Centrifugal pump fault diagnosis method and system

A fault diagnosis, centrifugal pump technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve the problems of unrepresentative, large and complex sample extraction, and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

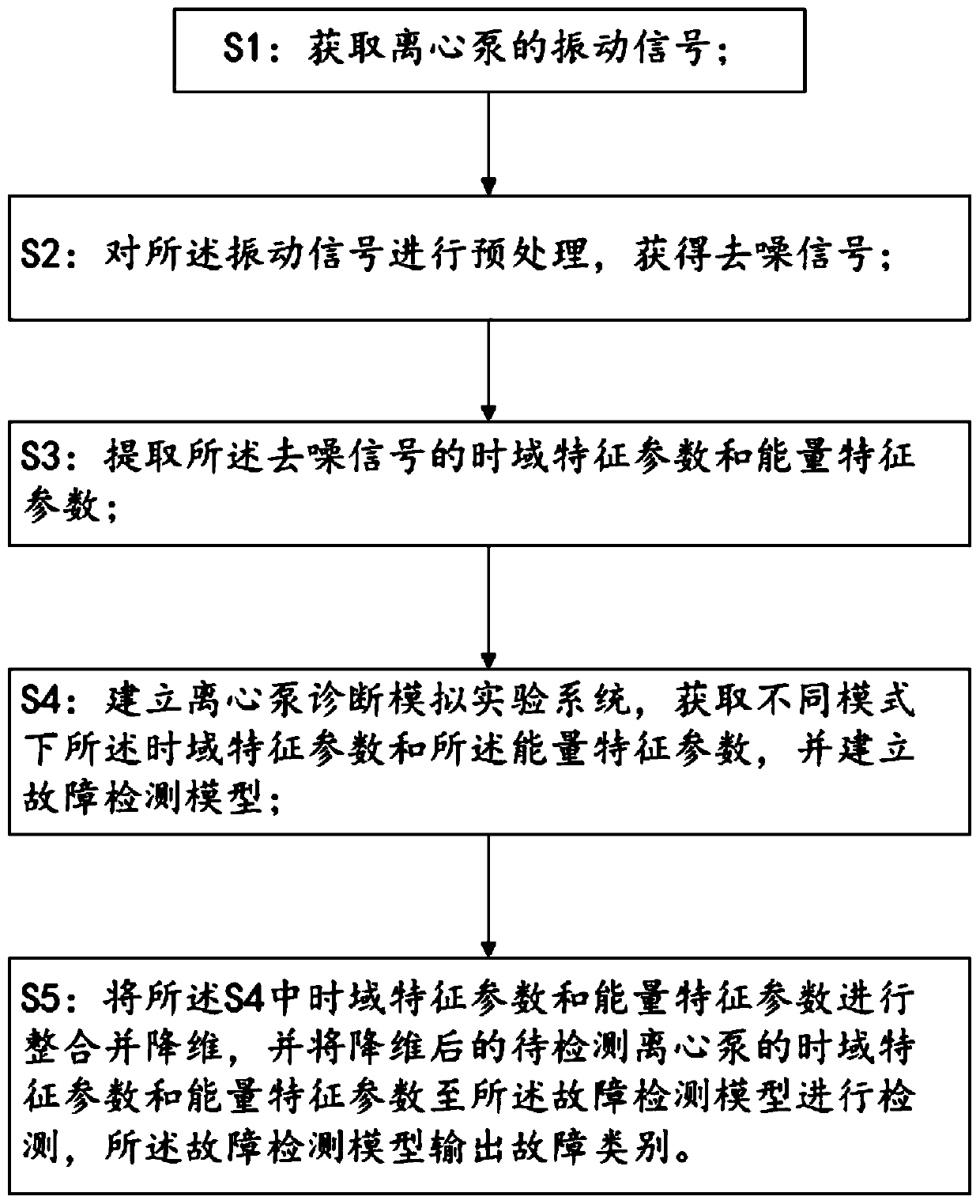

[0084] refer to figure 1 , a centrifugal pump fault diagnosis method, comprising the following steps:

[0085] S1: Obtain the vibration signal of the centrifugal pump;

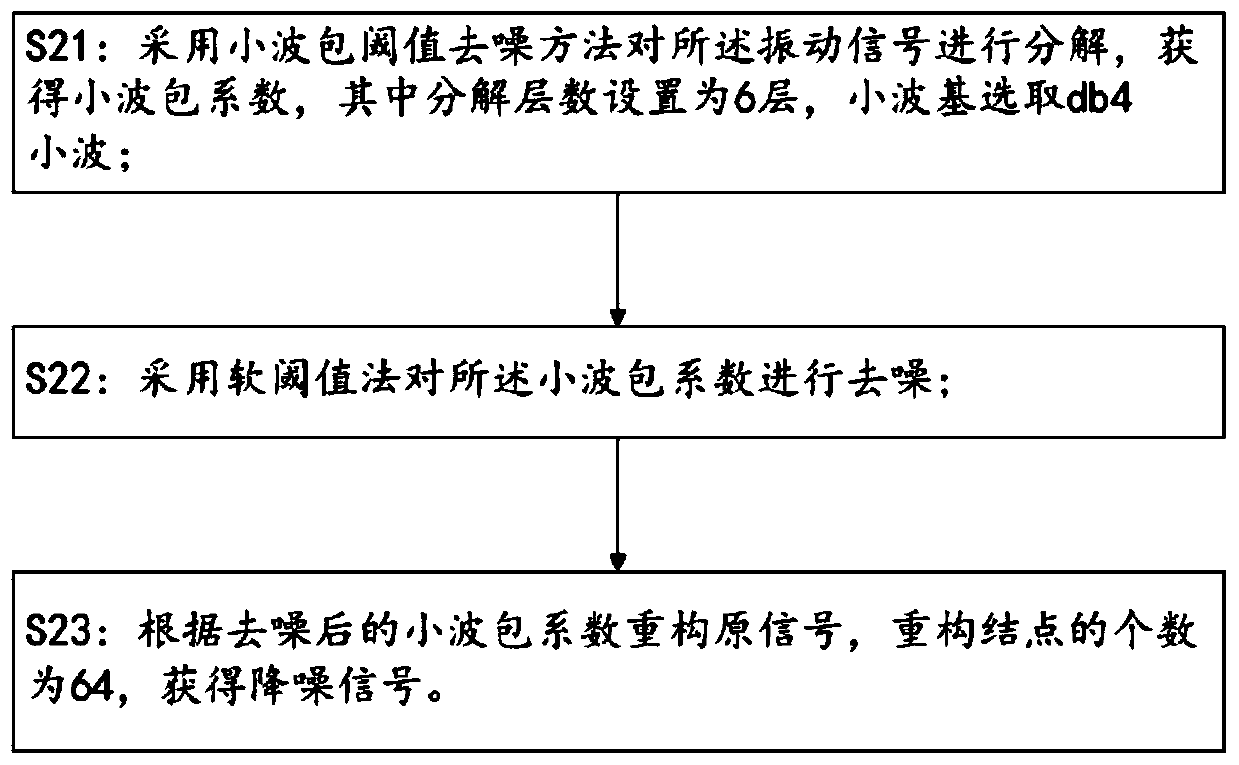

[0086] S2: Preprocessing the vibration signal to obtain a denoising signal;

[0087] S3: extracting time-domain characteristic parameters and energy characteristic parameters of the denoising signal;

[0088] S4: Establish a centrifugal pump diagnostic simulation experiment system, obtain time-domain characteristic parameters and energy characteristic parameters in different modes, and establish a fault detection model;

[0089] S5: Integrate the time-domain characteristic parameters and energy characteristic parameters in S4 and reduce the dimension, and send the time-domain characteristic parameters and energy characteristic parameters of the centrifugal pump to be detected after dimensionality reduction to the fault detection model for detection, and the fault detection model outputs faults category.

...

Embodiment 2

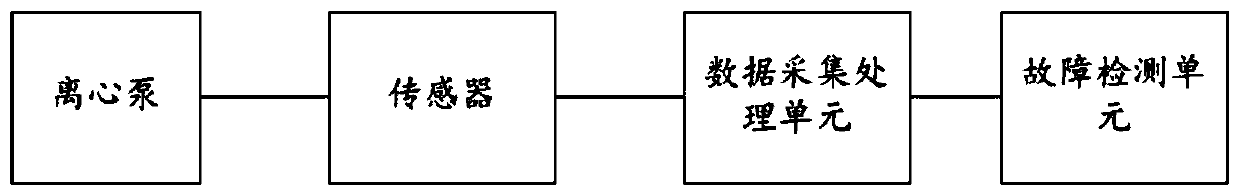

[0161] On the basis of embodiment 1, a centrifugal pump fault diagnosis system includes a centrifugal pump, a sensor, a data acquisition processing unit and a fault detection unit;

[0162] The impeller is installed in the centrifugal pump, the sensor is installed on the shaft of the centrifugal pump, and is electrically connected with the data acquisition and processing unit, and the sensor is used to collect the vibration signals of the centrifugal pump in different modes and transmit them to the data acquisition and processing unit;

[0163] The output end of the data acquisition and processing unit is electrically connected to the fault detection unit, and the data acquisition and processing unit is used to extract the time-domain characteristic parameters and energy characteristic parameters of the vibration signal and transmit the time-domain characteristic parameters and energy characteristic parameters to the fault detection unit after dimensionality reduction ;

[016...

Embodiment 3

[0167] On the basis of embodiments 1 and 2, in S46, the fault detection model can also be established using a BP neural network, and the specific process is as follows:

[0168] S463: Determine the number of nodes in each layer of the BP neural network;

[0169] S464: select a training function;

[0170] S465: Input the time-domain feature parameters and energy feature parameters in the four modes into the training function for training, and use the trained model as a fault detection model.

[0171] refer to Figure 4 , BP neural network includes input layer, output layer and hidden layer.

[0172] Wherein, the number of neuron nodes in the input layer is the same as the number of observations of the input samples. In this embodiment, the number of input nodes is 5, corresponding to 4 fault states of the centrifugal pump, and the number of neuron nodes in the output layer is set to 4.

[0173] The ability of BP neural network to process data increases with the number of hid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com