A kind of deplating solution and deplating process for removing nickel layer on copper surface

A technology for stripping solution and copper surface, applied in the field of metal surface treatment, can solve the problems of low stripping efficiency and copper layer corrosion, and achieve the effect of high stripping efficiency and offsetting negative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

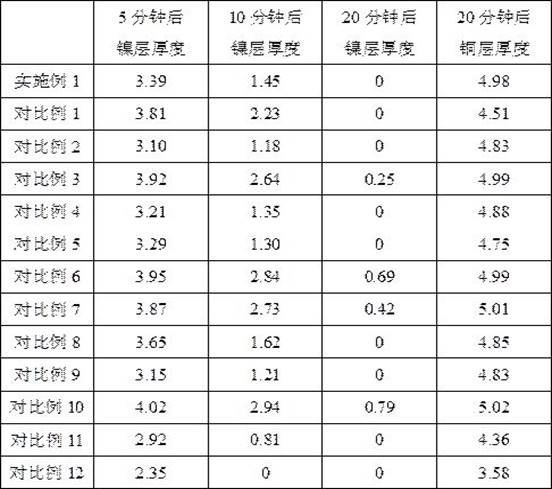

Examples

Embodiment 1

[0012] A stripping solution for removing a nickel layer on a copper surface, obtained by mixing uniformly the following raw materials in parts by weight: 25 parts of sodium bromide, 8 parts of oxidizing agent, 8 parts of tartaric acid, 0.8 part of urea, and 0.3 part of benzotriazole , 0.2 parts of cobalt acetate and 50 parts of water; the oxidizing agent is a mixture of 30wt% aqueous hydrogen peroxide, manganese dioxide and sodium perbromate in a mass ratio of 20:3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com