Cast-in-place bored energy pile with novel pipe layout mode and construction method thereof

A technology of drilling perfusion and construction method, applied in the field of civil engineering, can solve the problems of unguaranteed quality, high cost, unstable quality, etc., and achieve the effects of reducing pile deformation, strengthening protection, and being widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

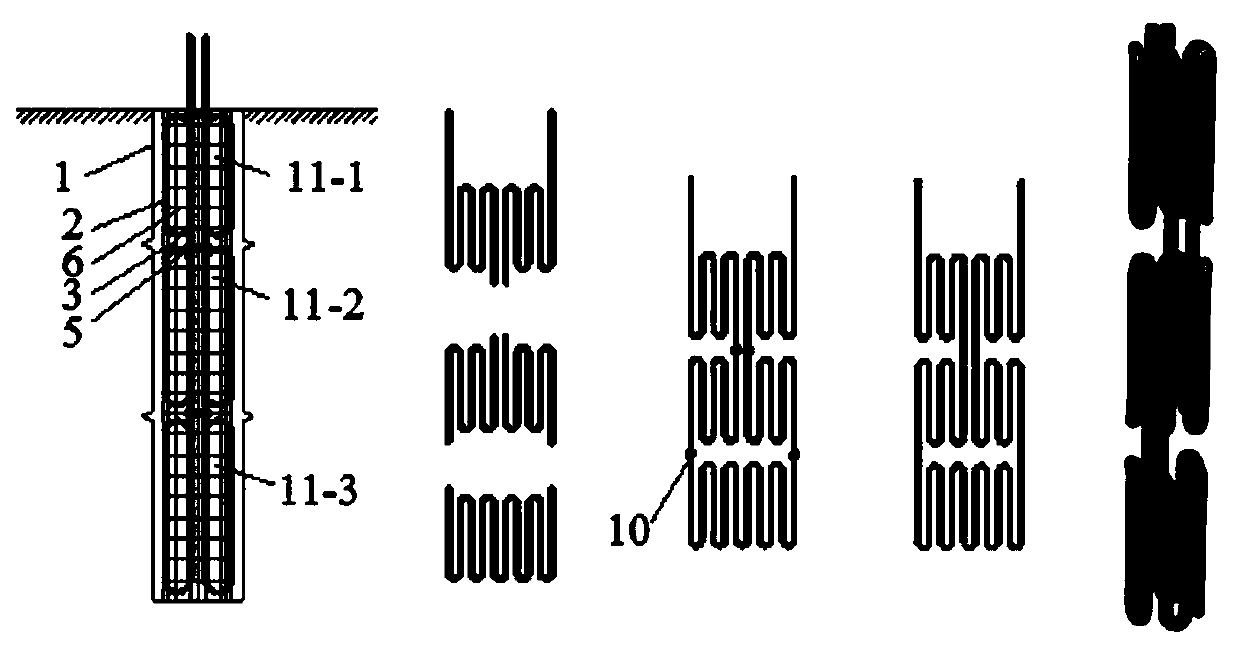

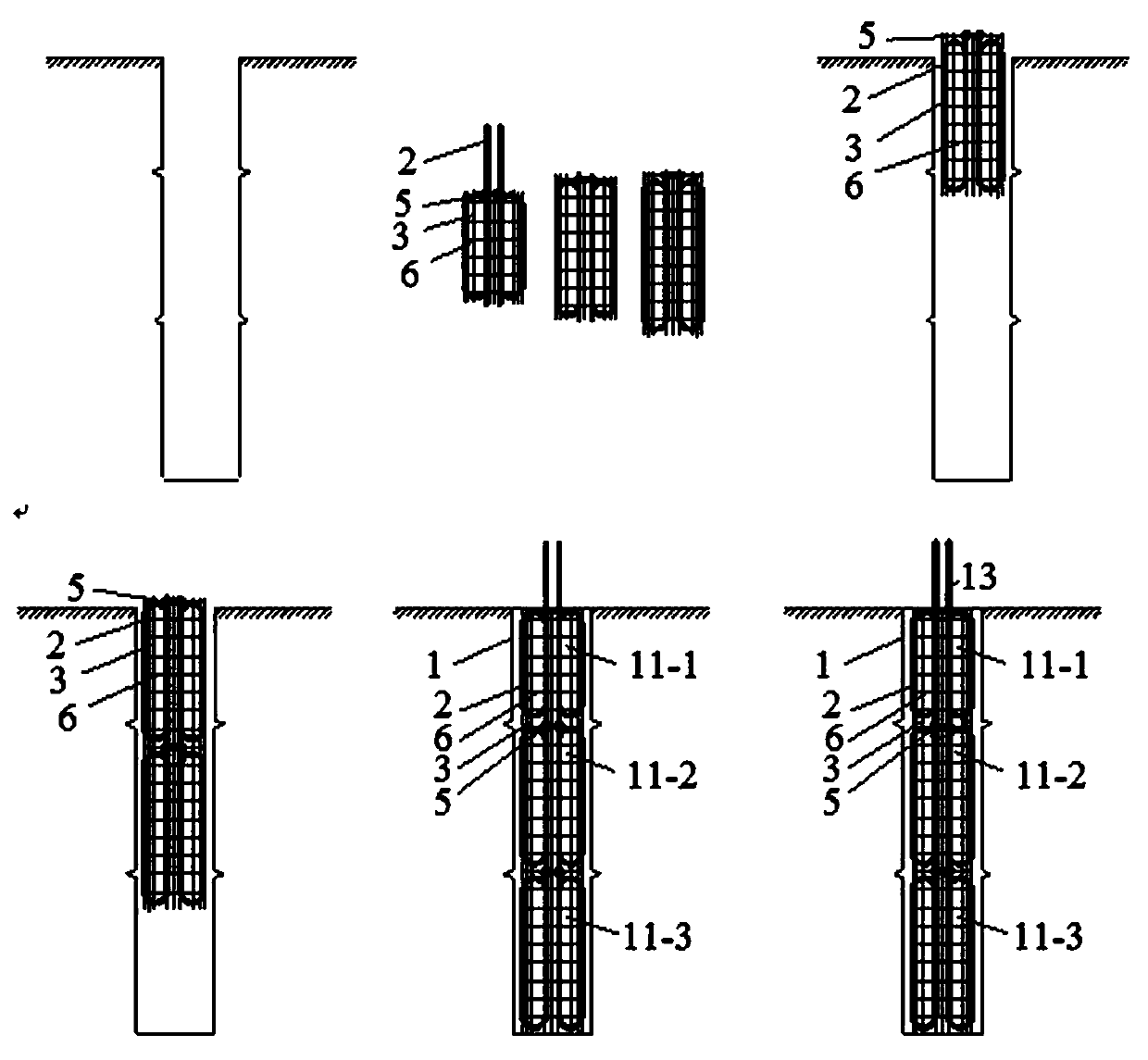

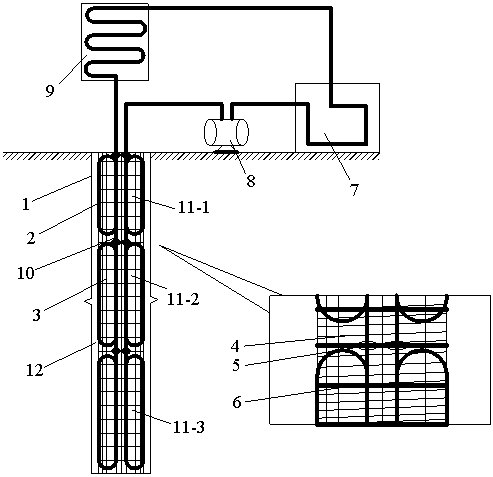

[0028] Such as figure 1 As shown, a new type of bored perfusion energy pile in the form of pipe layout includes a perfusion pile 1, the diameter of the perfusion pile is 0.8m~2.5m, the pile length is greater than 20m, and the heat transfer tube 2 arranged in the perfusion pile 1 The water pump 8 connected to the inlet of the heat transfer pipe 2, and the heat collector 7 connected to the outlet of the heat transfer pipe 2, both the water pump 8 and the heat collector 7 are connected to the heat exchange structure 9, and the cast-in-situ pile 1 is composed of a plurality of steel bars The cage 11 is welded in sections, and each reinforcement cage 11 is composed of top reinforcement cage 11-1, bottom reinforcement cage 11-2 and middle reinforcement cage 11-3. The top and bottom of each reinforcement cage 11 are welded There is a steel bar hoop 5, the steel bar hoop 5 is semicircular, the two ends of the steel bar hoop 5 are respectively welded on the reinforcing stirrups 6 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com