment 2

[0020] Divide the welding seam into several sub-welding seams, use the length of the sub-welding seams as the step width of the welding torch, and calculate the coordinates of each welding point on the measurement position plane on both sides of the measurement position.

[0021] In this embodiment, the above-mentioned welding seam can be divided into several sub-welding seams, and the length of the sub-welding seam can be used as the step width of the welding torch, and the coordinates of each welding point on the measurement position plane on both sides of the above-mentioned measurement position can be calculated. According to the calculated coordinates of each welding point, a swing path corresponding to the welding torch is generated, and the welding gun is controlled to perform welding along the swing path.

[0022] In the embodiment, after calculating the coordinates of each welding point on the measurement position surface on both sides of the above-mentioned measuremen...

Embodiment 3

[0025] First, teach the start point Pstart, end point Pend, step length w_length, and swing width w_width of the required welding part on the robot, and then calculate the path by remembering the start point, end point, swing width, and step length, and calculate the step length coordinate Sp. When calculating Define three coordinates as P_A, P_B, and P_C, and finally calculate P_A, P_B, and P_C in the loop statement and perform welding according to the coordinates of the calculation results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com