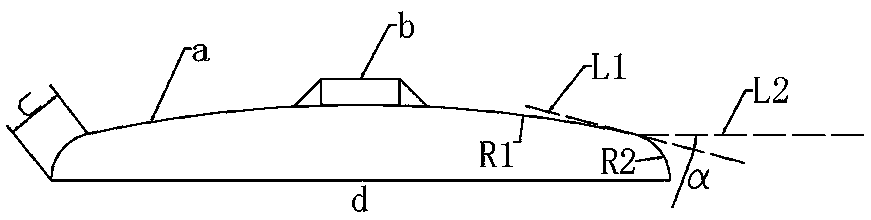

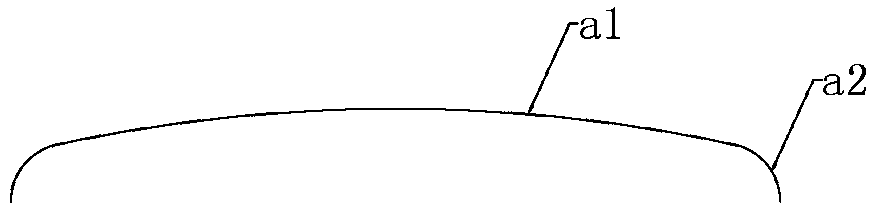

Ultra-large-specification thin porcelain plate with antibacterial function, and preparation method thereof

A super-large and thin technology, which is applied in the field of architectural ceramics, can solve the problems of insufficient decorative effects, easy damage, and limited decoration methods, so as to improve the recombination of internal electrons and holes, improve photocatalytic performance, and solve easy reunion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

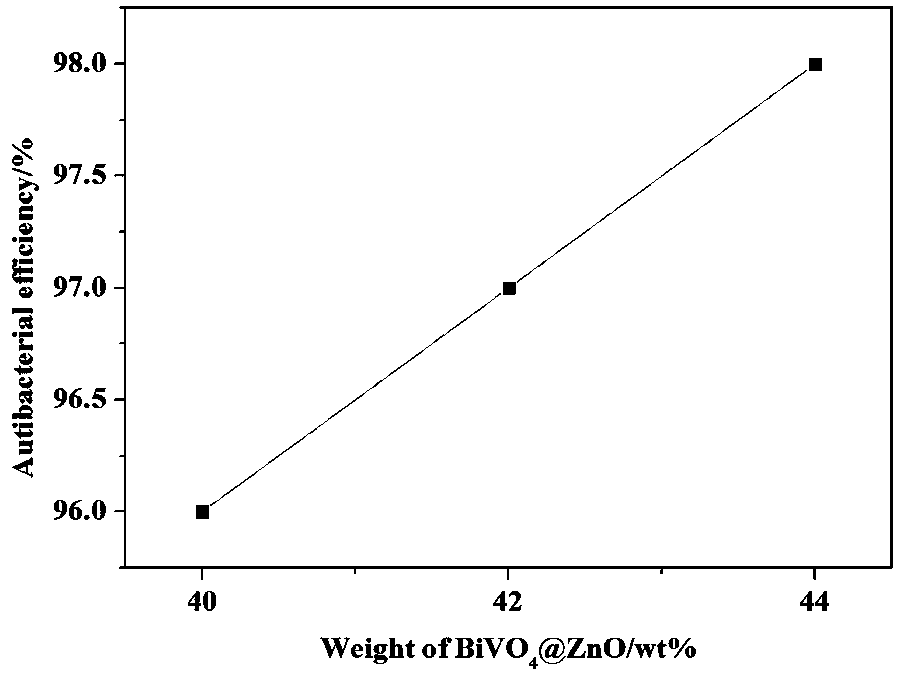

Embodiment 1

[0077] A, according to conventional method, prepare super large-scale thin-type porcelain plate green body powder, for subsequent use;

[0078] B, prepare super-large-scale thin porcelain plate base glaze according to conventional methods, prepare super-large-scale thin porcelain plate with anti-slip function polishing glaze according to conventional methods, and the chemical composition of described polishing glaze in weight percentage is SiO 2 : 45%, Al 2 o 3 : 28%, CaO: 4%, MgO: 2%, K 2 O: 3%, Na 2 O: 4%, ZnO: 1%, BaO: 11%, ZrO 2 : 2%, introduce high-fire frit into the polishing glaze, set aside;

[0079] C. Preparation of composite antibacterial functional materials: composite antibacterial functional materials include nanocomposite antibacterial powders, liquid dispersants and suspension stabilizers, and the preparation method of the nanocomposite antibacterial powders is as follows:

[0080] a) Prepare a 0.25mol / L bismuth nitrate solution, and add a certain amount o...

Embodiment 2

[0103] A, according to conventional method, prepare super large-scale thin-type porcelain plate green body powder, for subsequent use;

[0104] B, prepare super-large-scale thin porcelain plate base glaze according to conventional methods, prepare super-large-scale thin porcelain plate with anti-slip function polishing glaze according to conventional methods, and the chemical composition of described polishing glaze in weight percentage is SiO 2 : 50%, Al 2 o 3 : 21%, CaO: 7%, MgO: 2%, K 2 O: 2%, Na 2 O: 1%, ZnO: 2%, BaO: 13%, ZrO 2 : 2%, introduce high-fire frit into the polishing glaze, set aside;

[0105] C. Preparation of composite antibacterial functional materials: composite antibacterial functional materials include nanocomposite antibacterial powders, liquid dispersants and suspension stabilizers, and the preparation method of the nanocomposite antibacterial powders is as follows:

[0106] a) Prepare a 0.20mol / L bismuth nitrate solution, and add a certain amount o...

Embodiment 3

[0129] A, according to conventional method, prepare super large-scale thin-type porcelain plate green body powder, for subsequent use;

[0130] B, prepare super-large-scale thin porcelain plate base glaze according to conventional methods, prepare super-large-scale thin porcelain plate with anti-slip function polishing glaze according to conventional methods, and the chemical composition of described polishing glaze in weight percentage is SiO 2 : 45%, Al 2 o 3 : 27%, CaO: 4%, MgO: 2%, K 2 O: 3%, Na 2 O: 4%, ZnO: 1%, BaO: 11%, ZrO 2 : 3%, the corundum material is introduced into the polishing glaze, and it is set aside;

[0131] C. Preparation of composite antibacterial functional materials: composite antibacterial functional materials include nanocomposite antibacterial powders, liquid dispersants and suspension stabilizers, and the preparation method of the nanocomposite antibacterial powders is as follows:

[0132] a) Prepare a 0.25mol / L bismuth nitrate solution, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com