Current collector and preparation method and application thereof

A technology of current collectors and functional membranes, applied in electrode current collector coating, electrode manufacturing, electrode carrier/current collector, etc., can solve the problem of low safety performance of lithium-ion batteries, reduce weight, improve energy density, improve The effect of safety features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

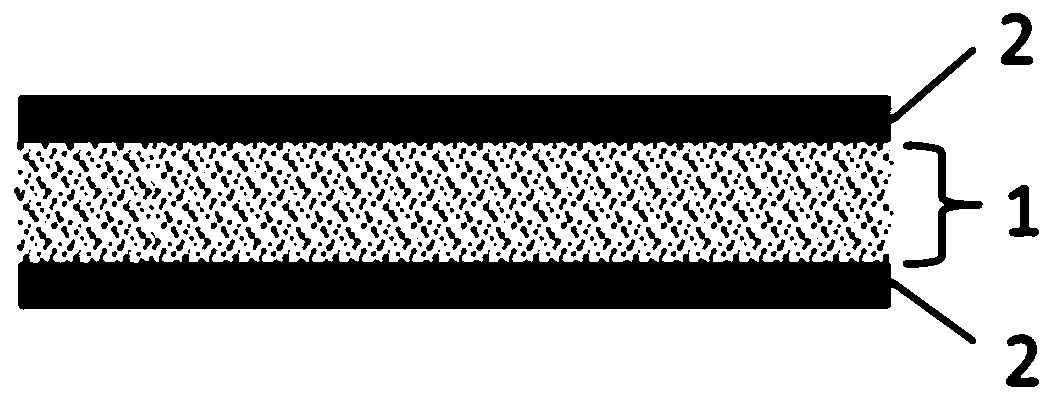

[0054] In the current collector provided in this embodiment, the functional film layer is obtained from 90 parts of polyethylene terephthalate PET and 10 parts of antimony trioxide, and a metal aluminum layer is provided on the upper surface and the lower surface of the functional film layer for use as The positive electrode current collector material is provided with a metal copper layer on the upper surface and the lower surface of the functional film layer to be used as the negative electrode current collector material.

[0055] The current collector can be prepared as follows:

[0056] 1) Melt and knead 90 parts of polyethylene terephthalate PET and 10 parts of antimony trioxide at 265°C for 20 minutes to obtain a mixed slurry, which is sequentially extruded, stretched, and cooled to obtain a thickness It is a functional film layer of 1 μm.

[0057] After testing, the flame retardant grade of the functional film layer is V1 grade, and the oxygen index is 28.

[0058] 2) ...

Embodiment 2-1

[0070] In the current collector provided in this embodiment, the functional film layer is obtained from 99 parts of polypropylene PP and 1 part of zinc phosphate, and a metal aluminum layer is set on the upper surface and the lower surface of the functional film layer as a positive electrode current collector material. A metal copper layer is arranged on the upper surface and the lower surface of the film layer to be used as a negative electrode current collector material.

[0071] The current collector can be prepared as follows:

[0072] 1) Melt and knead 99 parts of polypropylene PP and 1 part of zinc phosphate at 170°C for 30 minutes to obtain a mixed slurry, which is sequentially extruded, stretched, and cooled to obtain a functional film layer with a thickness of 5 μm.

[0073] The flame retardant grade of the tested functional film layer is V2, and the oxygen index is 26.

[0074] 2) A metal aluminum layer with a thickness of 2 μm was plated on both sides of the functi...

Embodiment 2-2

[0079] In the current collector provided in this embodiment, the functional film layer is obtained by 95 parts of polypropylene PP and 5 parts of zinc phosphate, and a metal aluminum layer is set on the upper surface and the lower surface of the functional film layer as the positive electrode current collector material. A metal copper layer is arranged on the upper surface and the lower surface of the film layer to be used as a negative electrode current collector material.

[0080] The current collector can be prepared as follows:

[0081] 1) Melt and knead 95 parts of polypropylene PP and 5 parts of zinc phosphate at 170°C for 30 minutes to obtain a mixed slurry, which is sequentially extruded, stretched, and cooled to obtain a functional film layer with a thickness of 5 μm.

[0082] The flame retardant grade of the tested functional film layer is V1, and the oxygen index is 28.

[0083] 2) The upper surface and the lower surface of the functional film layer are respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com