Single-phase two-tube five-level rectifier based on hybrid H bridge

A five-level rectifier technology, applied in the direction of irreversible AC power input conversion to DC power output, electrical components, high-efficiency power electronic conversion, etc., can solve the problems of low output voltage level, large number of switching tubes, high harmonic content, etc. , to achieve reliable power output, improve work reliability, and realize the effect of power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

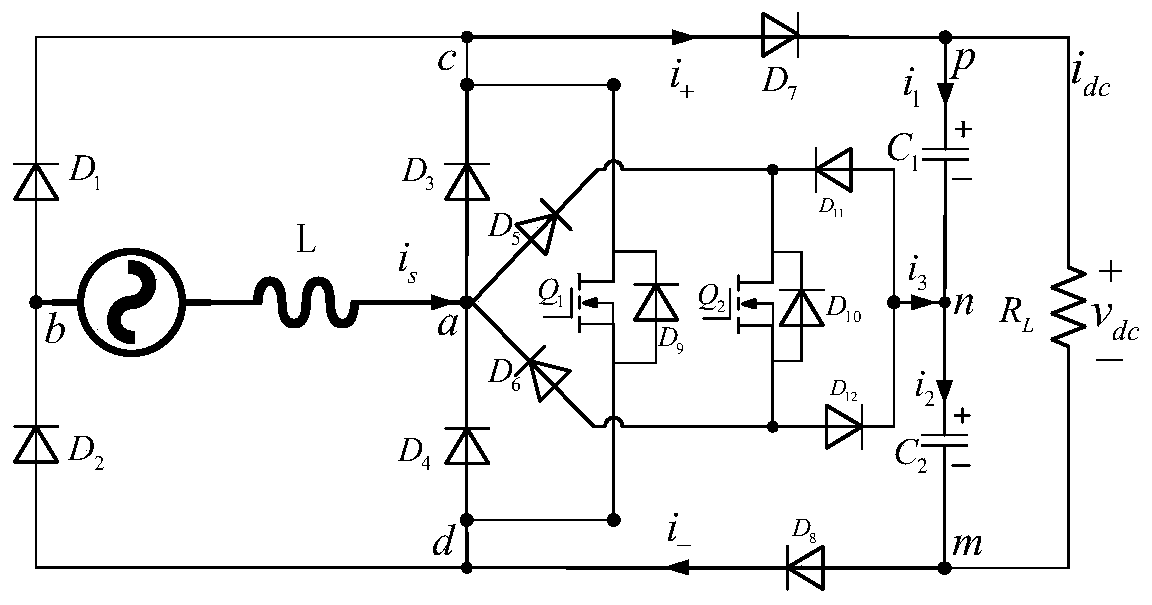

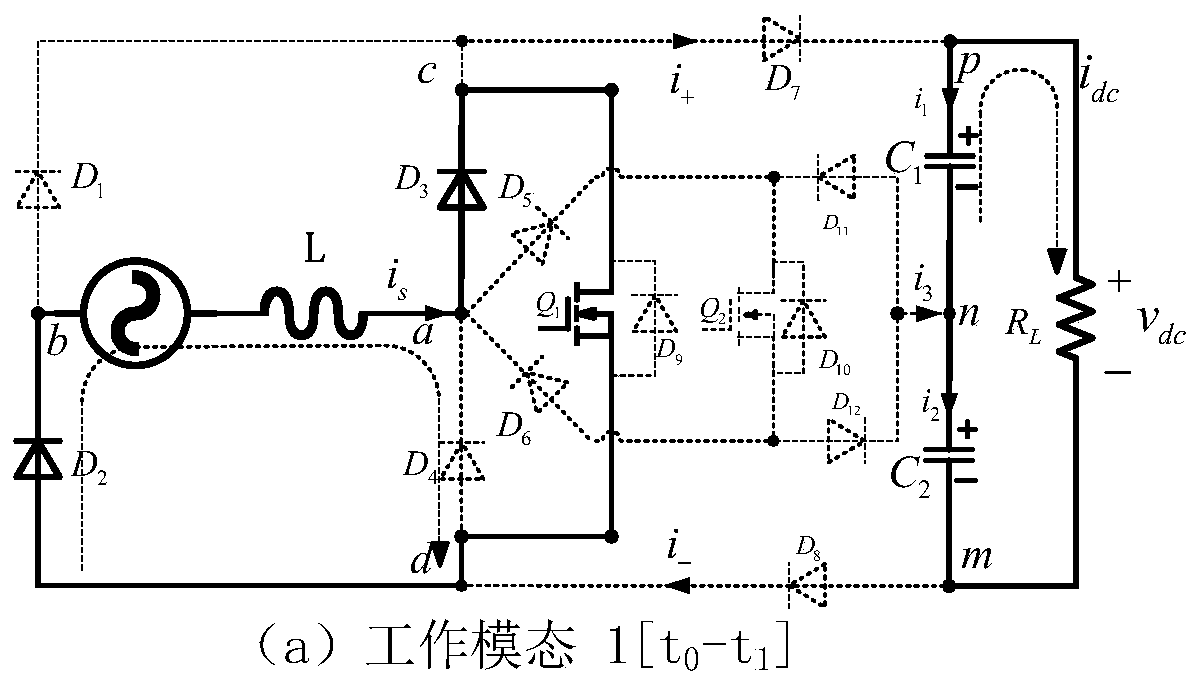

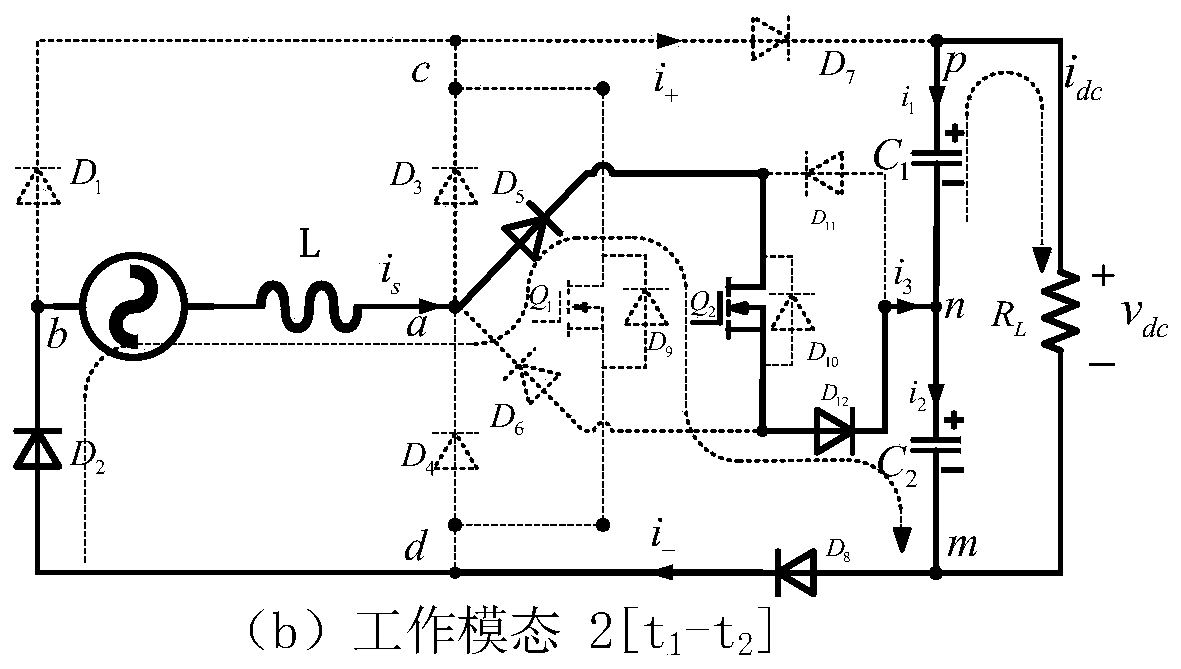

[0049] Such as figure 1 As shown, a single-phase two-tube five-level rectifier based on a hybrid H-bridge, including an inductor L and a switch tube Q 1 , switch tube Q 2 , Diode D 1 ~D 12 , capacitance C 1 , capacitance C 2 . Diode D is connected to one side of the AC power supply Vs 1 anode, diode D 2 a cathode, the connection node forming terminal b;

[0050] The other side of the AC power supply Vs is connected to one end of the inductor L, and the other end of the inductor L is connected to the diode D 3 anode, diode D 4 cathode, diode D 5 anode, diode D 6 Cathode; the other end of the inductor L and the diode D 3 、D 4 、D 5 、D 6 The connected nodes of constitute the endpoint a;

[0051] Switch tube Q 1 The drains are connected to the diode D 1 cathode, diode D 3 cathode, diode D 7 anode; switch tube Q 1 Drain and Diode D 1 、D 3 、D 7 The connected nodes of constitute the endpoint c;

[0052] Switch tube Q 1 The source is connected to the diode D r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com