Mixed slurry for constructional engineering, and preparation method thereof

A technology for construction engineering and mixing slurry, applied in the field of construction engineering slurry, can solve the problems of poor waterproof and anti-corrosion properties of slurry, and achieve the effect of improving waterproof and anti-corrosion effect, improving integration, improving strength, temperature stability and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one, with reference to figure 1 , a kind of mixed slurry for construction engineering, including cement, emulsified asphalt and gelatin mixed slurry made by mixing.

[0030] Wherein, the components in the mixed slurry are as follows: 100-200 parts of cement, 20-50 parts of emulsified asphalt and 5-10 parts of gelatin.

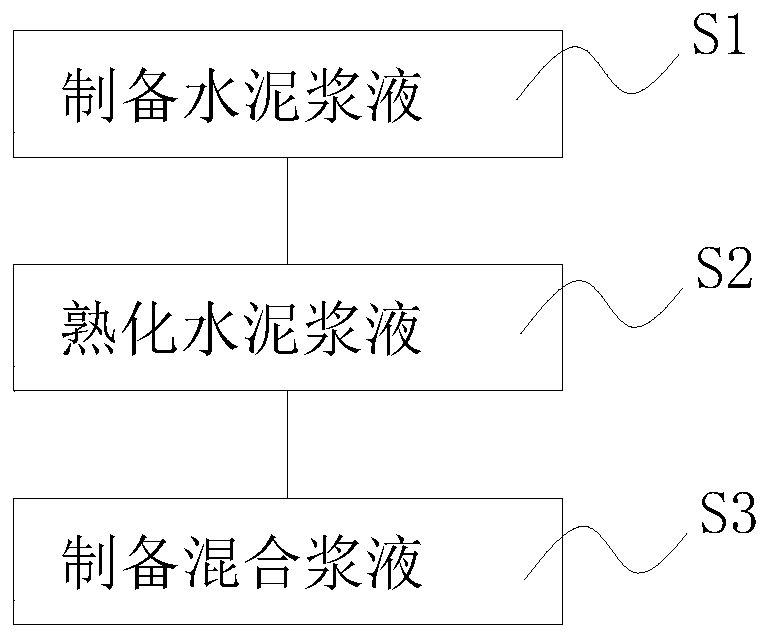

[0031] A method for preparing mixed slurry for construction engineering, comprising the steps of:

[0032] S1, preparing cement slurry, taking 100-200 parts of cement and an appropriate amount of water in proportion, mixing and stirring to obtain cement slurry;

[0033] S2, curing the cement slurry, heating the cement slurry at a low temperature;

[0034] S3. Add 20-50 parts of emulsified asphalt and 5-10 parts of gelatin in batches, and stir evenly to obtain a mixed slurry.

[0035] Wherein, the aging temperature in S2 is controlled between 30-40°C.

Embodiment 2

[0036] Embodiment two, refer to Figure 1~2 , a kind of mixed slurry for construction engineering, including cement, emulsified asphalt and gelatin mixed slurry made by mixing.

[0037] Wherein, the components in the mixed slurry are as follows: 100-200 parts of cement, 20-50 parts of emulsified asphalt and 5-10 parts of gelatin.

[0038] Wherein, the mixed slurry further includes additives, and the additives include modifiers.

[0039] Wherein, the modifier component is 1-5 parts.

[0040] Wherein, the modifying agent includes resin, high molecular polymer and ground rubber powder.

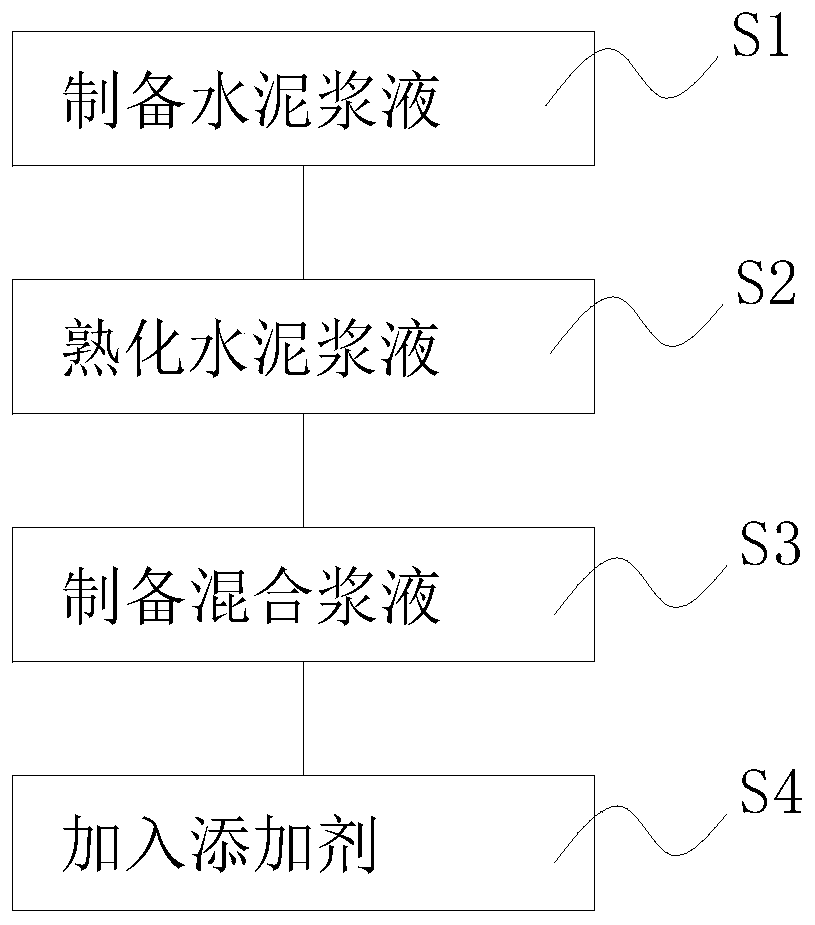

[0041] A method for preparing mixed slurry for construction engineering, comprising the steps of:

[0042] S1, preparing cement slurry, taking 100-200 parts of cement and an appropriate amount of water in proportion, mixing and stirring to obtain cement slurry;

[0043] S2, curing the cement slurry, heating the cement slurry at a low temperature;

[0044] S3. Add 20-50 parts of emulsified as...

Embodiment 3

[0047] Embodiment three, refer to Figure 1~2 , a kind of mixed slurry for construction engineering, including cement, emulsified asphalt and gelatin mixed slurry made by mixing.

[0048] Wherein, the components in the mixed slurry are as follows: 100-200 parts of cement, 20-50 parts of emulsified asphalt and 5-10 parts of gelatin.

[0049] Wherein, the mixed slurry further includes an additive, and the additive is a water-repellent agent.

[0050] Wherein, the water-repellent component is 1-2 parts of water-repellent.

[0051] Wherein, the modifying agent is a water-repellent agent, and the water-repellent agent is one or both of organosilicon-based water-repellent agents and calcium stearate.

[0052] A method for preparing mixed slurry for construction engineering, comprising the steps of:

[0053] S1, preparing cement slurry, taking 100-200 parts of cement and an appropriate amount of water in proportion, mixing and stirring to obtain cement slurry;

[0054] S2, curing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com