Leaked oil collecting and classifying device

A sorting device and oil technology, applied in the direction of liquid separation, separation method, general water supply saving, etc., can solve the problems of marine pollution, high energy consumption, high cost, etc., to improve the recovery of oil bodies, improve the separation effect, and reduce the cost of cleaning pollution low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

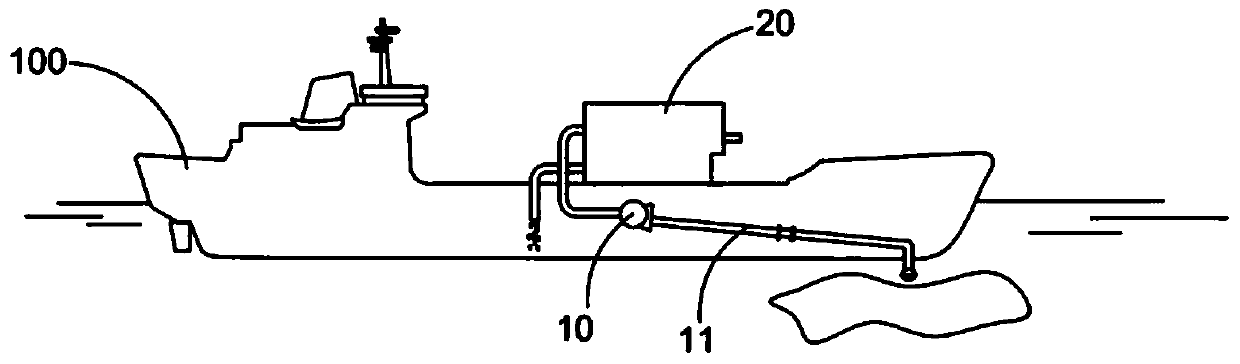

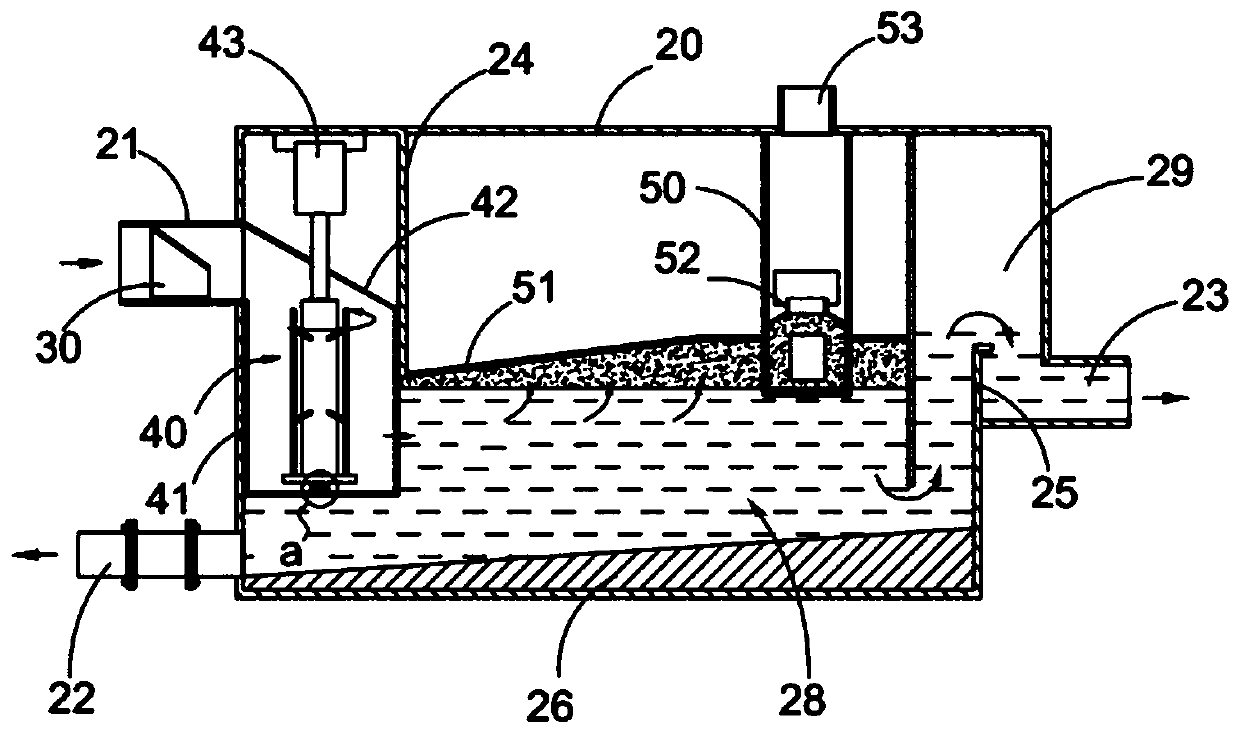

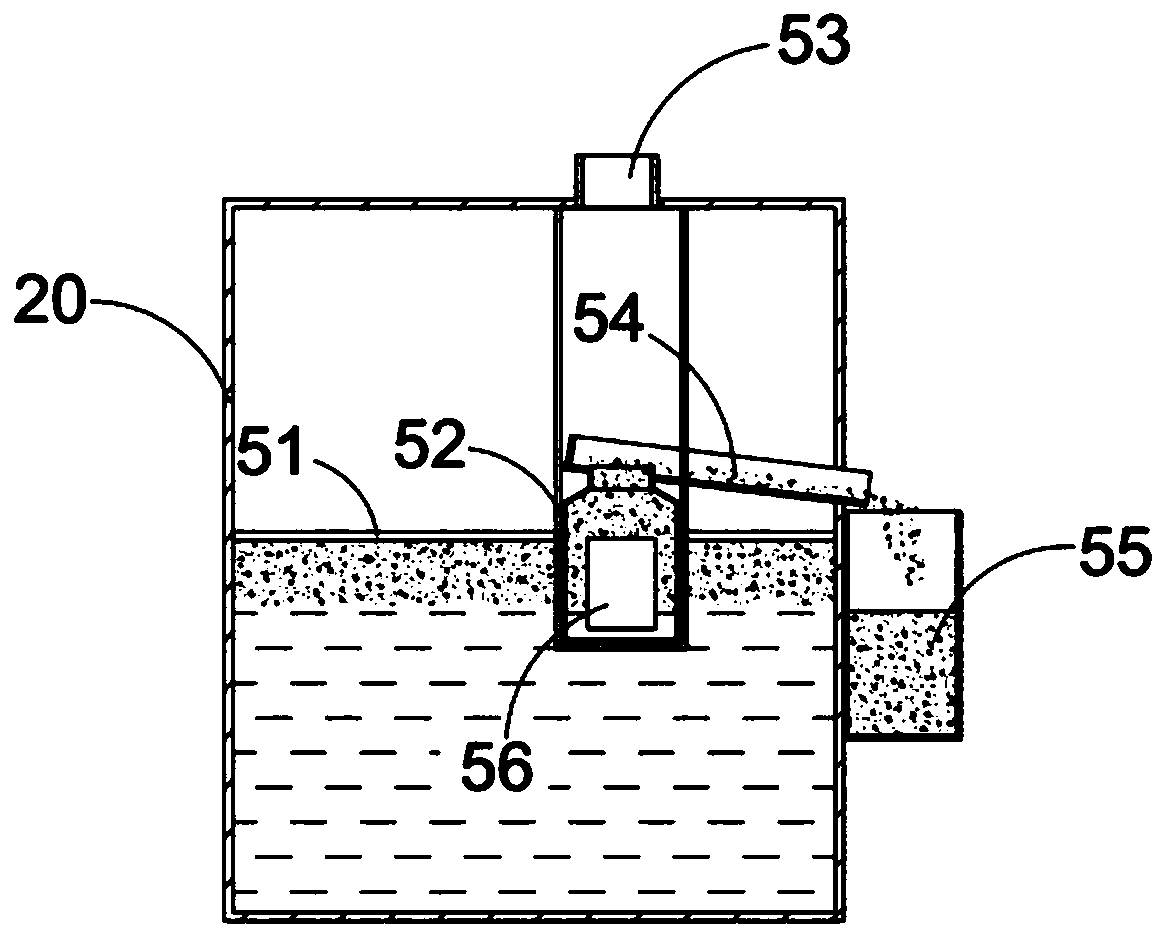

[0031] see figure 1 , 2 As shown in , 9, a leaking oil collection and classification device includes: a separation processing assembly 20, which is arranged on the water surface moving assembly 100, and the separation processing assembly 20 extracts the water surface oil through the external liquid suction power part 10 and the liquid transfer pipe 11 The liquid mixture, the separation processing assembly 20 includes a processing box, and one side of the processing box is provided with a mixed liquid inlet pipe 21 connected to the liquid transfer pipe 11, and at least two inlet guide sleeves 30 are arranged in the mixed liquid inlet pipe 21 to feed The two ports of the flow guide sleeve 30 are circular and have different sizes. The small end of the aperture is set to the end of the outlet direction of the oil-water mixture, and the end of the large aperture is set to the end of the flow direction of the oil-water mixture. 21 connected to the first oil-water separation chamber...

Embodiment 2

[0043] After an oil spill accident occurs, move the component 100 through the water surface, such as the hull loading the separation treatment component 20, and quickly sail to the oil spill sea area or water area to recover the leaked oil, and use the liquid suction power part 10, such as a high-power water pump to cooperate with the liquid transfer pipe 11 And the installed liquid suction sleeve 60 to extract the oil-water mixture on the surface of the water into the separation treatment assembly 20. After the oil-water mixture enters the separation treatment assembly 20, it goes through the first oil-water separation chamber for centrifugal treatment and the second oil-water separation. Chamber sedimentation treatment The separated crude oil is discharged to the oil collection container 55 through the oil discharge assembly 50 for unified collection, and the separated water body passes through the overflow plate body 25 and then is discharged from the separation treatment ass...

Embodiment 3

[0046] Spilled oil simulated collection test:

[0047] In order to avoid the test from polluting the environment, the test design is carried out in a water tank for simulation tests. The size of the water tank is: length x width x height = 3m x 1.5m x 1m; and the water tank is made of transparent glass for easy observation. The temperature of the water in the tank 23±1℃, water density ρ ω 986kg / m 3 , oil density ρ o 892kg / m 3 , the design leakage oil flow rate is 1m 3 / h.

[0048] Design four groups of experimental groups to carry out the oil collection test, which are experimental group 1, experimental group 2, experimental group 3, and experimental group 4. The water content of the oil collected by each experimental group is detected respectively, and the detection method is selected - the determination of the water content of crude oil Hugh coulometric titration (GB / T11146-2009).

[0049] Experimental group 1 selects the device of embodiment 1 of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com