Preparation method of metal pipe fittings not prone to deform

A metal pipe fitting and hard-to-deform technology, which is applied in the field of the preparation of hard-to-deform metal pipe fittings, and can solve the problems of complex structure of components, low production efficiency, and easy oxidation of welds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a difficult-to-deform metal pipe fitting, the difficult-to-deform metal pipe fitting includes a hard-to-deform metal reducing pipe and a blind hole pipe, comprising the following steps:

[0029] According to the structural parameters of the difficult-to-deform metal pipe fittings, the integral part is split into not less than two split parts, and then the split parts are prepared according to the structural characteristics of the split parts;

[0030] After performing friction welding on each split part, the burr at the weld seam is removed to obtain the hard-to-deform metal pipe fitting.

[0031] According to the structural parameters of the difficult-to-deform metal pipe fittings, the present invention divides the integral part into no less than two split parts, and then prepares the split parts according to the structural characteristics of the split parts. In the present invention, the material of the difficult-to-deform...

Embodiment 1

[0042] Ti6246 titanium alloy tube and Ti6246 titanium alloy rod were friction welded to prepare blind hole tube.

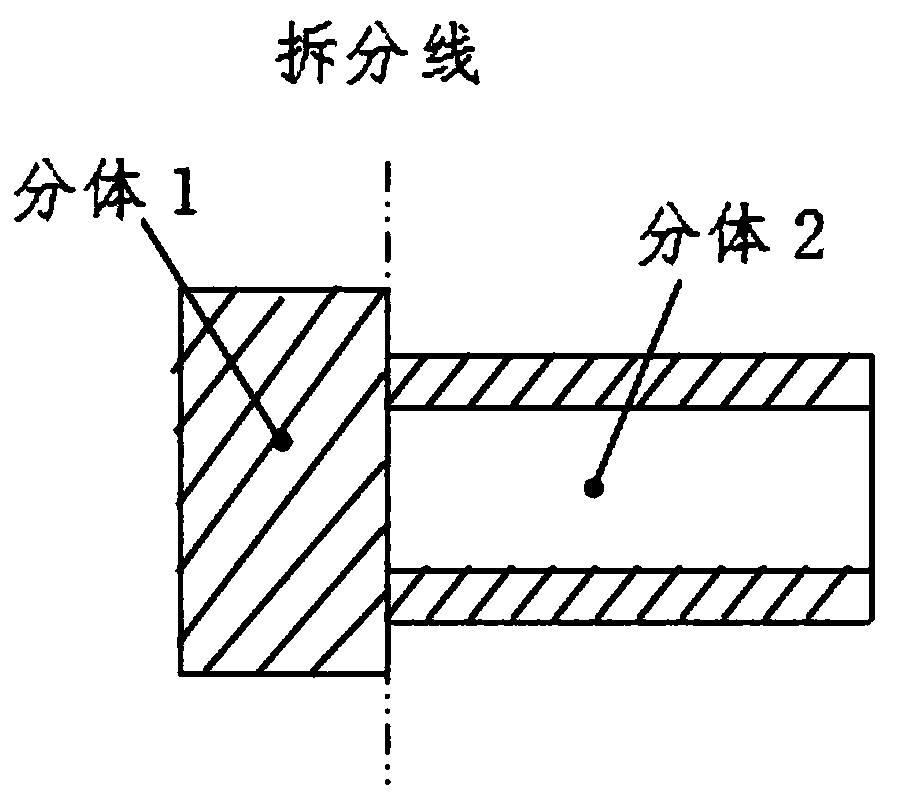

[0043] Step 1, the structural diagram of the Ti6246 titanium alloy blind hole tube, such as figure 1 As shown, the schematic diagram of the structure disassembly of Ti6246 blind hole tube is as follows figure 2 shown. Split the structure into two splits, split 1 is a rod of Φ200mm×80mm, and split 2 is a pipe of Φ160mm×16mm. The split body 1 is prepared by forging, the split body 2 is prepared by extrusion, the split body 1 bar and the split body 2 pipe required for preparing the blind hole pipe are cut out, and a welding shortening margin is reserved.

[0044]Step 2. One of the two split parts to be welded is clamped on the rotating fixture, and the other is clamped on the moving fixture, the process parameters of friction welding are set, and the friction welding equipment is started. The rotating workpiece starts to rotate at a high speed of 900rpm under the...

Embodiment 2

[0050] Fabrication of pure titanium reducer by friction welding.

[0051] Step 1, the structural diagram and disassembly diagram of the pure titanium variable diameter tube, such as Figure 6 As shown, the structure is split into three splits. Split 1 is a pipe of Φ200mm×10mm×200mm, split 3 is a pipe of Φ500mm×10mm×200mm, split 2 is a variable diameter pipe with a small end of Φ200mm, a large end of Φ500mm, a wall thickness of 10mm, and a length of 400mm. Split 1 adopts the method of extrusion + rolling to prepare pipes, and cuts out the pipes required for the preparation of special-shaped pipes; Split 2 is prepared by die forging or spinning; Split 3 is prepared by forging rings or rolling rings . A certain amount of welding shortening margin is reserved when each split is cut.

[0052] Step 2: Clamp the splits 1 and 2 to be welded on the rotating fixture and the moving fixture respectively, set the process parameters of friction welding, and start the friction welding equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com