Inner and outer diameter measuring device for thin-wall bearing ring

A technology of thin-walled bearings and measuring devices, which is applied in the direction of electromagnetic measuring devices, electric/magnetic diameter measurement, etc., and can solve problems such as large error in measurement results, large measuring force of torsion spring meters, and harsh use environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

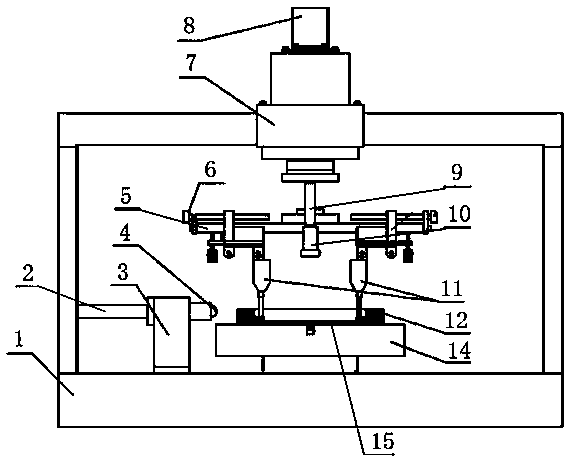

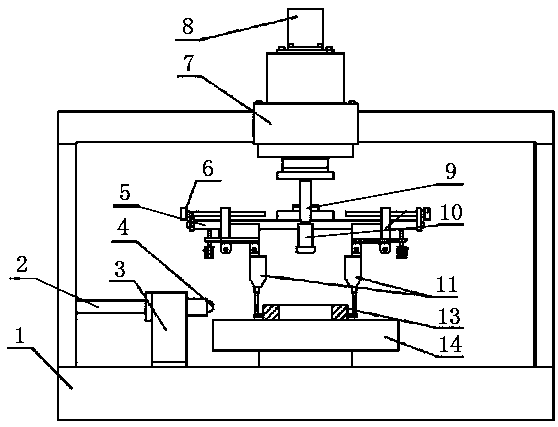

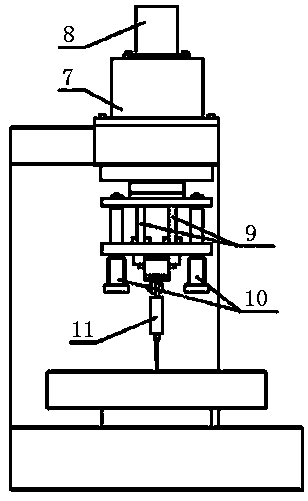

[0020] Referring to the accompanying drawings, the specific implementation is as follows:

[0021] A device for measuring inner and outer diameters of thin-walled bearing rings, comprising a measuring assembly with two displacement sensors 11, and a calibration assembly for relative positioning of the displacement sensors 11 and the thin-walled bearing 18, the measuring assembly It also includes a workbench 14 and a motor 8 arranged on the base 1. The workbench 14 is provided with a horizontal surface for the thin-walled bearing 18 to lay flat. The electromagnet 17, in the present embodiment even, two electromagnets 17 aligned with the horizontal plane are arranged on the horizontal plane of the workbench 14, and the two electromagnets 17 are arranged symmetrically about the axis of the thin-walled bearing 18. The two displacement sensors 11 are all located above the workbench 14 and the contacts of the displacement sensors 11 are arranged downwards. The two displacement senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com