Magnetic gear speed-regulating permanent-magnet synchronous traction machine

A technology of synchronous traction machines and magnetic gears, applied in the field of traction machines, can solve the problems of large overall weight, large stator size, and large number of windings, etc., to reduce volume and weight, reduce longitudinal length, and directly transmit torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

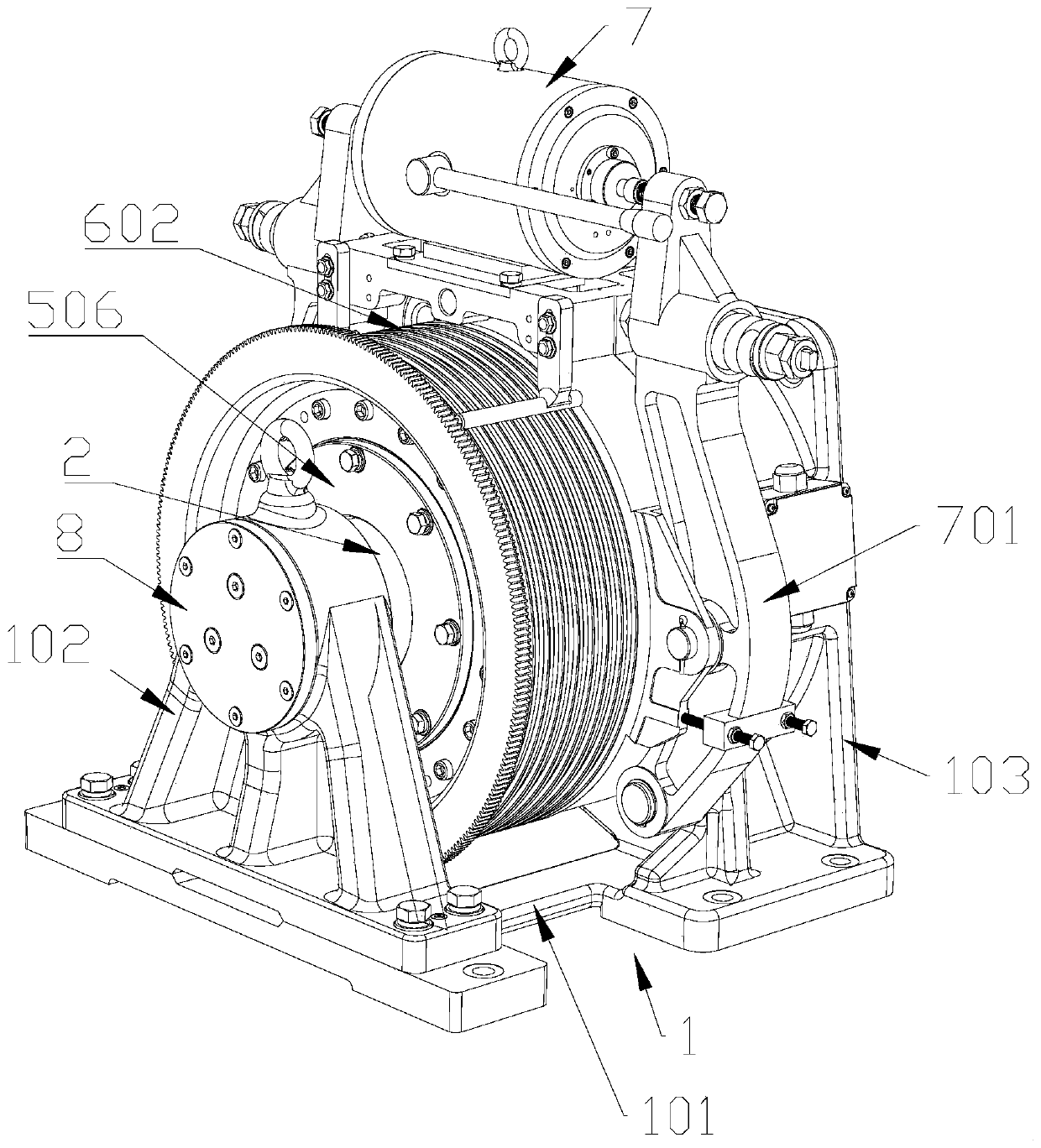

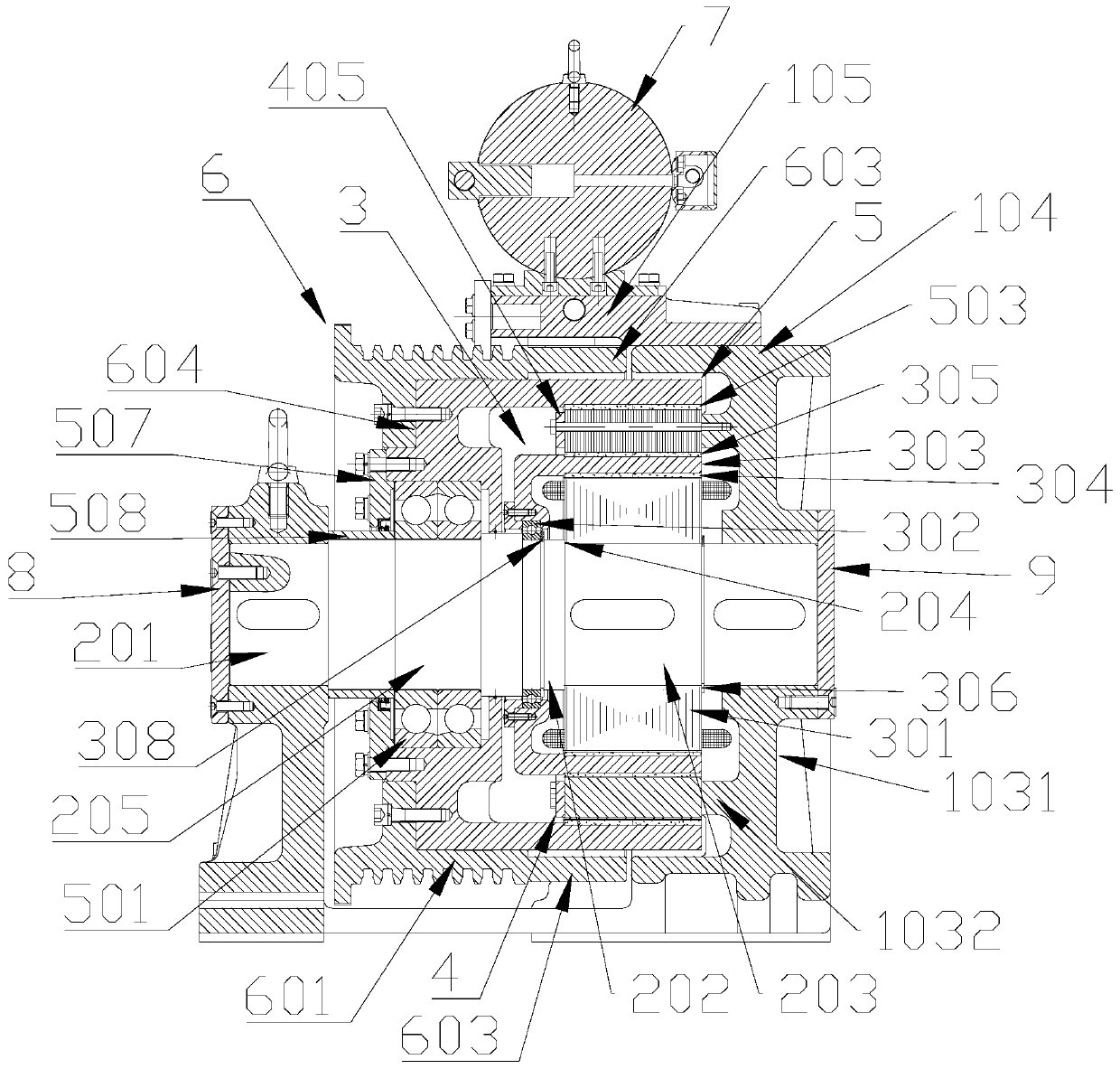

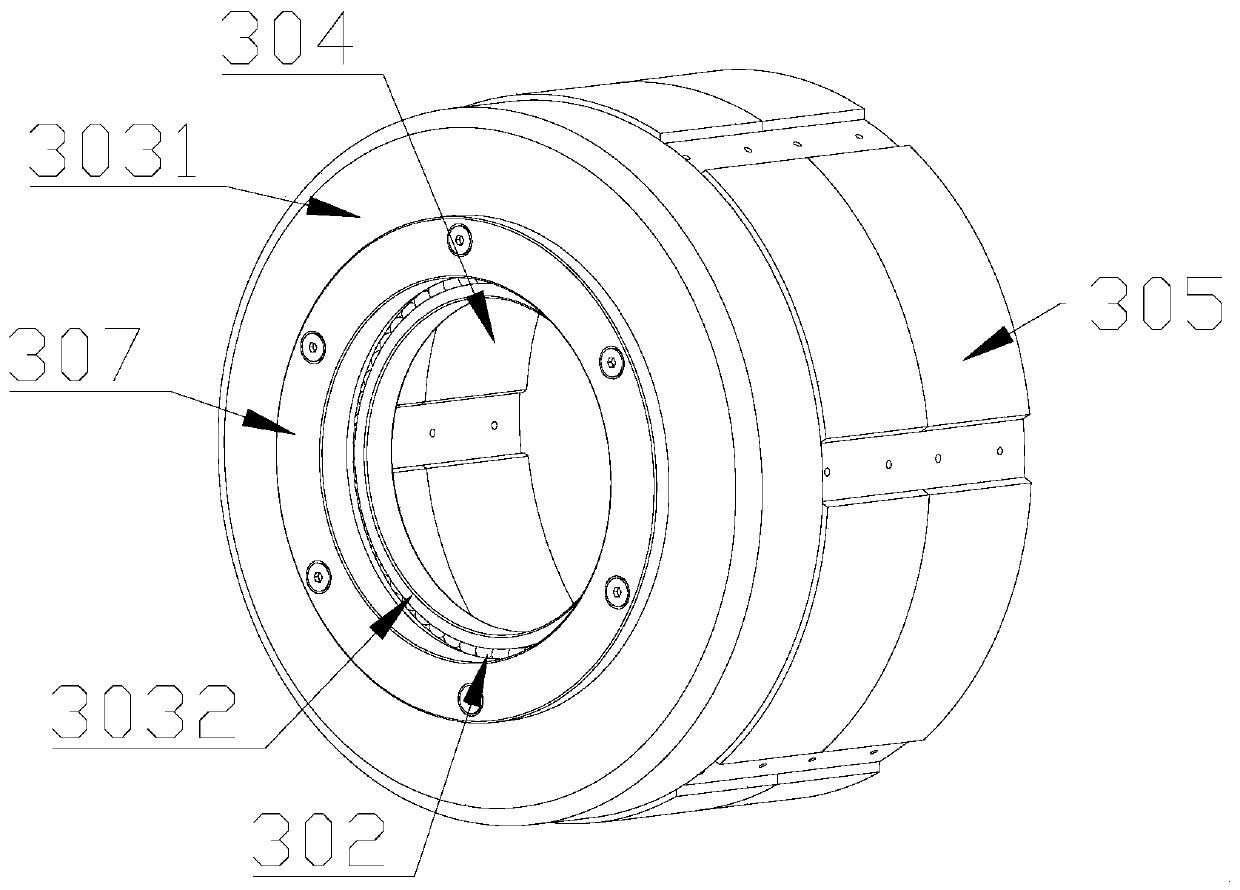

[0026] Such as Figure 1 - Figure 1 As shown, the magnetic gear speed-regulating permanent magnet synchronous traction machine of this embodiment includes:

[0027] The base 1 has a bottom support 101 and a front support 102 and a rear support 103 on the bottom support 101; the base is the same as the existing base, there are several main combinations, one is the bottom support , the front bracket and the rear bracket are independent parts, which are fixed together by fasteners. The other structure is integral casting, and the bottom support body, front bracket and rear main frame are integrated structures; there is also a front bracket. Or one of the parts of the rear bracket is cast together with the bottom support body to form an integrated structure, and then the other part is a separate part, which is fixed with the other two components by fasteners to form an integrated structure for carrying the drag The basis of each functional component of the engine.

[0028] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com