Self-adaptive variable-mode sewage treatment method for combined sewage system

A sewage treatment method and technology of sewage system, which are applied in the field of self-adaptive variable mode sewage treatment, can solve the problems of increasing land occupation and construction funds, etc., so as to increase the treatment load of the whole plant, the volume load is high, and the flow load and water quality load can be improved. The effect of the ability to change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

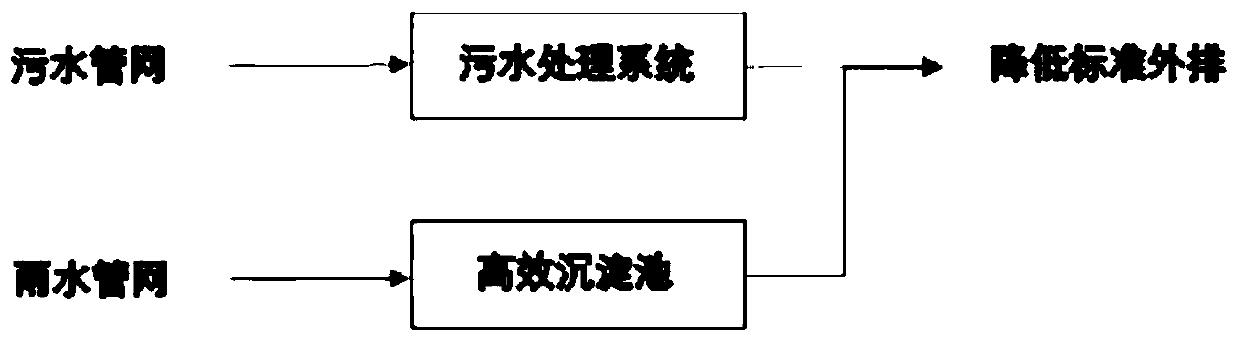

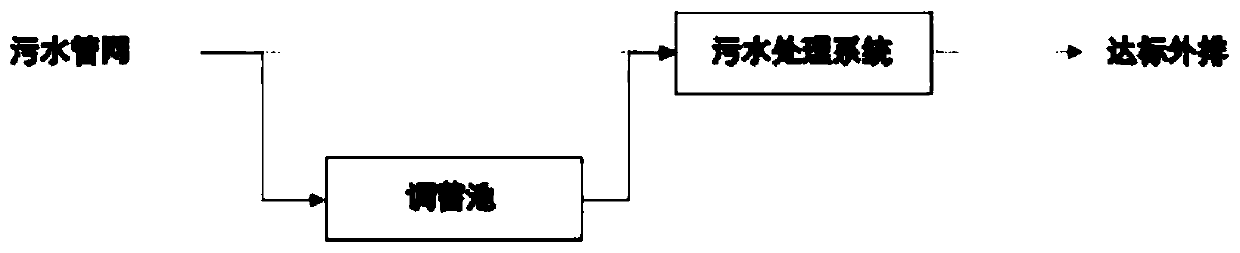

Problems solved by technology

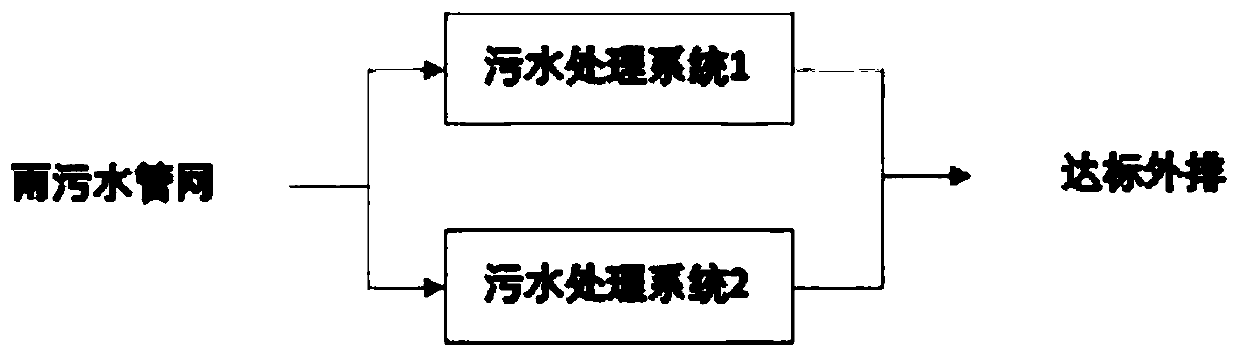

Method used

Image

Examples

Embodiment 1

[0059] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly. The English abbreviation of the "Adaptive Variable Mode Sewage Treatment Method for Consolidated Sewage System" is "D / W-AA / O" process.

[0060] Example 1

[0061] A specific embodiment of the self-adaptive variable mode sewage treatment method of the combined sewage system of the present invention, comprising a pretreatment facility 1, an anaerobic section of the biochemical pool 2, an anoxic section of the biochemical pool 3, an aerobic section of the biochemical pool 4, a biochemical Pool adaptive section 5, secondary sedimentation tank 6, bypass sludge relay tank 7, bypass phosphorus removal tank 8; pretreatment facility 1, anaerobic section 2, ...

Embodiment 2

[0074] The present invention also provides the self-adaptive section of the sewage treatment biochemical pool and its special device embedded with the sewage treatment method of the above-mentioned combined sewage system self-adaptive variable mode, and the specific embodiments of the self-adaptive section of the sewage treatment biochemical pool and its special device include : 1. The self-adaptive section of the biochemical pool 2. The special device for the self-adapted section. 3. The connection between the self-adaptive special device and the backflow system in the sewage treatment biochemical pool

[0075]One of the innovations of the present invention is: setting an adaptive section in the sewage treatment biochemical pool, and configuring a special device in the adaptive section. The problem to be solved is: rational use of gravity and the energy of the internal return system to control the average activated sludge concentration of the biochemical pool at 6000-8000 mg / L...

specific Embodiment approach

[0077] The specific implementation method comprises the following steps:

[0078] In step (1), an adaptive section is set at the end of the biochemical tank. The activated sludge mixture in the adaptive section can enter the secondary sedimentation tank through the overflow adjustable weir, and the activated sludge mixture in the adaptive section can pass customs and return internally. The connection of the pipe enters the anaerobic section or the anoxic section at the front end of the biochemical pool;

[0079] In step (2), the special device for the self-adaptive section is movable within a certain horizontal distance interval, and the moving distance is steplessly adjustable; the setting of the moving distance interval is self-adapting to the peak flow rate and trough flow rate of the sewage treatment plant;

[0080] Step (3), the front-end adjustable weir and the rear-end overflow adjustable weir of the self-adaptive section of the biochemical pool can be adjusted within a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com