Water-dispersible two-component polyurea coating composition with excellent weather resistance and elasticity as well as preparation method and application thereof

A weather resistance, composition technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve the effect of improving strength, improving working environment, and eliminating fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

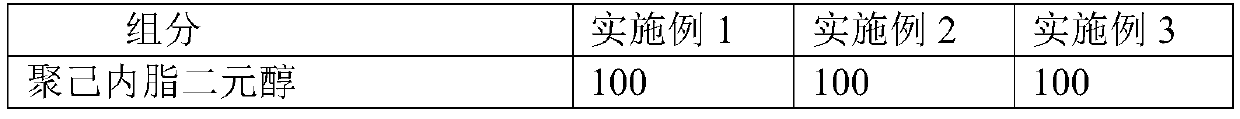

[0024] Embodiment 1~3 prepares curing agent component B

[0025] 1. The formula of component B is shown in Table 1

[0026] Table 1

[0027]

[0028]

[0029] 2. Preparation process

[0030] Put polycaprolactone diol and amino-terminated methoxy polyether at 105°C with nitrogen for vacuum dehydration, then add aliphatic polyisocyanate or aliphatic or alicyclic diisocyanate at one time, and react at 80°C for 6 hours Make component B.

Embodiment 4~5

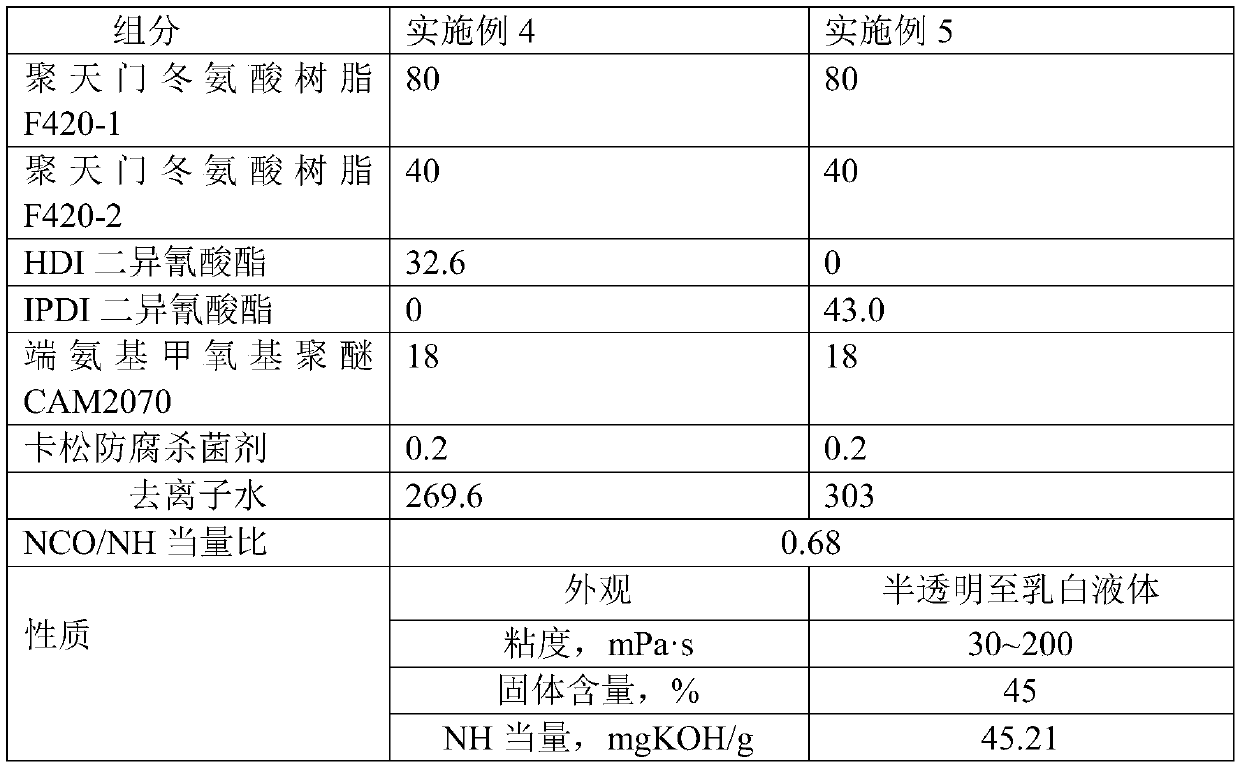

[0031] Embodiment 4~5 prepares component A

[0032] 1. Component A formula Table 2

[0033]

[0034] Note: Polyaspartic acid resin F420-1 and polyaspartic acid resin F420-2 in Table 2 both refer to polyaspartic acid resin F420, which are added in two times, so they are replaced by different numbers.

[0035] 2. Synthesis process: put polyaspartic acid resin F420-1 and aminomethoxy terminated polyether CAM2070 into a clean reactor with heating and cooling device, thermometer, stirrer and inert gas introduction pipe according to the ratio in Table 2. Raise the temperature to 105°C for 2 hours, vacuumize and dehydrate with nitrogen, then lower the temperature to below 40°C, then add HDI diisocyanate or IPDI diisocyanate at one time, react at no higher than 40°C for 1 hour, then slowly raise the temperature to 80°C and react for 6 hours Then lower the temperature to below 40°C and then put polyaspartic acid resin F420-2 into it, react at no higher than 40°C for 1 hour, then sl...

Embodiment 6~7

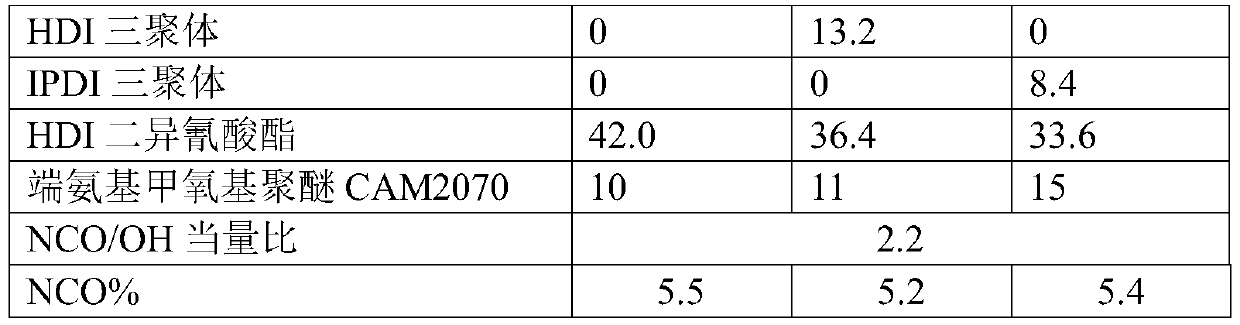

[0037] 1. Coating formula see Table 3

[0038] table 3

[0039]

[0040] 2. Process

[0041] According to the ratio in Table 3, after mixing the water dispersion of component A with rutile titanium dioxide R902 evenly, grind it in a sand mill to a fineness of ≤20 μm, then add other additives and stir evenly, then add component B in proportion, and use Deionized water is adjusted to the application viscosity to obtain the coating composition of the present invention.

[0042] 3. Coating performance inspection

[0043] (1) The sample is prepared according to the national paint testing standards;

[0044] (2) Preparation of elastic film

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com