A welded gas meter joint

A gas meter, welding technology, applied in the direction of instruments, measuring devices, volume measurement, etc., can solve the problems of reducing the service life of gas meters, increasing safety hazards, welding seam corrosion, etc., to achieve the best welding strength, increase consumption, increase The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

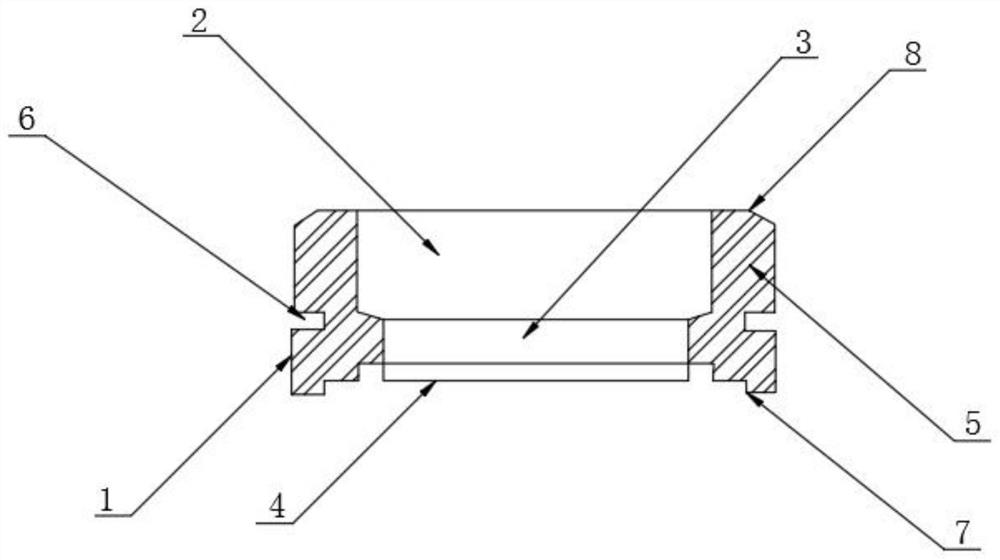

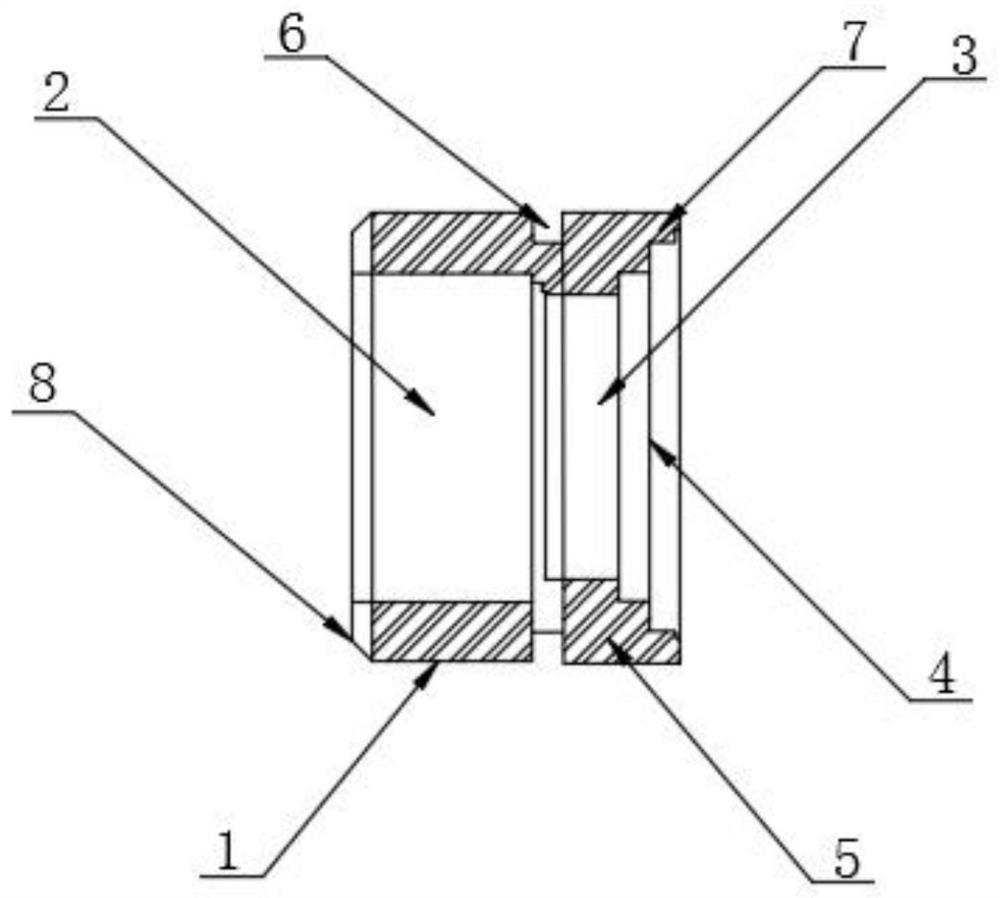

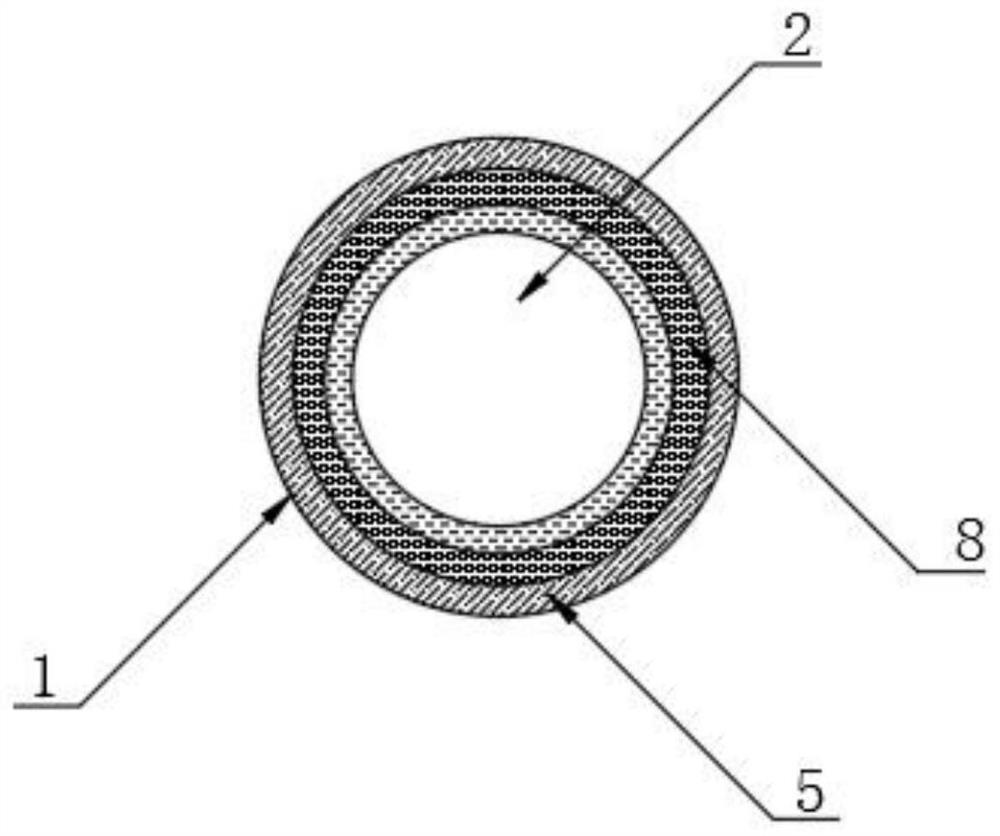

[0023] The present invention provides such Figure 1-4 The joint of a welded gas meter shown includes a joint main body 1, and a top connecting seat 2 and a bottom connecting seat 3 are arranged inside the joint main body 1, and the top connecting seat 2 and the bottom connecting seat 3 communicate with each other and the bottom The bottom of the connecting seat 3 is provided with a limit collar 4, and the outer sides of the top connecting seat 2 and the bottom connecting seat 3 are provided with a bearing seat 5, and the outer side of the bearing seat 5 is surrounded by an annular gap 6, and the bottom of the bearing seat 5 has two Each end is provided with a bottom joint seat 7, and both ends of the top of the bearing seat 5 are provided with a top joint seat 8.

[0024] Further, the top connection seat 2, the bottom connection seat 3, the limit collar 4 and the bearing seat 5 are integrally arranged, and the bottom joint seat 7 and the top joint seat 8 are integrally arrang...

Embodiment 2

[0029] Further, the inner walls of the top connecting seat 2, the bottom connecting seat 3 and the limiting collar 4 are all provided with connecting threads, and the limiting collar 4 is arranged around the outer side of the bottom connecting seat 3 and is arranged on the two bottoms. Between the joint seat 7.

[0030] Further, the annular notch 6 is arranged around the outer side of the bearing seat 5, and the bearing seat 5 is made of alloy material.

[0031] Beneficial effects of this embodiment: installation is carried out through the top connecting seat 2 and the bottom connecting seat 3, and after the installation is completed, the welding connection is performed again through the outer bottom joint seat 7 to ensure that the internal position is stable and can be connected by the outer socket The ring is clamped inside the annular notch 6, and is double stabilized from the inside and the outside to ensure overall stability.

Embodiment 3

[0033] Further, the number of the bottom joint seats 7 is set to two, and the two bottom joint seats 7 are fixedly connected without chamfering. The angle in the horizontal direction is 9°.

[0034] Beneficial effects of this embodiment: the angle between the bottom joint seat 7 and the joint body 1 in the horizontal direction is set to 9°, which can ensure that there is no gap or a very small gap between the joints during connection, and the angle of the joint is different from that of the joint body 1. Surface contact, the basic principle of resistance welding will not be violated during the welding process, that is, line contact between the welded parts must be achieved, which ensures high welding strength, and can not only eliminate the welding gap, but also ensure the best welding strength, and the structure is simple , easy to realize, just change the processing program on the original CNC processing equipment, without changing the shape and weight of the original blank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com