Contact laser interference displacement sensor and measuring method

A technology of displacement sensor and laser interference, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems such as the inability to directly realize the measurement of large-size and high-precision parts, and achieve simple structure, extended range and precision, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

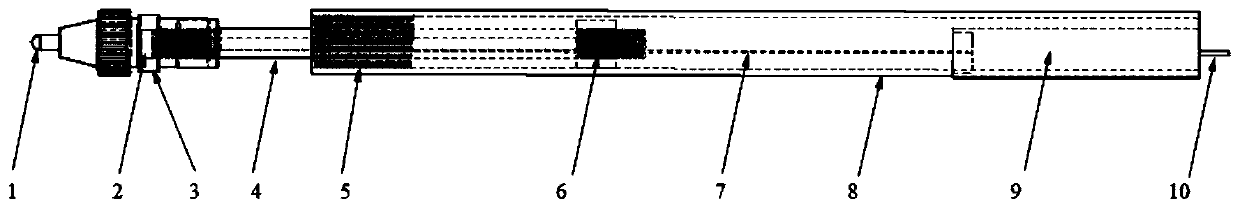

[0019] see figure 1 , the present invention is a contact laser interference displacement sensor, including a measuring sub 1, a mirror 2, a front limit block 3, a measuring rod 4, a rolling pair 5, a rear limit block 6, a laser beam 7, and a sensor sleeve 8 , a collimator 9, an optical fiber 10 and a frequency-modulated continuous wave interference signal processor. The front end of the measuring rod 4 is provided with a probe 1 and a reflector 2 in turn. The probe 1 and the measuring rod 4 are connected by threads at the front end. The mirror 2 and the measuring rod 4 are connected by thread or bonded. The measuring rod 4 is arranged on the sensor bushing 8 through the rolling pair 5 fixed at the front end of the sensor bushing 8, the measuring rod 4 is a hollow structure, the measuring rod 4 can move along the axial direction of the sensor bushing 8, and the The cross section of the rod 4 and the sensor bushing 8 is circular. The front limit block 5 and the rear limit blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com