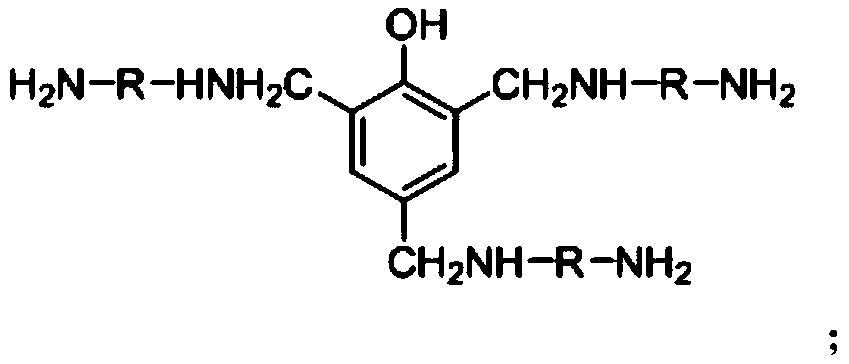

Phenolic aldehyde modified polyether amine type epoxy resin curing agent and preparation method thereof

An epoxy resin curing and phenolic modification technology, which is applied in the field of epoxy resin preparation, can solve the problems of unsatisfactory high temperature performance and achieve excellent bonding performance and mechanical properties, low volatility, and moderate curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) In a 500mL three-necked flask equipped with a stirrer, reflux condenser, thermometer and dripping device, according to n (amine): n (aldehyde): n (phenol) = 0.75mol: 0.75mol: 0.25mol, add 111.0g of polyetheramine EDR-148 and 23.5g of phenol were stirred while raising the temperature, and the stirring speed was 100-200 rpm.

[0023] (2) When the temperature rose to 75-85° C., 75.1 g of 30% formaldehyde solution was added dropwise at a rate of 1 drop / second, and the reaction was refluxed at 95-105° C. for 4 hours.

[0024] (3) Then the reaction kettle is connected to a vacuum distillation device, vacuum dehydration is carried out, and the distillation is stopped until the liquid phase temperature is 120° C. to obtain the product.

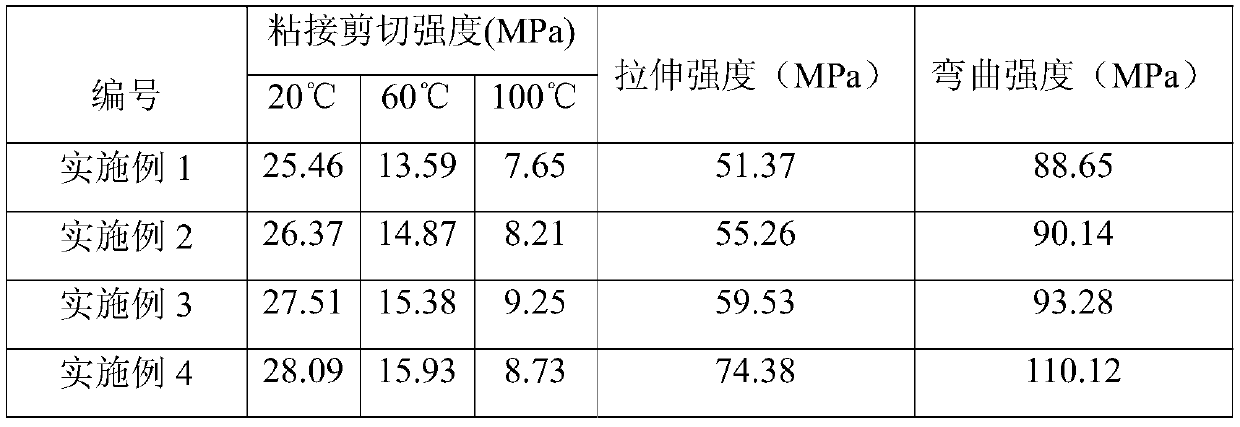

[0025] Performance test: The obtained modified amine curing agent is used in conjunction with bisphenol A epoxy resin (E-51) to form an adhesive, and its bonding performance is studied by measuring the shear strength and peel strength. The...

Embodiment 2

[0029] (1) In a 500mL three-necked flask equipped with a stirrer, reflux condenser, thermometer and dripping device, according to n (amine): n (aldehyde): n (phenol) = 0.75mol: 0.75mol: 0.25mol, add 132.0g of polyetheramine EDR-176 and 23.5g of phenol were stirred while raising the temperature, and the stirring speed was 100-200 rpm.

[0030] (2) When the temperature rose to 75-85° C., 75.1 g of 30% formaldehyde solution was added dropwise at a rate of 1 drop / second, and the reaction was refluxed at 95-105° C. for 4 hours.

[0031] (3) Then the reaction kettle is connected to a vacuum distillation device, vacuum dehydration is carried out, and the distillation is stopped until the liquid phase temperature is 120° C. to obtain the product.

[0032] Performance test: The modified amine curing agent obtained above was used in conjunction with bisphenol A epoxy resin (E-51) to form an adhesive, and its bonding performance was studied by measuring the shear strength and peel streng...

Embodiment 3

[0036] (1) In a 500mL three-necked flask equipped with a stirrer, reflux condenser, thermometer and dripping device, according to n (amine): n (aldehyde): n (phenol) = 0.75mol: 0.75mol: 0.25mol, add 144.0g of polyetheramine EDR-192 and 23.5g of phenol were stirred while raising the temperature, and the stirring speed was 100-200 rpm.

[0037] (2) When the temperature rose to 75-85° C., 75.1 g of 30% formaldehyde solution was added dropwise at a rate of 1 drop / second, and the reaction was refluxed at 95-105° C. for 4 hours.

[0038] (3) Then the reaction kettle is connected to a vacuum distillation device, vacuum dehydration is carried out, and the distillation is stopped until the liquid phase temperature is 120° C. to obtain the product.

[0039] Performance test: The modified amine curing agent obtained above was used in conjunction with bisphenol A epoxy resin (E-51) to form an adhesive, and its bonding performance was studied by measuring the shear strength and peel streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com