Baking equipment for biomass processing

A biomass and baking technology, used in lighting and heating equipment, drying, dryers, etc., can solve the problems of drying speed, unfavorable heat dissipation, serious biomass contact accumulation, etc., and achieve fast drying speed. , The effect of drying fully and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

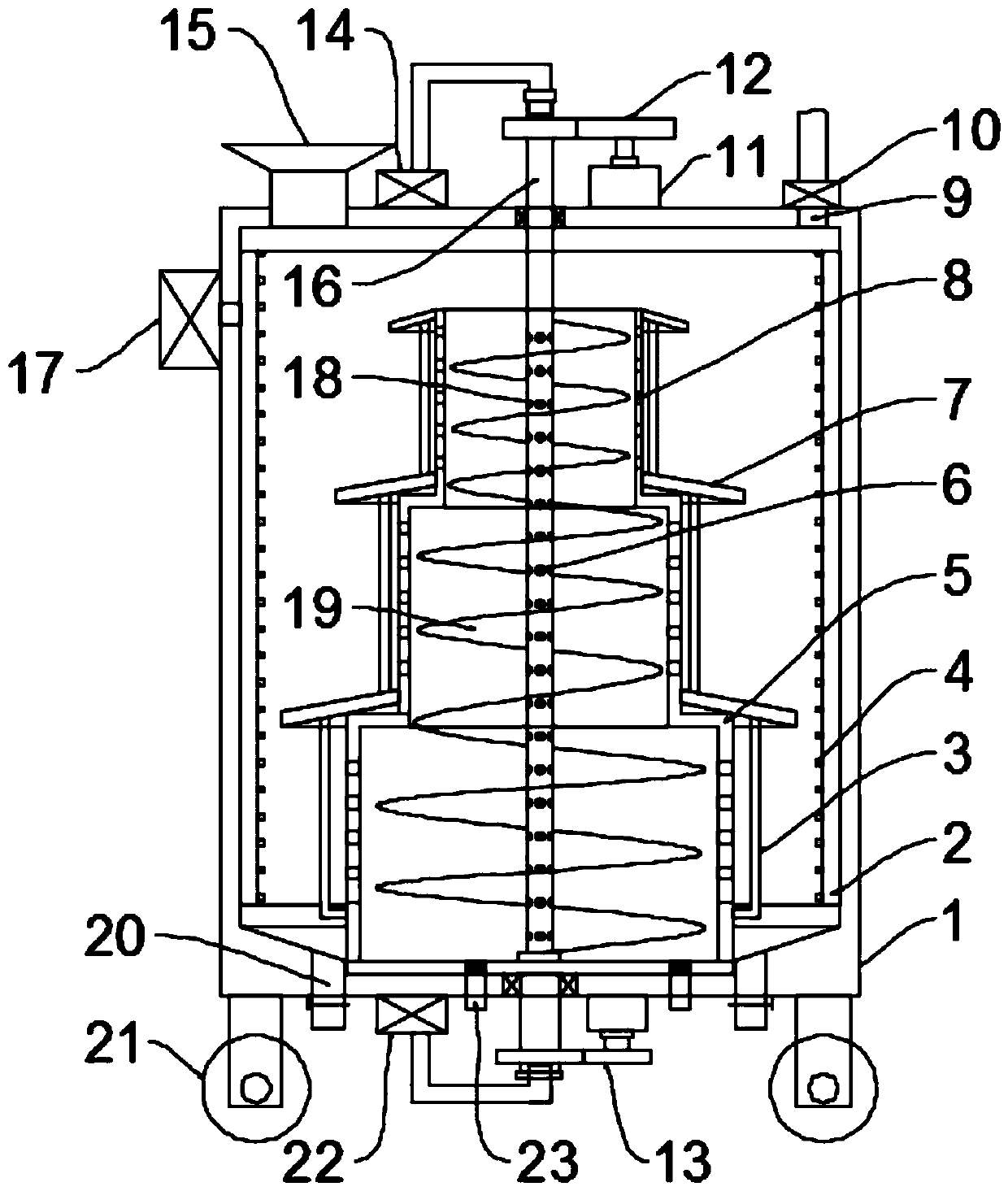

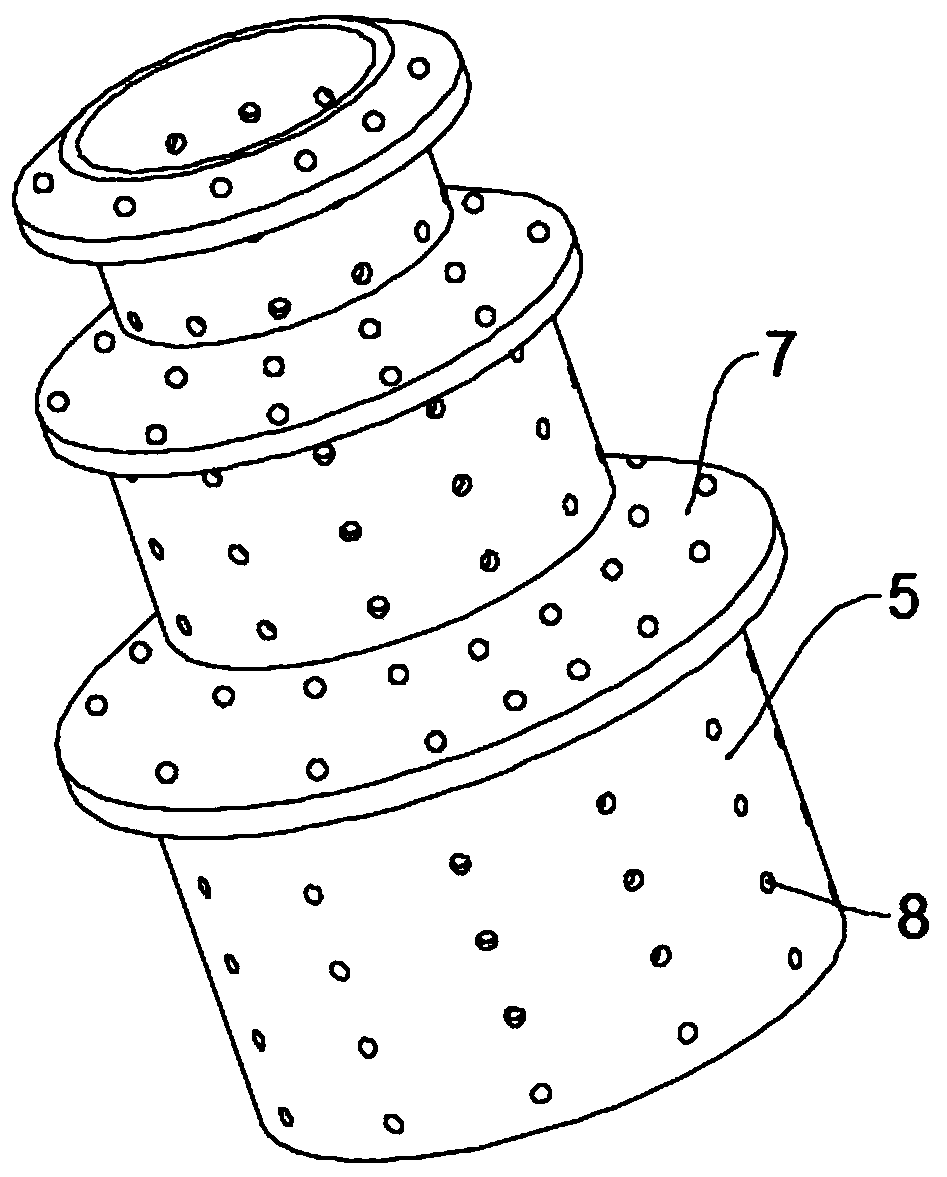

[0023] see Figure 1~2 , in an embodiment of the present invention, a baking equipment for biomass processing, including an outer cylinder 1 and a drying unit, the bottom of the outer cylinder 1 is evenly and symmetrically equipped with rollers 21, and the rollers 21 are self-locking rollers, To facilitate the movement of the device, the top of the outer cylinder 1 is provided with a feed hopper 15, the bottom of the outer cylinder 1 is provided with a discharge port 20, and a valve is installed on the discharge port 20, and the top of the external cylinder 1 is connected with a row The air pipe 9 is equipped with an exhaust fan 10 for accelerating the extraction of water vapor, and the drying unit includes a stepped inner cylinder 5, a rotating shaft 16, a lifting auger 19, a dispersion disc 7 and a hot air drying assembly , the stepped inner cylinder 5 is rotatably installed in the outer cylinder 1, the top opening of the stepped inner cylinder 5 is closed at the bottom, the...

Embodiment 2

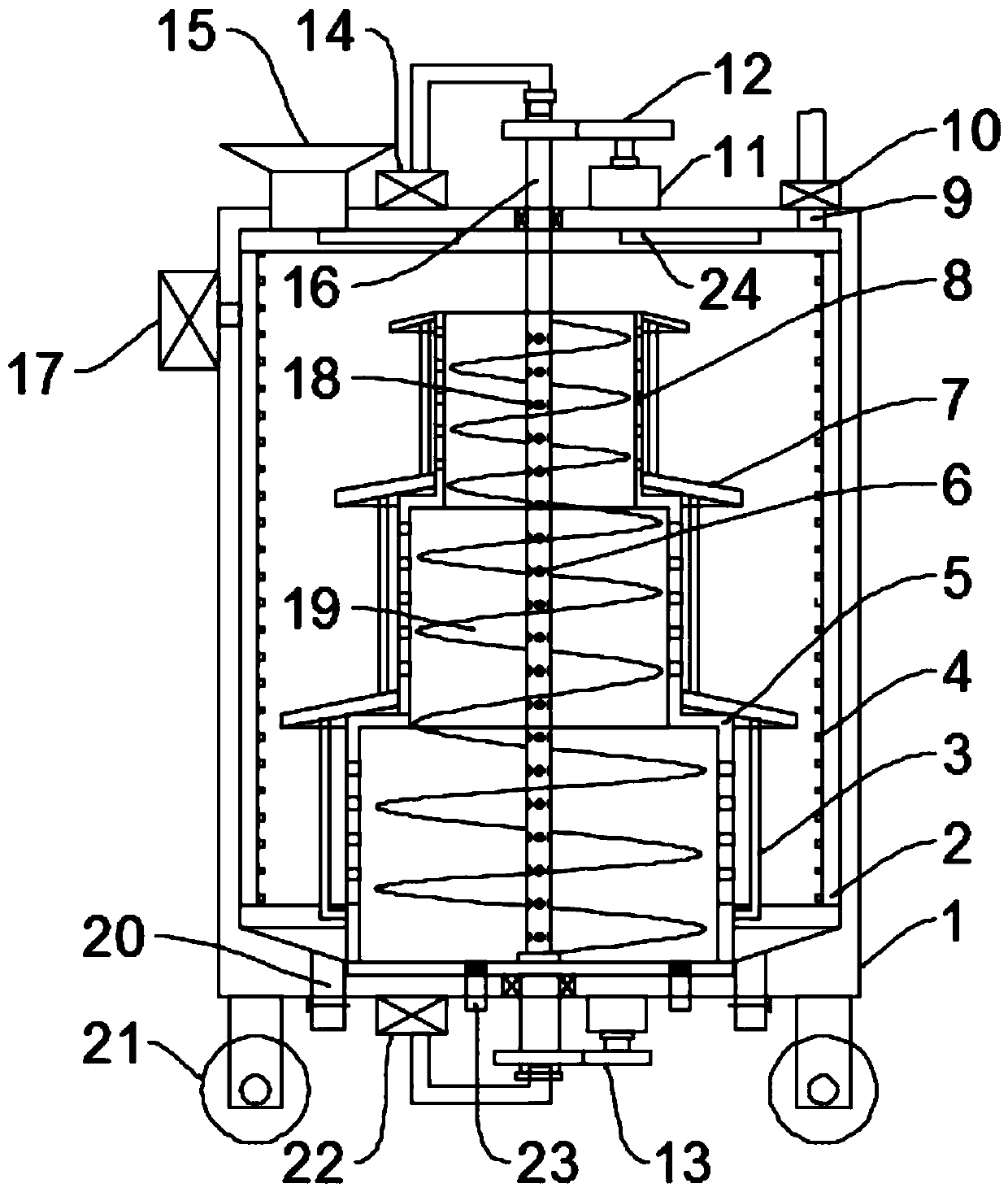

[0026] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that an electric heating element 24 is fixed on the top of the outer cylinder 1, and the electric heating element 24 further provides heat to facilitate drying.

[0027] The working principle of the present invention is: when working, the biomass is added into the outer cylinder body 1 from the feed hopper 15, and then enters the stepped inner cylinder 5 through the inlet, and drives the rotating shaft 16 and the lifting auger 19 to rotate through the first driving mechanism , the second driving mechanism 13 drives the stepped inner cylinder 5 to rotate in reverse, the biomass is lifted upwards, then scattered from the top of the stepped inner cylinder 5, and then falls from a plurality of dispersing discs 7 in turn, falling in the shape of a multi-layer curtain, and more It is better to contact with the hot air more fully, dry fully and evenly, and then enter the stepped inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com