High-temperature tunnel type electrothermal dynamic sintering furnace

A tunnel type, sintering furnace technology, applied in the direction of furnace, furnace material, furnace type, etc., can solve the problems of product scrapping, affecting sintering quality, high power of resistance wire, etc., and achieve the effect of maintaining sintering quality, simple structure and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

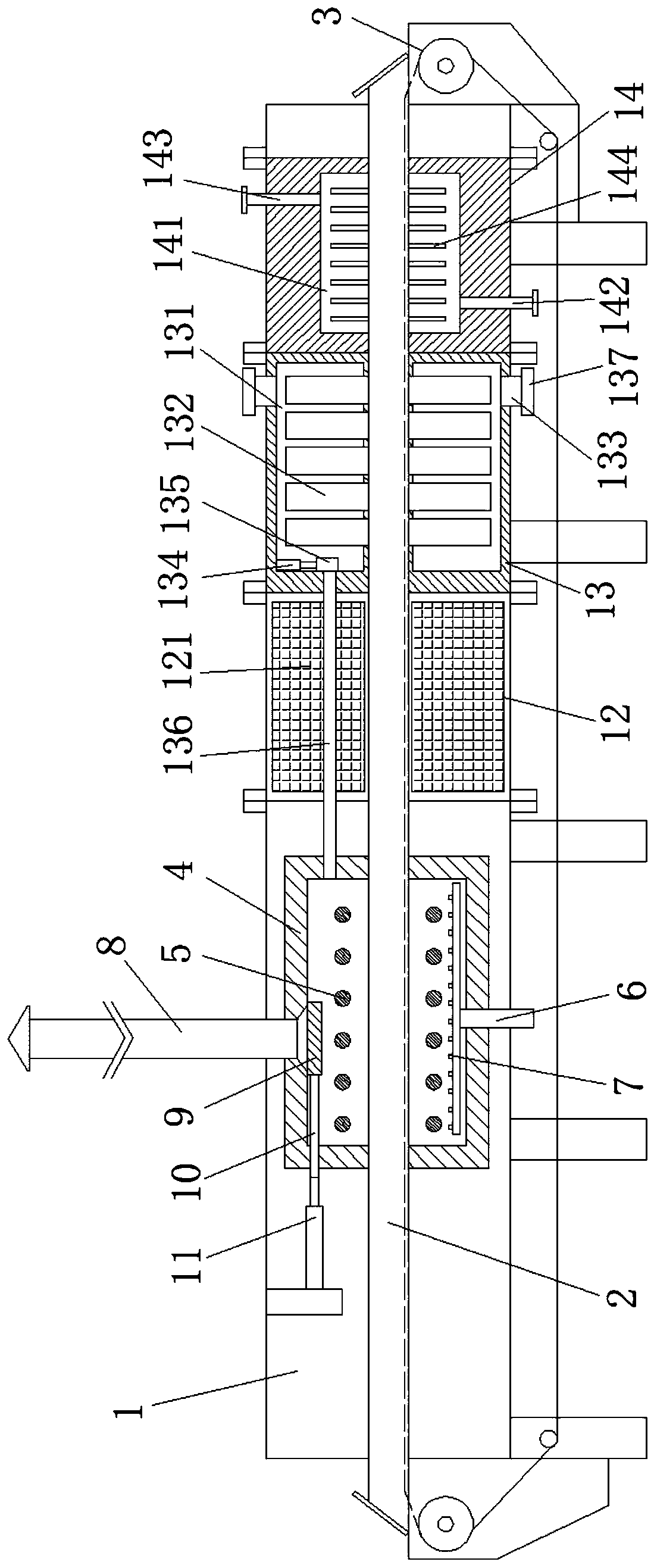

[0022] As an embodiment of the present invention, a heating furnace 4, a heat preservation section 12, a passive heat dissipation section 13 and an active heat dissipation section 14 are sequentially arranged inside the heat insulation wall 1 from left to right; There is an annular thermal insulation material 121, the thermal insulation material 121 wraps the tunnel muffle tank 2, uses the thermal insulation section 12 for continuous sintering, the passive cooling section 13 for preliminary heat dissipation, and the active cooling section 14 for rapid cooling, To meet the production process requirements of electronic components.

[0023] As an embodiment of the present invention, an annular cavity 131 is opened in the passive cooling section 13, and the cavity 131 wraps a section of the tunnel-type muffle tank 2, and the tunnel-type muffle tank 2 is provided with a No. 1 heat sink 132, the No. 1 heat sink 132 is located inside the cavity 131, and a plurality of air inlets 133 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com