Method for automatically controlling switching of large valve of ethylene cracking furnace

An ethylene cracking furnace, automatic control technology, applied in non-electric variable control, electric fluid pressure control, hydrocarbon cracking to produce hydrocarbons, etc. problems to achieve the effect of ensuring flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

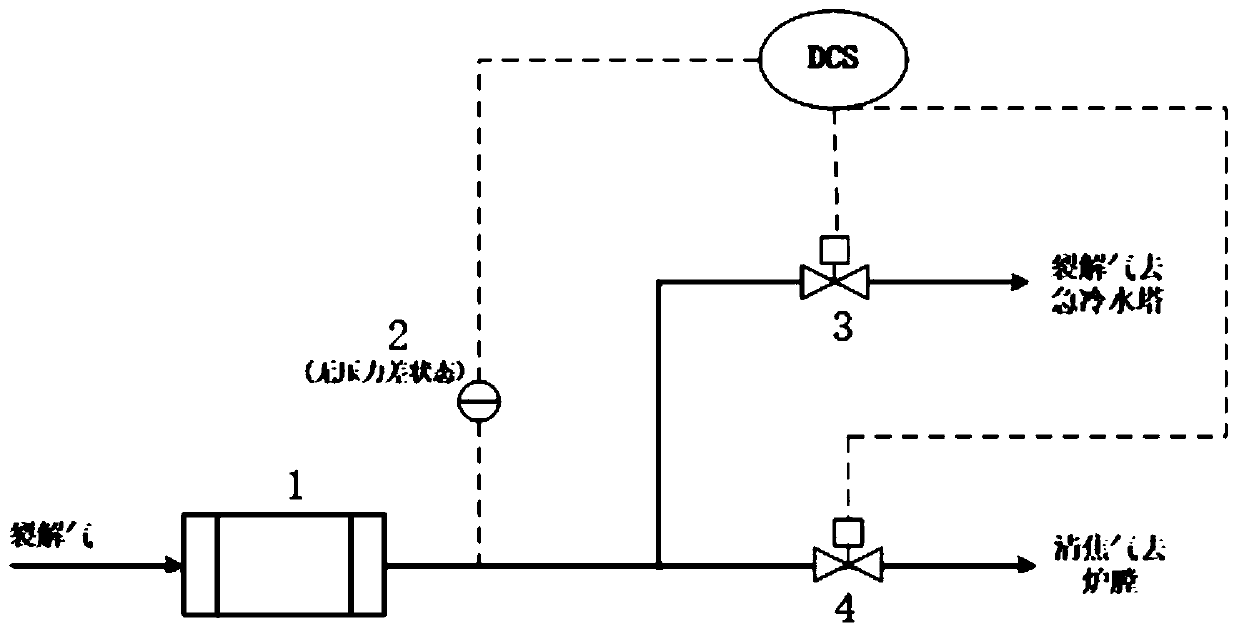

[0036] Taking the large valve switching control process of a 1 million t / h ethylene cracking furnace in a factory as an example, the steps are as follows:

[0037] (1) Initialization and initial permissibility work inspection are carried out first, so that the cracked gas valve and other related valves are in normal working condition, and at the same time, the furnace COT, dilution steam flow rate, furnace negative pressure, furnace SS temperature, large valve pressure difference, large valve The anti-coking steam pressure parameters are within the range of process requirements, and confirm the preparation status of related blind plates and root valve utilities;

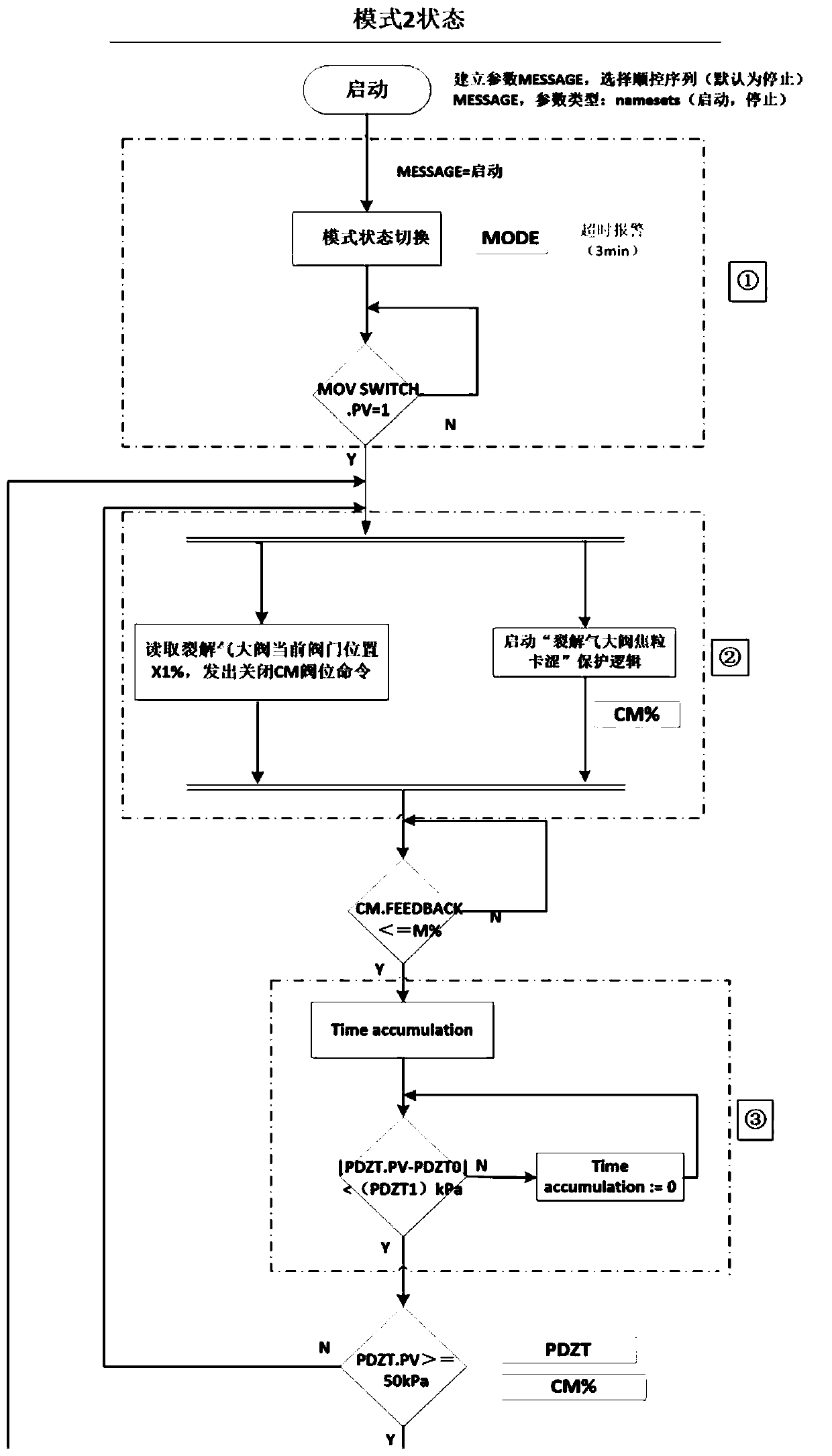

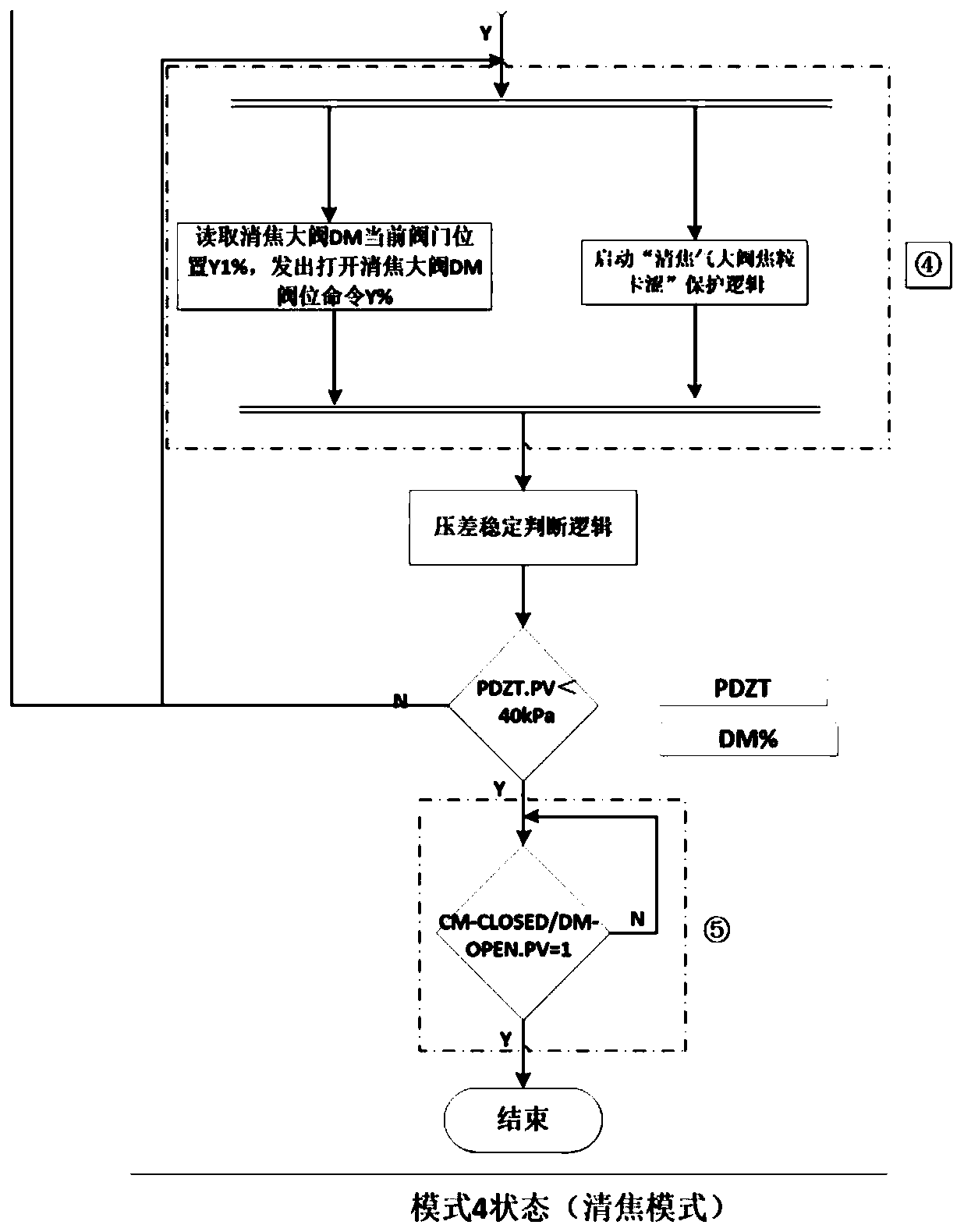

[0038] (2) Switch the cracking furnace mode from the hot standby mode to the large valve automatic switching mode. After detecting the status feedback parameters of the large valve automatic switching mode, a command to close the cracking gas large valve is issued based on the DCS, and at the same time start the pyrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com