Preparation method of foldable fiber reinforced resin based composite truss, and truss

A fiber-reinforced resin and composite material technology, applied in the field of trusses, can solve the problems of large space occupation and heavy truss quality, and achieve the effects of saving space, compact structure and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

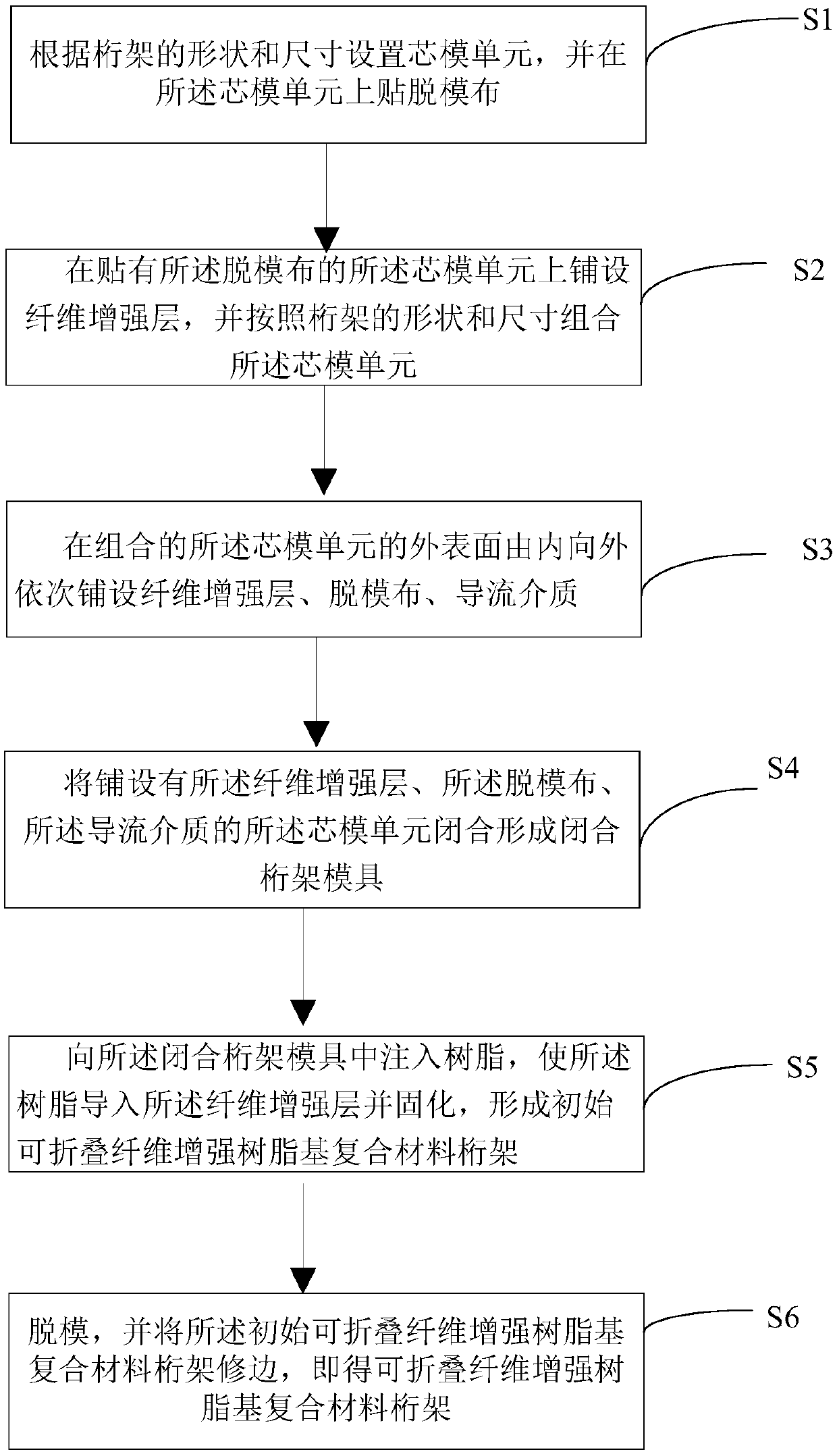

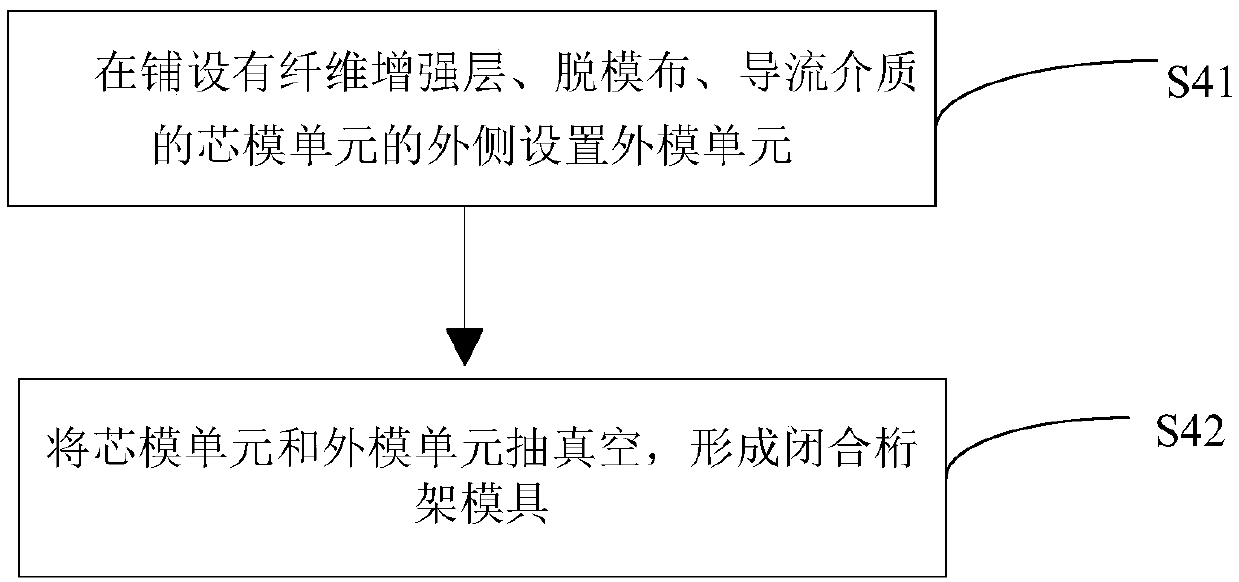

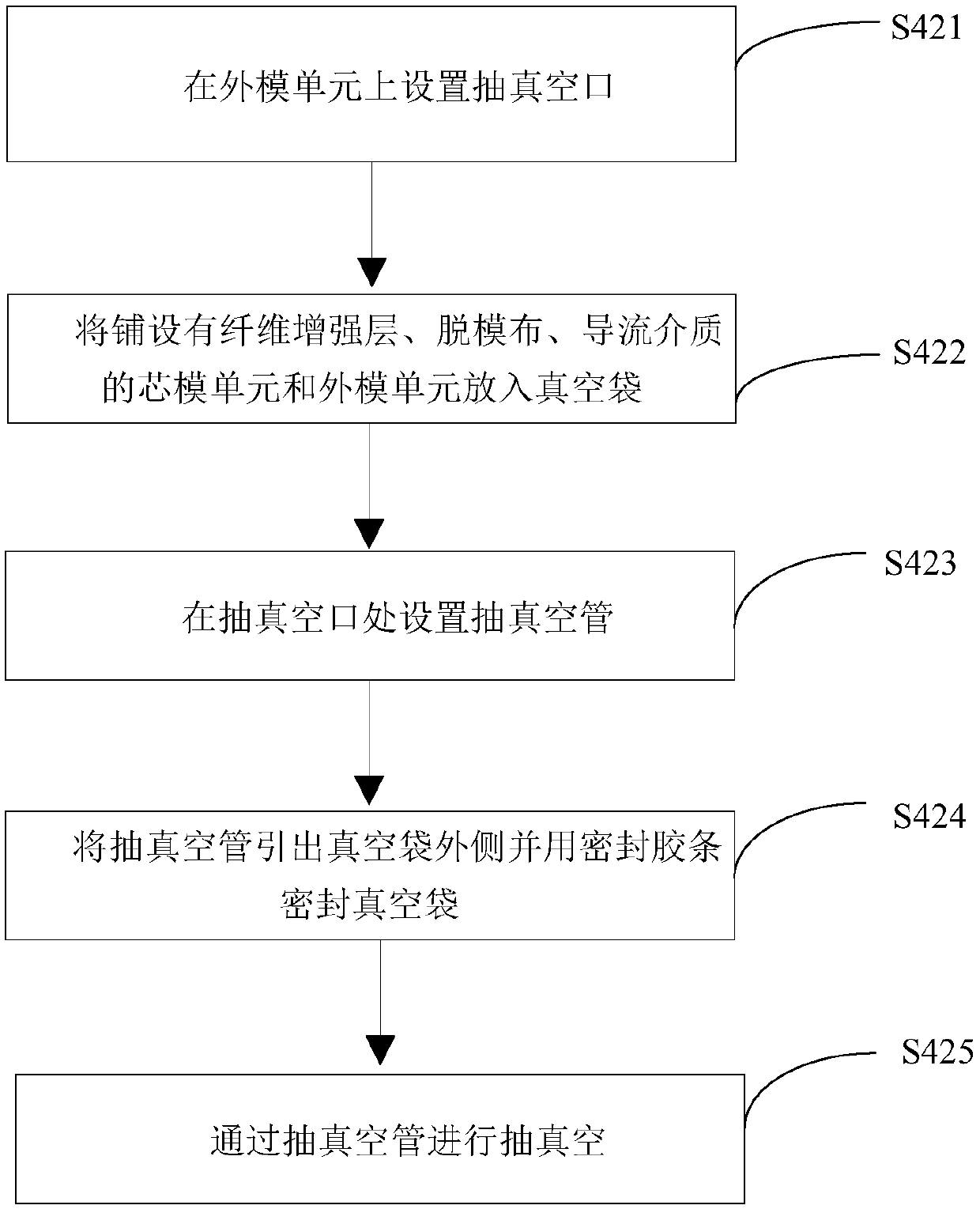

[0059] combine Figure 1-6 Shown, a kind of preparation method of foldable fiber-reinforced resin matrix composite truss comprises:

[0060]S1. According to the shape and size of the truss, the mandrel unit 1 for preparing the structural unit of the truss is set, and the release cloth is pasted on the mandrel unit 1, wherein the mandrel unit 1 includes an end mandrel 11 and a reinforcing mandrel 12 , support mandrel 13, and end mandrel 11, reinforcement mandrel 12, support mandrel 13 from the direction shown in the figure, from left to right, according to end mandrel 11, reinforcement mandrel 12, support mandrel 13, reinforcement core The order of the mold 12 and the end mandrel 11 is arranged to form a mandrel unit 1, that is, the end mandrel 11 and the reinforcing mandrel 12 are located at both ends of the supporting mandrel 13, and the reinforcing mandrel 12 is located at the end mandrel 11 and the adjacent end Between the supporting mandrels 13 of the mandrel 11; the supp...

Embodiment 2

[0083] combine Figure 7-10 As shown, a foldable fiber-reinforced resin-based composite truss includes an upper run 3 and a lower run 4; a plurality of supporting webs 5 are arranged between the upper run 3 and the lower run 4; the upper run 3 and the lower run 4 The ends are connected by the end web 6; a reinforcing web 7 is arranged between the end web 6 and the supporting web 5 adjacent to the end web 6; one end of the reinforcing web 7 is connected with the upper chord beam 3, and the The other end is connected with the lower string 5; the upper string 3, the lower string 4, the support web 5, the end web 6, and the reinforcement web 7 are made of fiber-reinforced resin-based composite materials.

[0084] In this embodiment, the upper chord 3, the lower chord 4, the support web 5, the end web 6 and the reinforcement web 7 constituting the foldable fiber-reinforced resin-based composite truss are all made of fiber-reinforced resin-based composite materials, so that this imp...

Embodiment 3

[0095] combine figure 1 , figure 2 and Figure 7 As shown, a truss-type retractable space capsule includes a plurality of cabin support beams 8 and a plurality of head support beams 9; the cabin support beams 8 and head support beams 9 are reinforced by a plurality of the above-mentioned foldable fibers Resin-based composite material truss connection structure; the two ends of multiple cabin support beams 8 are supported by hoop support beams 81 to form a cylindrical frame structure 82; the two ends of multiple head support beams 9 are supported by hoop support beams 81 and ring Support to the butt joint 83 to form a circular platform frame structure 84; the circular platform frame structure 84 extends to the outside of the cylindrical frame structure 82 along the axial direction of the cylindrical frame structure 82; the hoop supporting beam 81 and the hoop butt joint 83 are all made of fiber reinforced resin Made of base composite material. Among them, in order to enhanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com