High-voltage bus induction power taking device and method

A technology of inductive power acquisition and high-voltage bus, which is applied in the direction of circuit devices, battery circuit devices, emergency protection circuit devices, etc., can solve the problems of saturation heating, affecting practicability, unfavorable installation of fully enclosed ring structure, etc., to achieve suppression of saturation, easy to install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

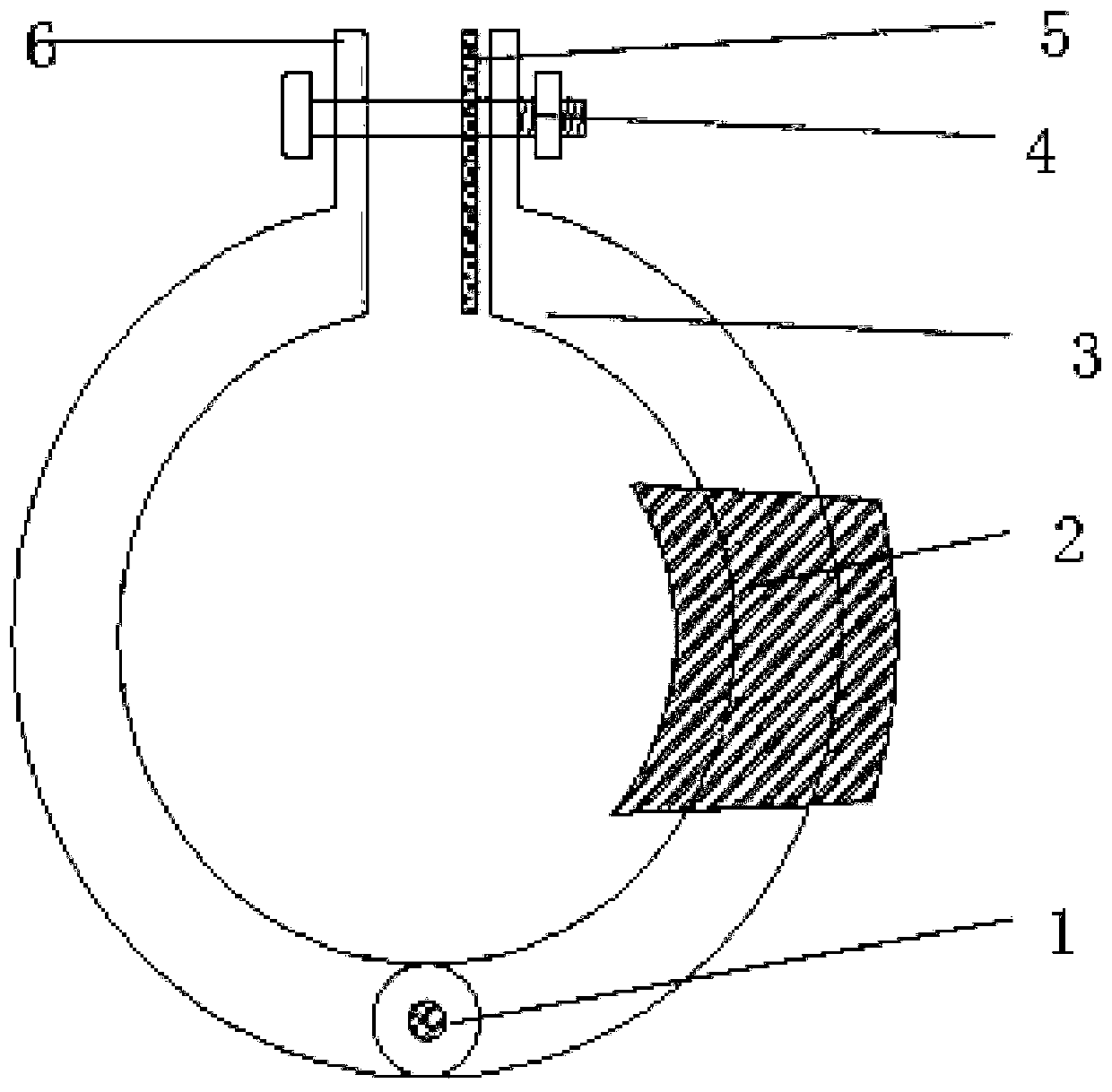

[0022] Embodiment 1: as Figure 1 to Figure 5 As shown, a high-voltage bus induction power-taking device and method, including an induction power-taking device and a power processing device; it is characterized in that the induction power-taking device is composed of two C-shaped magnetic cores, and the bottom of the two C-shaped magnetic cores Connected by the rotating shaft, there are protrusions on the upper part of the two C-shaped magnetic cores, and there is a hole in the middle of the protrusions, and the fastening bolts pass through the holes to fix the magnetic cores. There is a coil wound in the middle of either side of the C-shaped magnetic core; when installing, the interface can be opened, inserted into the busbar, and then fastened to the busbar by bolts.

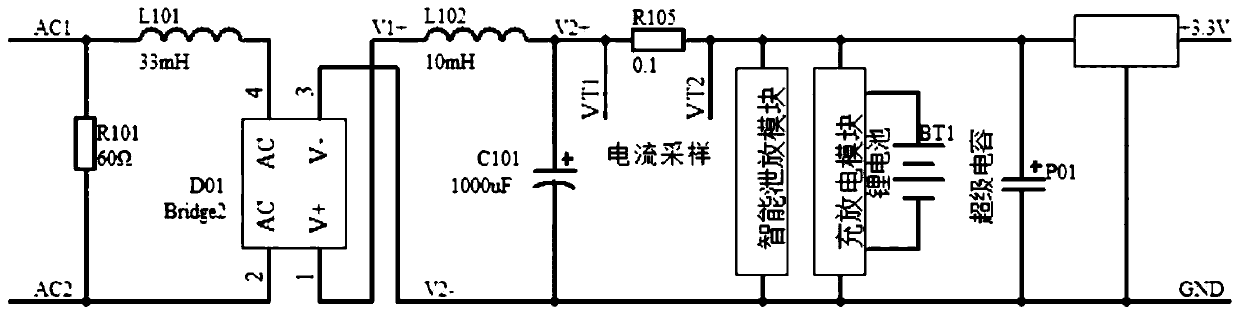

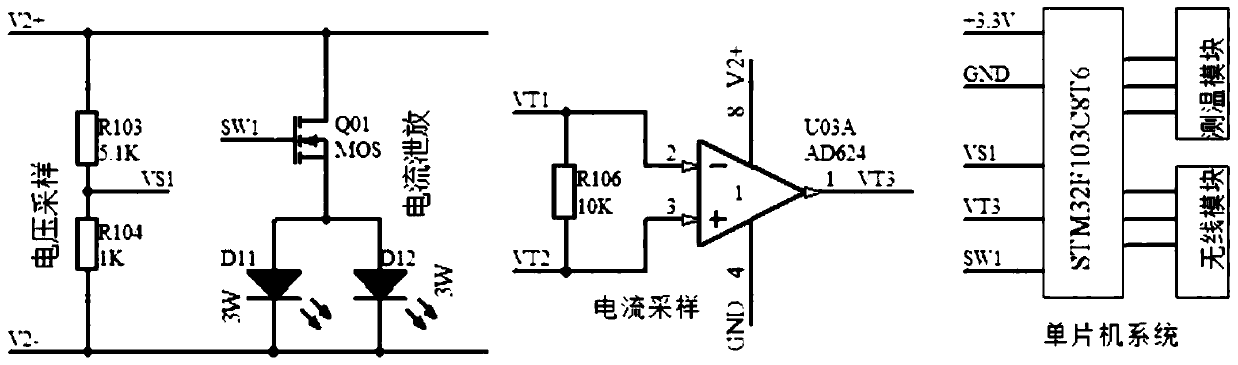

[0023] The power processing device is composed of a filter circuit, a rectifier circuit, a low-pass filter circuit, an intelligent energy discharge module, a voltage stabilizing circuit, a lithium battery char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com