A kind of natural latex stabilizer and its application

A natural rubber latex and stabilizer technology, applied in the field of natural rubber latex stabilizers, can solve the problems of environmental pollution, strong irritation, and easy volatilization of ammonia water, and achieve the effects of improving stability, ensuring convenience, and improving mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

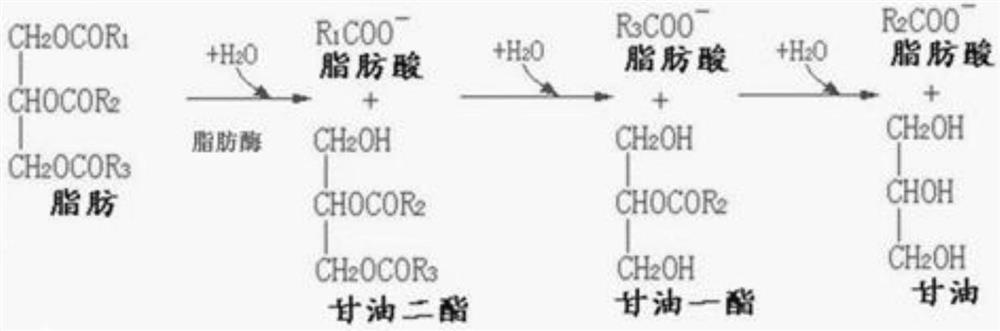

Method used

Image

Examples

Embodiment 1

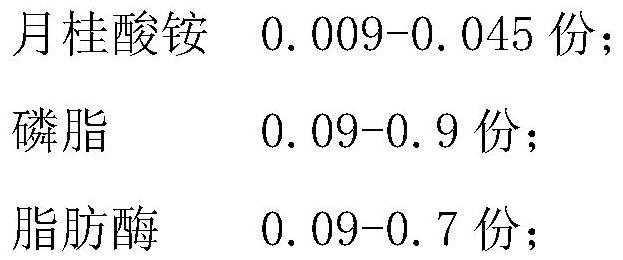

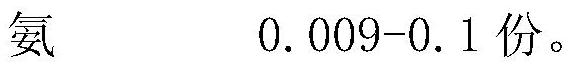

[0040] (a) Weighing 10 parts of lipase and adding it to 90 parts of 0.1mol / L phosphate buffer (pH=7.2), stirring and grinding to obtain a uniformly dispersed lipase suspension, ready for use;

[0041] (b) Weigh 20 parts of water-soluble phospholipids, dissolve in 100 parts of ammonia water with a mass fraction of 25%, stir at room temperature for 4 hours, and prepare a uniform emulsion for use;

[0042] (c) get the concentrated natural rubber latex that is 60% of the total solid mass fraction collected at the outlet of the high-speed centrifuge after centrifugal concentration processing, and measure the mass fraction of its ammoniacal liquor to be 0.18%, and the mechanical stability is 40s.

[0043] Get 10000 parts of concentrated natural rubber latex, add 4.5 parts of ammonium laurate, the lipase suspension described in step (a) successively under stirring, add the phospholipid emulsion described in step (b) after stirring 1h, stir and mix, Mix well for 1 hour and start the f...

Embodiment 2

[0045] (a) Weigh 20 parts of lipase and add it to 100 parts of 0.1mol / L phosphate buffer (pH=7.0), stir and grind to obtain a lipase suspension with a mass fraction of 16.7%, which is ready for use;

[0046] (b) Weigh 30 parts of water-soluble phospholipids, dissolve in 170 parts of ammonia water with a mass fraction of 25%, stir at room temperature for 4 hours, and prepare a uniform emulsified solution for use;

[0047] (c) get the concentrated natural rubber latex that is 60% of the total solid mass fraction collected at the outlet of the high-speed centrifuge after centrifugal concentration processing, and measure the mass fraction of its ammoniacal liquor to be 0.18%, and the mechanical stability is 40s.

[0048] Get 10000 parts of concentrated natural rubber latex, add 40 parts of ammonium laurate, the lipase suspension described in step (a) successively under stirring, add the phospholipid emulsion described in step (b) after stirring 1h, stir and mix, Mix well for 1 hou...

Embodiment 3

[0050] (a) 40 parts of lipase were weighed and added to 160 parts of 0.1mol / L phosphate buffer (pH=7.6), stirred and ground to obtain a lipase suspension with a mass fraction of 20%, which was then used;

[0051] (b) Weigh 50 parts of water-soluble phospholipids, dissolve in 200 parts of ammonia water with a mass fraction of 25%, stir at room temperature for 4 hours, and prepare a uniform emulsion for use;

[0052] (c) get the concentrated natural rubber latex that is 60% of the total solid mass fraction collected at the outlet of the high-speed centrifuge after centrifugal concentration processing, and measure the mass fraction of its ammoniacal liquor to be 0.15%, and the mechanical stability is 38s.

[0053] Get 10000 parts of concentrated natural rubber latex, add 50 parts of ammonium laurate, the lipase suspension described in step (a) successively under stirring, add the phospholipid emulsion described in step (b) after stirring for 1.5h, stir and mix evenly , start the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com