Flexible heating sheet and manufacturing method thereof

A heating sheet, flexible technology, applied in the field of flexible heating sheet and its preparation, can solve the problems of poor mechanical properties, low electrothermal conversion efficiency, poor flexibility and plasticity of the heating sheet, and achieve uniform heating, light weight, and excellent electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention provides a method for preparing a flexible heating sheet, comprising the following steps:

[0038] S10. Obtain a carbon nanotube fiber bundle and a substrate, and arrange the carbon nanotube fiber bundle on the substrate according to a preset circuit diagram to obtain a substrate with a fiber circuit diagram;

[0039] S20. Depositing a rubber mixed material on the surface of the side of the substrate where the fiber circuit pattern is arranged, so that the area of the fiber circuit pattern arranged on the substrate except the end of the carbon nanotube fiber bundle is solid-sealed on the surface In the above rubber compound material, a heating sheet is formed on the substrate;

[0040] Wherein, the rubber compound material includes rubber and curing agent.

[0041]The preparation method of the flexible heating sheet provided by the embodiment of the present invention, first, arrange the carbon nanotube fiber bundles on the subs...

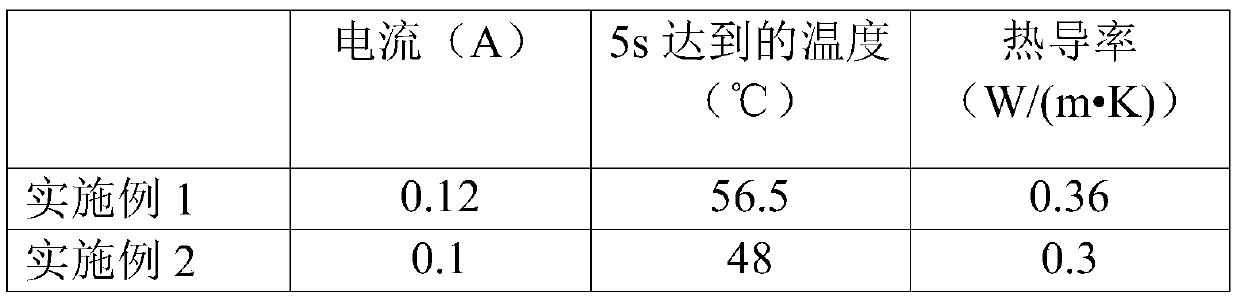

Embodiment 1

[0068] A flexible heating sheet, comprising the steps of:

[0069] ① Deposit a catalyst layer on the substrate, place it in a chemical vapor deposition reactor and pass in a protective gas, heat up to 700°C, then pass in a carbon source gas, and react for about 5 minutes to generate uniformly grown carbon nanotube arrays on the substrate Pull out a carbon nanotube film with a width of 7.5cm from the carbon nanotube array, use a twist meter to twist the above film, and the twist is 1300tpm to obtain a carbon nanotube fiber filament; 10 carbon nanotube fiber filaments are merged forming a bundle of carbon nanotube fiber bundles to obtain carbon nanotube fiber bundles.

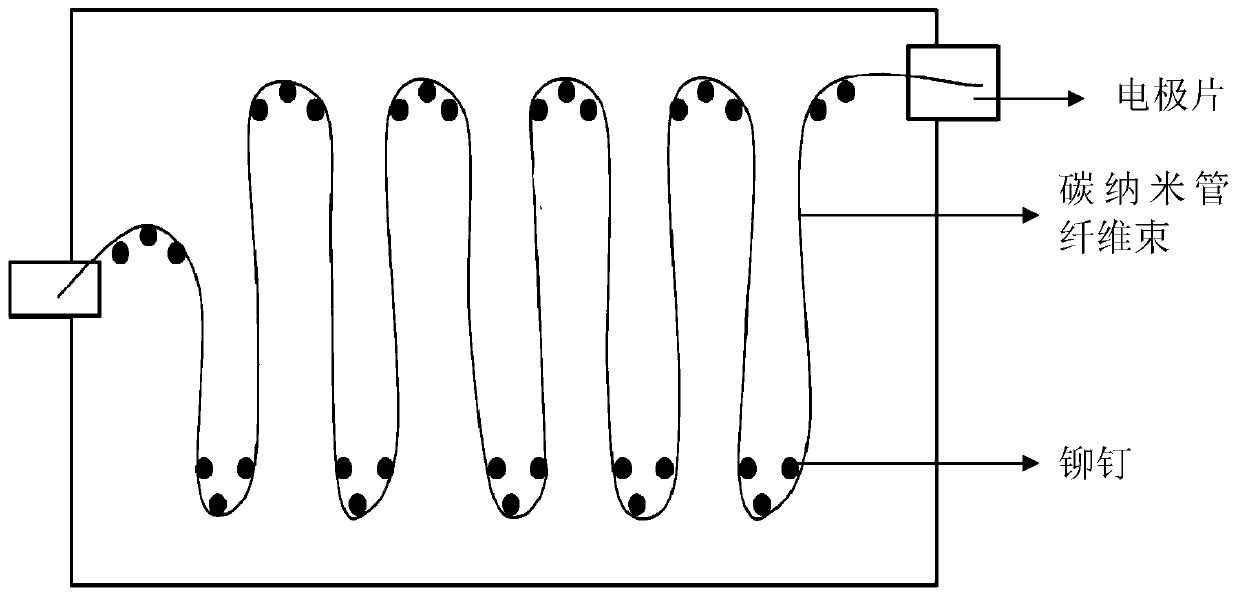

[0070] ② Obtain a template, the holes on the template are equipped with rivets, the electrode pads are located on the gasket, and the single carbon nanotube fiber bundle is wound according to the circuit diagram, as shown in the attached figure 1 shown, and bond the end to the electrode sheet.

[0071] ③ Place...

Embodiment 2

[0074] A flexible heating sheet, comprising the steps of:

[0075] ① Deposit a catalyst layer on the substrate, place it in a chemical vapor deposition reactor and pass in a protective gas, heat up to 700°C, then pass in a carbon source gas, and react for about 5 minutes to generate uniformly grown carbon nanotube arrays on the substrate Pull out a carbon nanotube film with a width of 7.5cm from the carbon nanotube array, use a twist meter to twist the above film, and the twist is 1300tpm to obtain a carbon nanotube fiber filament; 5 carbon nanotube fiber filaments are merged forming a bundle of carbon nanotube fiber bundles to obtain carbon nanotube fiber bundles.

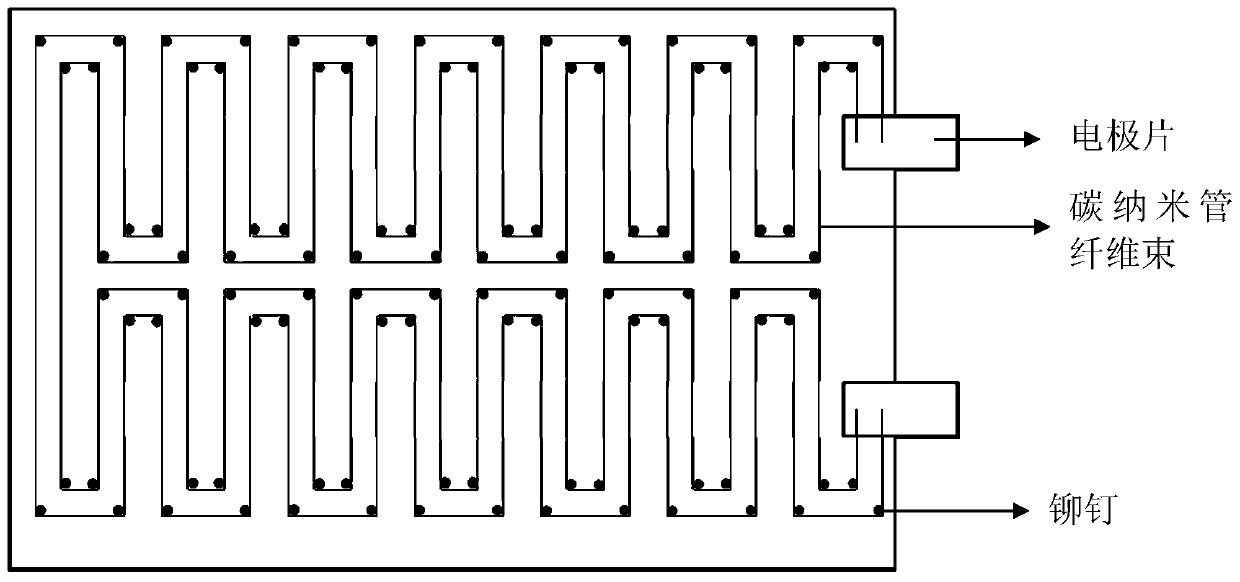

[0076] ② Obtain a template, the holes on the template are equipped with rivets, the electrodes are located on the spacers, and the two carbon nanotube fiber bundles are wound according to the circuit diagram, as shown in the attached figure 2 shown, and bond the end to the electrode sheet.

[0077] ③ Place the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com