Automatic electric energy storage pipe column conveying device for well servicing

An automatic conveying device, electric technology for wells, applied in the transmission device, drill pipe, casing and other directions, can solve the problems of leakage loss, low transmission efficiency, loss along the way, etc., to solve oil leakage, improve transmission efficiency, The effect of simplifying the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

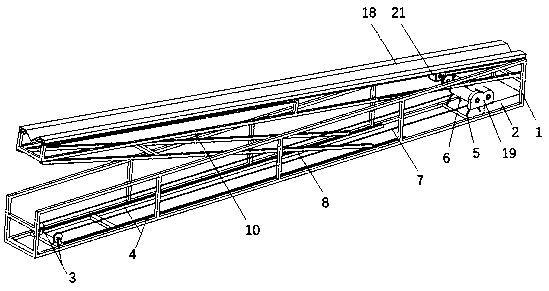

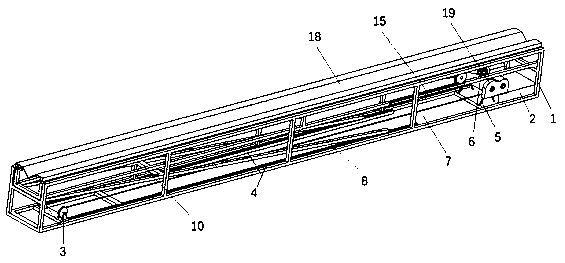

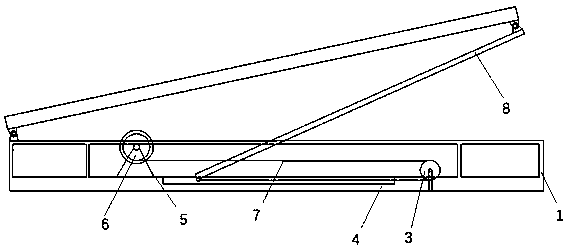

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] see figure 1 , an electric energy storage string automatic delivery device for well workover, comprising a base body; the base body is hinged with a lifting mechanism; the lifting mechanism is connected with a propulsion mechanism; the transfer mechanism is fixed on the base body, The output shaft is respectively connected with the propulsion mechanism and the lifting mechanism.

[0023] see figure 1 , 3 , The base body includes a base steel frame 1, a support vertical plate 2, a fixed pulley block 3, and a limit steel channel set 4. One end of the base steel frame 1 is fixed with a supporting vertical plate 2; the fixed pulley block 3 is fixed on the other end of the base steel frame 1; The lifting mechanism includes a reel frame 5, a reel 6, a flexible rope 7, a lifting arm 8, and a limit roller group 9; the reel frame 5 is fixed on the base steel frame 1; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com