Polypropylene composition

A polypropylene composition and composition technology, applied in the direction of flexible coverings, synthetic resin layered products, packaging, etc., can solve the problems of not being able to provide low sealing initiation temperature optical properties, high SIT, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] Detailed descriptions of the preparation of catalysts are disclosed in WO 2012 / 007430, EP 2610271 , EP 261027 and EP2610272.

[0105] Alternatively, Ziegler-Natta catalysts are modified by the so-called BNT technique in a prepolymerization step to introduce polymeric nucleating agents.

[0106] Preferably, such polymeric nucleating agents are vinyl polymers, such as vinyl polymers derived from monomers of the formula:

[0107] CH 2 =CH-CHR 1 R 2

[0108] Among them, R 1 and R 2 Together with the carbon atoms to which they are attached, an optionally substituted saturated or unsaturated ring or aromatic ring or fused ring system is formed; wherein said ring or fused ring moiety comprises 4 to 20 carbon atoms; preferably, said The ring or condensed ring part is 5 to 12 membered saturated or unsaturated ring or aromatic ring or condensed ring system, or independently represents straight or branched chain C 4 -C 30 Alkanes, C 4 -C 20 cycloalkane or C 4 -C 20 aro...

Embodiment

[0316] Component (a):

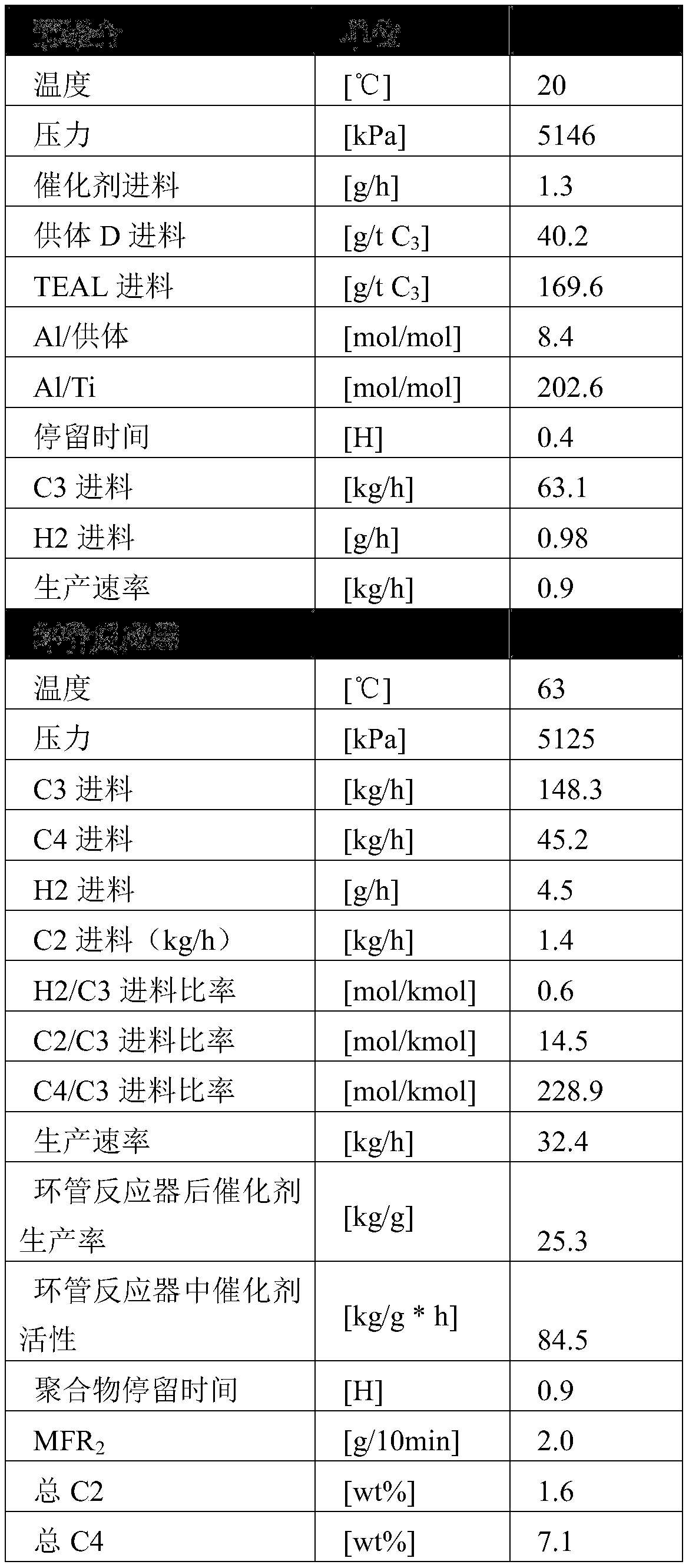

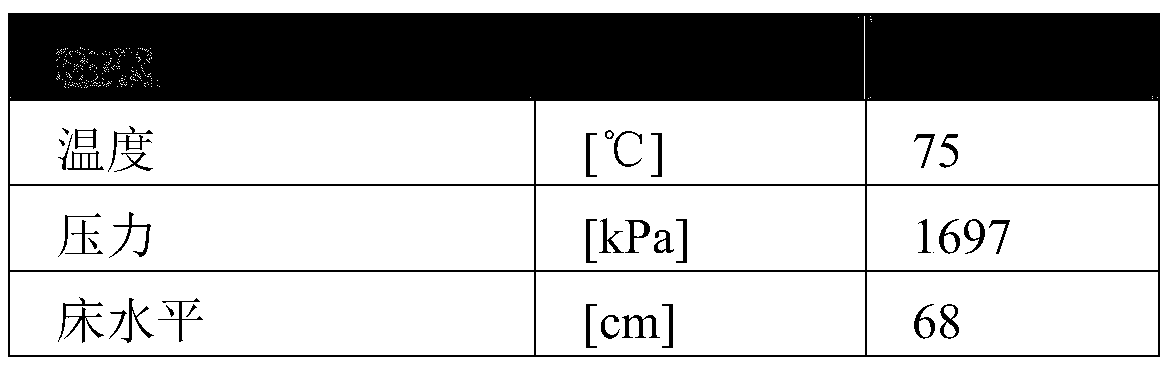

[0317] Propylene-ethylene-1 for inventive examples (IE) and comparative examples (CE) were prepared in the slurry loop reactor of the Borstar PP pilot plant (only upstream prepolymerization step) -Butene terpolymer. A gas phase reactor (GPR) was used as a high pressure (HP) flasher with a pressure of 1700 kPa and a bed level of 70 cm. A rapid flow of 35 kg / h propylene was used to keep the direct feed line open between the loop reactor and the GPR. The catalyst used was Avant ZN180M supplied by LyondelBasell. The cocatalyst is TEAL and the external donor is donor D. Table 1 shows the polymerization data for propylene-ethylene-1-butene terpolymers.

[0318] Table 1

[0319]

[0320]

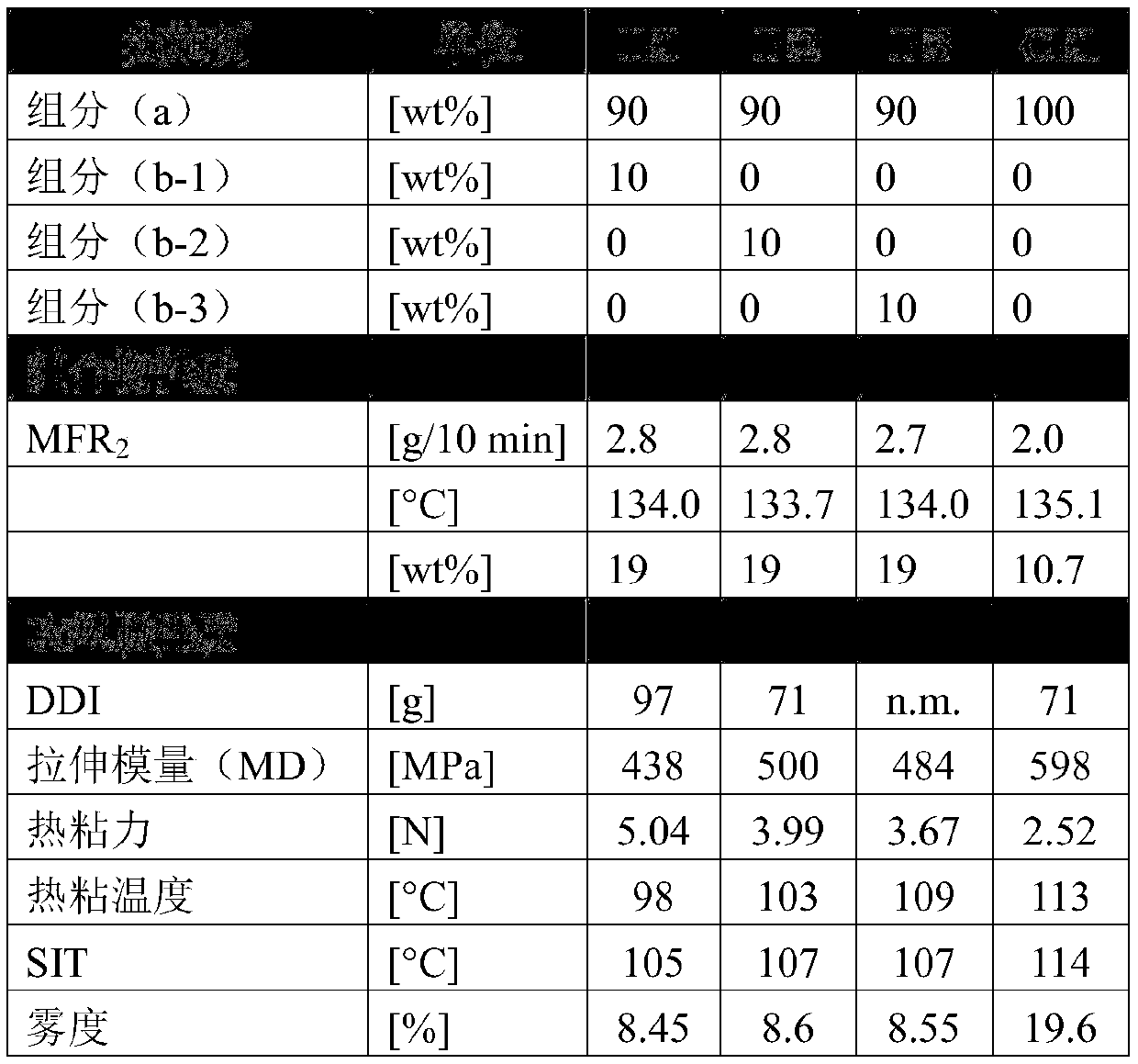

[0321] On a co-rotating twin-screw extruder of the Coperion ZSK 40 type (screw diameter 40 mm, L / D ratio 38), using a high-intensity mixing screw configuration with two sets of kneading blocks, the terpolymer thus obtained was mixed with the following The additives...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com