Method for reinforcing wood powder/polyolefin composite material by utilizing surface-treated continuous aramid fibers

An aramid fiber and composite material technology is applied in the field of reinforced wood flour/polyolefin composite materials, which can solve the problems of affecting the strength of the aramid fiber surface structure itself, high cost, and poor bonding strength between the fiber and the wood-plastic matrix interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

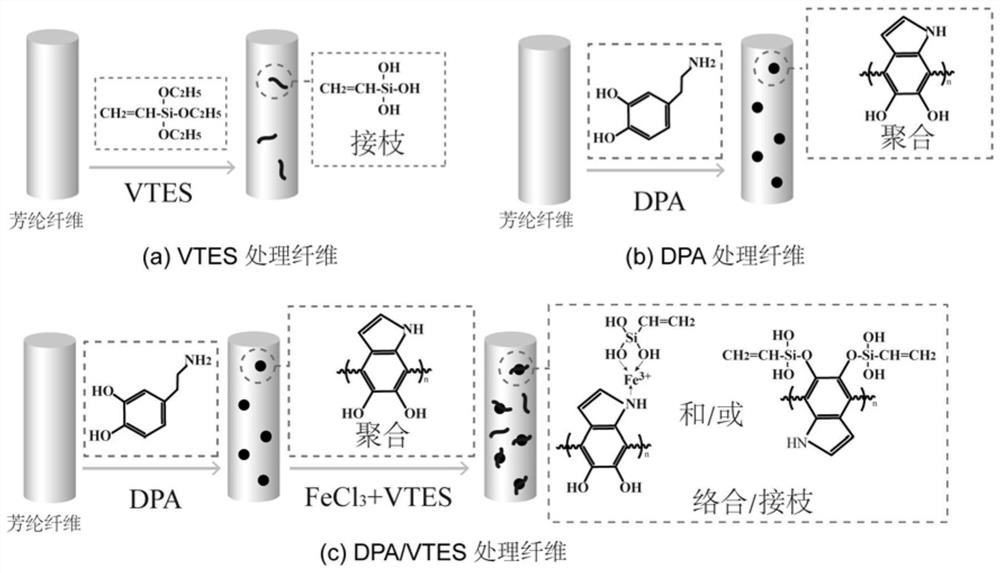

[0033] Specific embodiment one: a kind of method utilizing the continuous aramid fiber of surface treatment in this embodiment to strengthen wood powder / polyolefin composite material, it carries out according to the following steps:

[0034] 1. Pretreatment:

[0035] washing the continuous aramid fiber bundle with a solvent to remove surface impurities, and then drying to constant weight to obtain the pretreated continuous aramid fiber bundle;

[0036] 2. Continuous aramid fiber bundles coated with dopamine:

[0037] Adjust the pH of the Tris-HCl buffer solution to 8-9 to obtain a Tris-HCl buffer solution after adjusting the pH, then add dopamine hydrochloride to the Tris-HCl buffer solution after adjusting the pH to obtain a dopamine hydrochloride solution. The continuous aramid fiber bundle is immersed in the dopamine hydrochloride solution, soaked at room temperature for 2 hours to 48 hours, taken out after dipping, washed and dried, and the continuous aramid fiber bundle ...

specific Embodiment approach 2

[0049] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the continuous aramid fiber bundle described in step 1 is 1000D continuous aramid fiber bundle, wherein D is the linear density unit, referring to the length of the 9000m long fiber bundle Mass, in g. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0050] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: a continuous aramid fiber bundle consists of 666 single fibers. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interfacial shear strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com