Copper-based catalyst as well as preparation method and application thereof

A copper-based catalyst and solvent technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of cost reduction, low mass production cost, and high hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

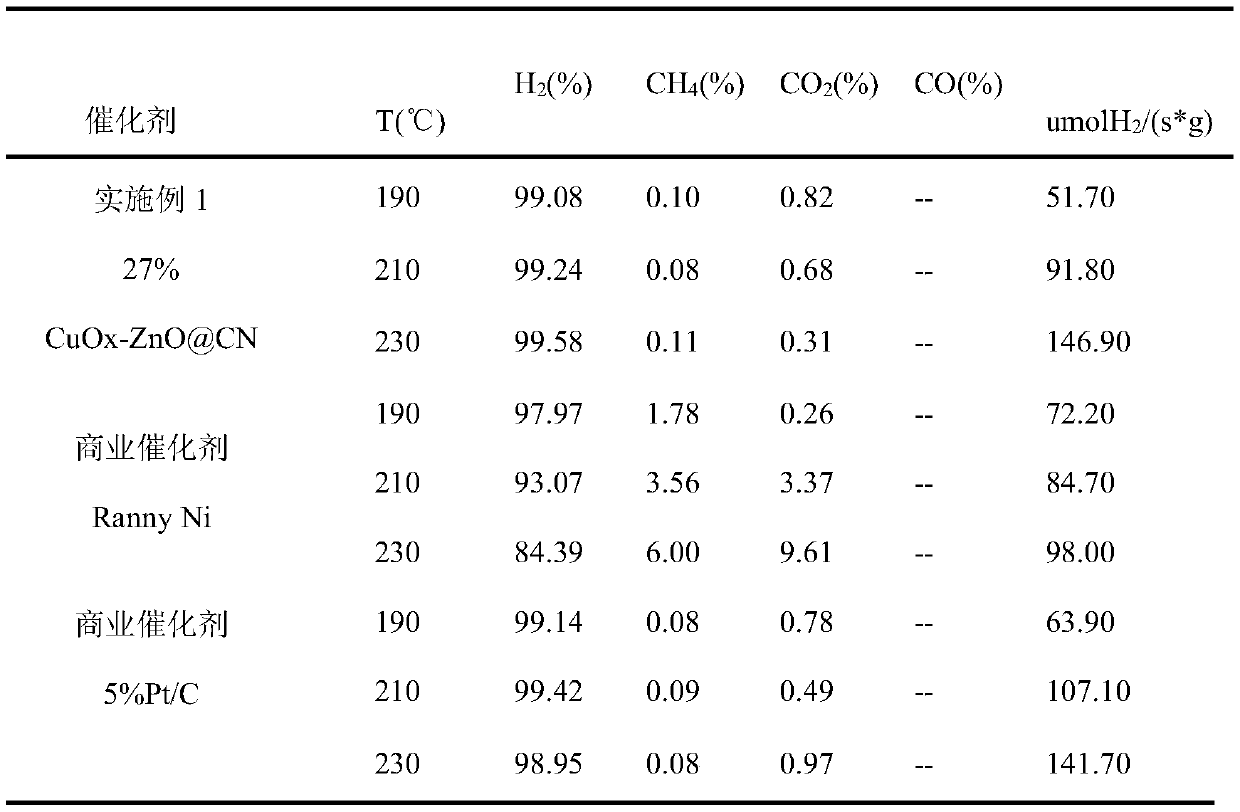

Examples

Embodiment 1

[0032] 1. Dissolve 18mmol zinc nitrate hexahydrate in 50ml methanol, sonicate for 5min, and mark it as solution A;

[0033] 2. Dissolve 72mmol 2-methylimidazole in 50ml methanol, sonicate for 5min, and mark it as solution B;

[0034] 3. Pour liquid B into liquid A, put it in an oil bath at 60°C for 24 hours to obtain a white precipitate, dry the precipitate at 60°C to obtain a ZIF-8 carrier, and dry it at 200°C for 2 hours in air to remove the adsorbed The small molecule organic matter in the zif-8 channel is used to prepare the activated ZIF-8 carrier.

[0035] 4. Take 400mg of the activated ZIF-8 carrier in 12ml of 0.024mmol / ml copper nitrate aqueous solution and stir at room temperature for 24h, centrifuge the obtained precipitate and dry it at 60°C, and reduce it under hydrogen at 200°C for 2h to obtain a copper-based catalyst. Among them, the loading amount of CuOx is 27wt% (27%CuOx / ZnO@CN) (x=0, 0.5 and 1).

Embodiment 2

[0037] The difference from Example 1 is that in step 4, 400 mg of the activated ZIF-8 carrier is stirred in 12 ml of 0.008 mmol / ml copper nitrate aqueous solution for 24 hours at room temperature to obtain 14% CuOx-ZnO@CN (x=0, 0.5 and 1).

Embodiment 3

[0039] The difference from Example 1 is that in step 4, 400 mg of the activated ZIF-8 carrier was stirred in 12 ml of 0.16 mmol / ml copper nitrate aqueous solution for 24 hours at room temperature to prepare 21% CuOx-ZnO@CN (x=0, 0.5 and 1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com