Method for preparing cigarette filter capsule from lignin-carbohydrate coated essence

A carbohydrate and lignin technology, applied in the fields of tobacco, application, and tobacco treatment, can solve the problems of unreported natural rigid wrapping materials, insufficient brittleness, and weak popping feeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

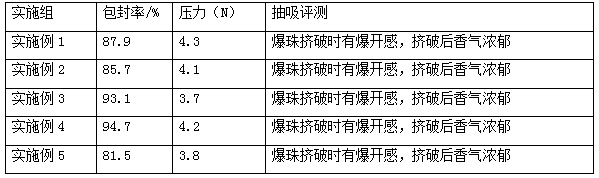

Examples

Embodiment 1

[0027] A kind of lignin-carbohydrate-coated essence prepares the method for cracking pearls for cigarettes, comprising the following steps:

[0028] (1) Prepare castor oil as the oil phase, menthol as the essence, and choose spruce LCC.

[0029] The extraction method of spruce LCC is as follows: weigh a certain amount of dry spruce wood powder, wrap it in quantitative filter paper with a thin thread, put it in a Soxhlet extractor, add toluene / ethanol (2 / 1, v / v) , extracted in a water bath for 6h. The extracted spruce wood powder was placed in a ball mill for vibration milling for 64 hours. Put the ball-milled spruce wood powder in quantitative filter paper and wrap it with a thin thread, put it in a Soxhlet extractor, add dioxane / water (96 / 4, v / v), and extract it in an oil bath. Extracted for 72h to obtain solution and insoluble matter. After the insoluble matter is fully dried, add acetic acid / water (1 / 1, v / v) and extract for 24 hours to obtain the insoluble matter and sol...

Embodiment 2

[0036] A kind of lignin-carbohydrate-coated essence prepares the method for cracking pearls for cigarettes, comprising the following steps:

[0037] (1) Prepare peanut oil as the oil phase, menthol as the essence, and poplar LCC. The extraction method of Poplar LCC is as in Example 1.

[0038] (2) According to parts by mass, 0.6 part of oil-soluble essence solution was dissolved in 100 parts of oil phase to obtain oil phase solution; 1 part of lignin-carbohydrate complex was dissolved in 100 parts of water to obtain water phase solution.

[0039] (3) Mix the oil phase solution and the water phase solution at a volume ratio of 15:100; send them to a high-speed shearing machine after mixing, and shear at a high speed of 5000rpm for 2min; Quality, cycle 2 times to obtain emulsion system.

[0040] (4) Add 10 times the volume of anhydrous methanol drop by drop to the emulsion system, let it stand until the precipitation no longer increases, and then let it stand for 30 minutes to...

Embodiment 3

[0044] A kind of lignin-carbohydrate-coated essence prepares the method for cracking pearls for cigarettes, comprising the following steps:

[0045] (1) Prepare peanut oil as the oil phase, vanillin as the essence, and use wheat straw LCC. The extraction method of wheat straw LCC is as in Example 1.

[0046] (2) Dissolving 8 parts of oil-soluble essence solution in 100 parts of oil phase in parts by mass to obtain an oil phase solution; dissolving 8 parts of lignin-carbohydrate complex in 100 parts of water to obtain a water phase solution.

[0047](3) Mix the oil phase solution and the water phase solution at a volume ratio of 30:100; send them to a high-speed shearing machine after mixing, and shear at a high speed of 15,000 rpm for 8 minutes; Quality, cycled 3 times to obtain emulsion system.

[0048] (4) Add 100 times the volume of glycerol drop by drop to the emulsion system, let it stand until the precipitation no longer increases, and then let it stand for 60 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com