Dyeing process of crystal linen fabric

A technology of crystal linen and fabrics, which is applied in the field of textiles, can solve the problems affecting the color fastness of crystal linen, and achieve the effects of improving color fastness, enhancing effect, and enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

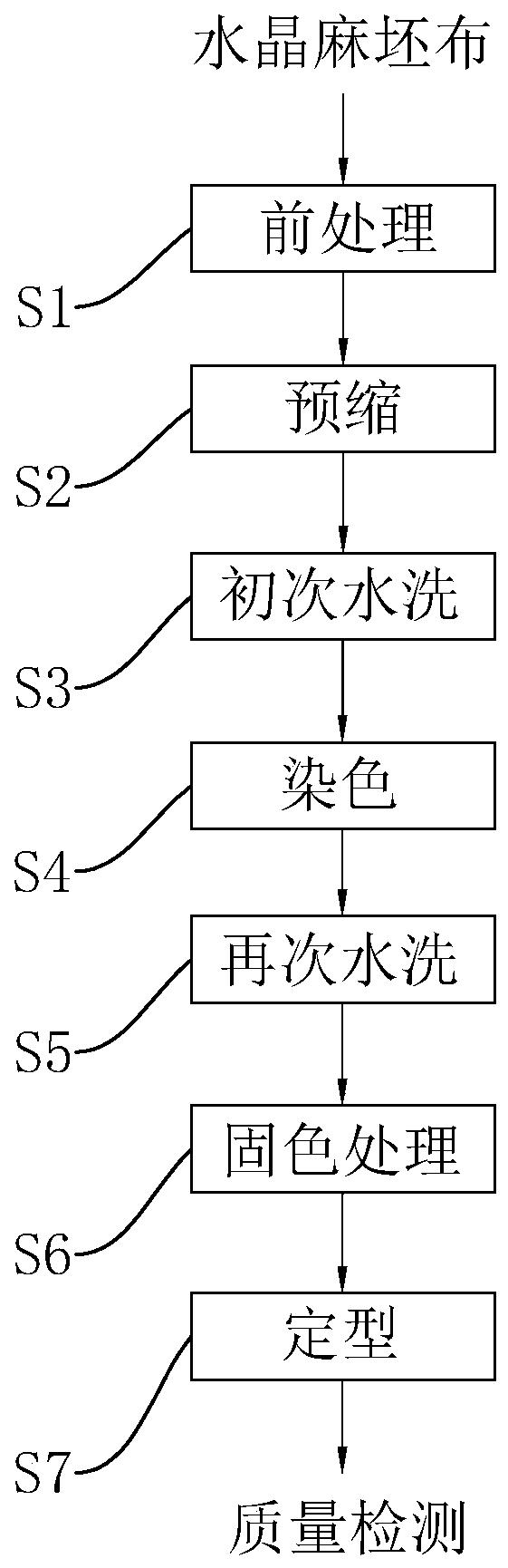

[0038] refer to figure 1 , a dyeing process of crystal hemp fabric, the following steps are performed on the gray cloth: wherein the gray cloth is composed of 92% polyester and 8% spandex.

[0039]S1: pre-processing. The gray cloth is transported to the wrinkle removal machine for processing, the temperature in the wrinkle removal machine is adjusted to 180°C, and the wrinkle removal treatment is continued for 15 minutes.

[0040] S2: Pre-shrunk. The gray cloth after S1 treatment is transported to the high temperature and high pressure overflow dyeing machine, and then caustic soda solution is added into the high temperature and high pressure overflow dyeing machine for preshrinking treatment. The concentration of caustic soda is 1g / L, and the temperature is controlled at 110°C. for 2h.

[0041] S3: Initial washing. Rinse the gray cloth after S2 pre-shrinking with clean water for 10-15 minutes.

[0042] S4: Staining. Dyeing the gray cloth after the initial water washing ...

Embodiment 6

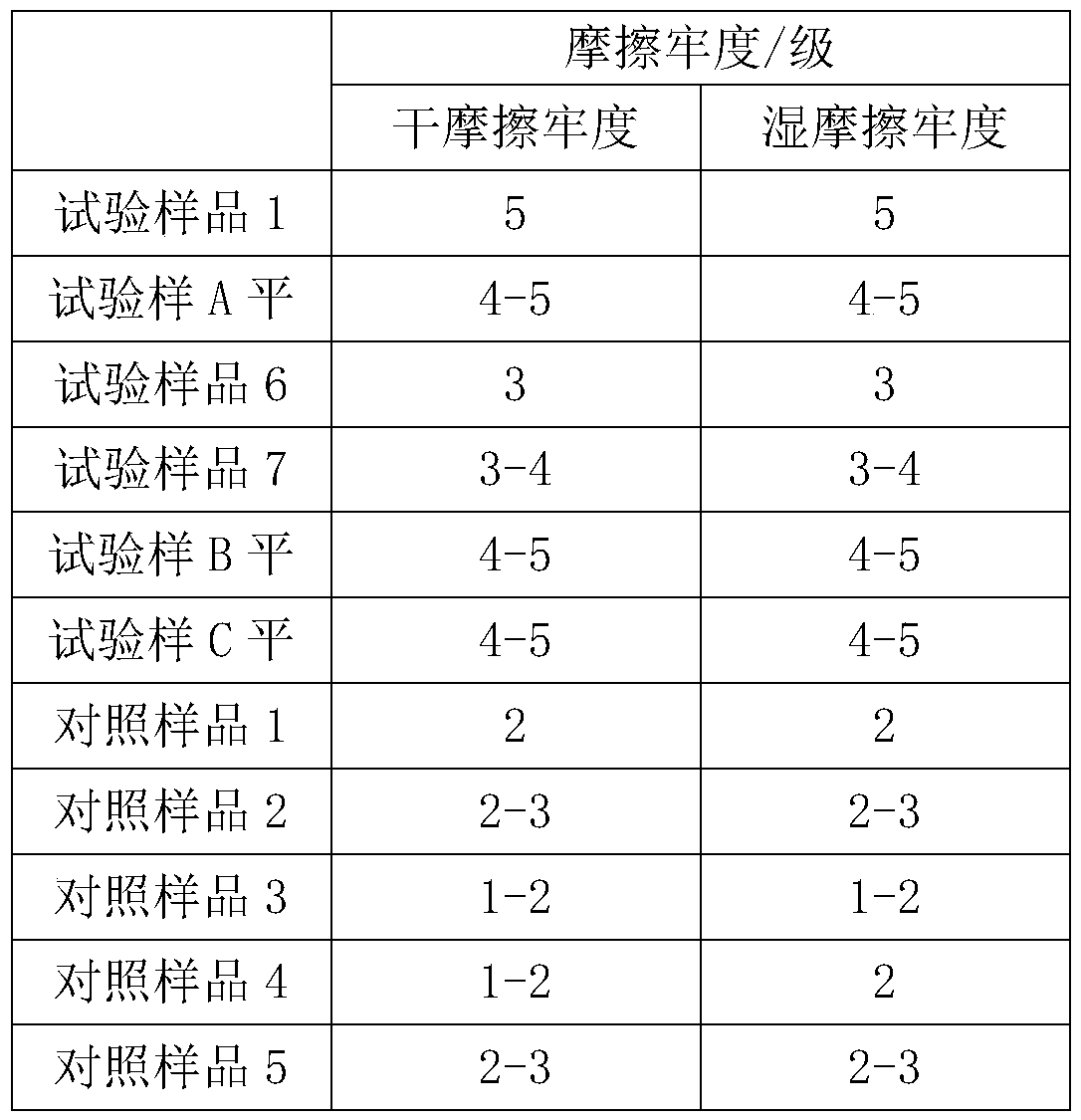

[0050] The difference between embodiment 6 and embodiment 1 is that there is no fatty alcohol polyoxyethylene ether and babassu oleamidopropyl betaine in the raw material of the dye used for dyeing in S4 dyeing.

Embodiment 7

[0051] The difference between Example 7 and Example 1 is that there is no ammonium polyacryloyl dimethyl taurate, fatty alcohol polyoxyethylene ether and babassu oleamidopropyl betaine in the raw materials of the dye used in the dyeing of S4.

[0052] The difference between embodiments 8-11 and embodiment 1 is that the raw materials of the reduction cleaning agent in S5 washing again are as shown in table 2 in parts by weight: unit: part

[0053] Table 2

[0054] Example 8 Example 9 Example 10 Example 11 sodium pyrophosphate 30 50 35 45 Glycerol 50 68 55 65 Sodium Polypropylene 23 47 29 41

[0055] The difference between Examples 12-15 and Example 1 is that the raw materials of the color-fixing agent in the S6 color-fixing treatment are as shown in Table 3 in parts by weight: unit: part

[0056] table 3

[0057] Example 12 Example 13 Example 14 Example 15 Pentaerythritol Stearate 14 30 18 26 sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com