A kind of bicycle cushion and its molding process

A molding process, bicycle technology, applied in bicycle accessories, bicycle saddles, transportation and packaging, etc., can solve the problems of insufficient rider comfort, uneven force on the seat cushion, and reduced elasticity of the seat cushion, etc. Good durability, increased softness, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

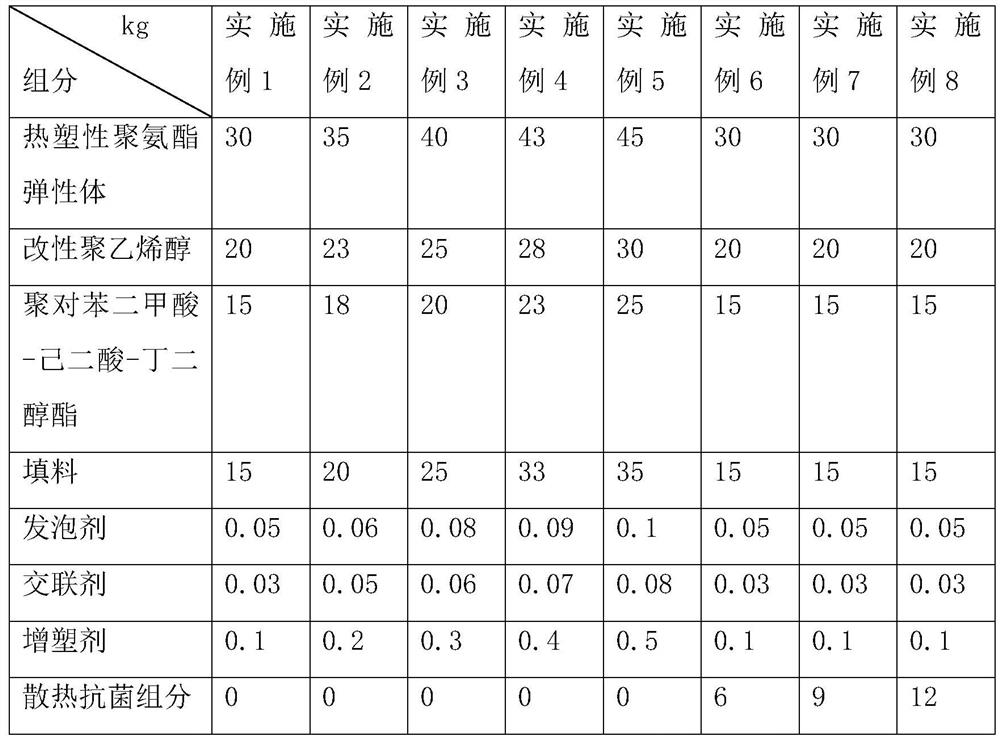

Method used

Image

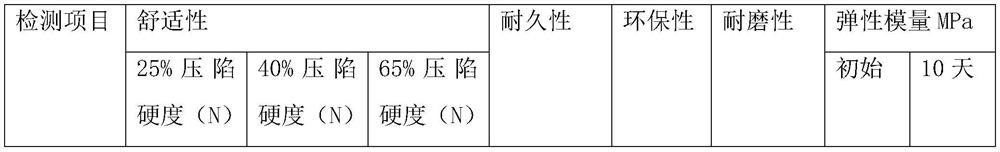

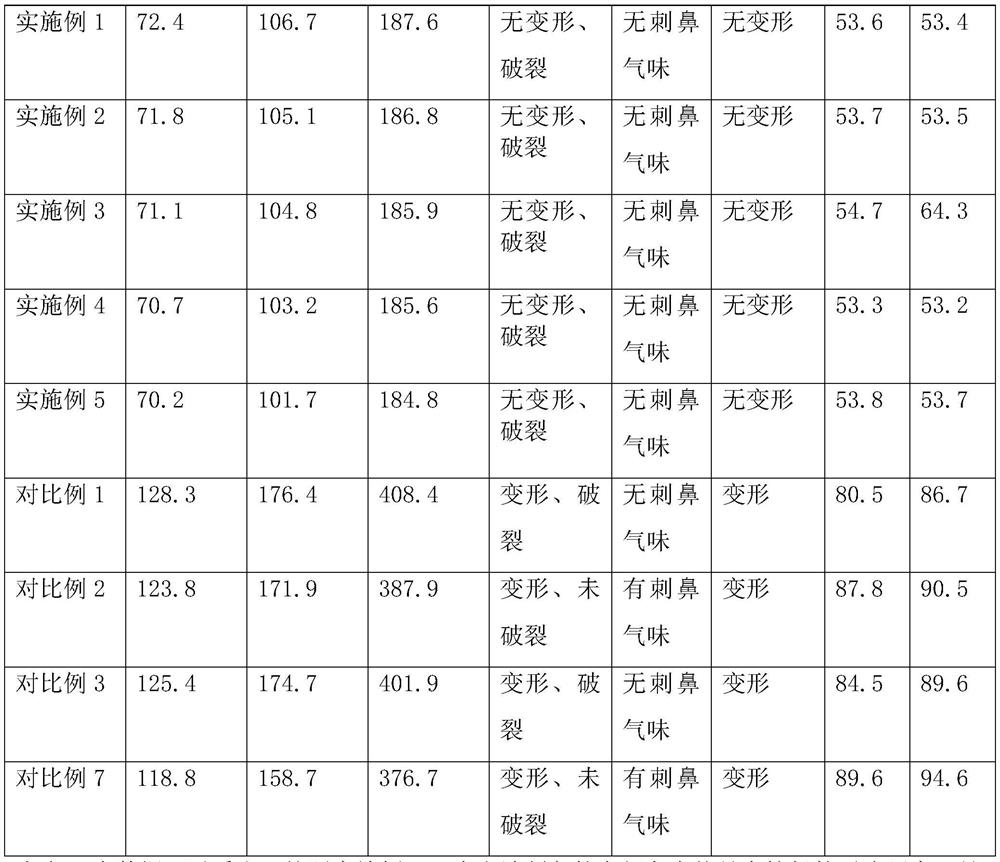

Examples

preparation example 1-3

[0043] In the preparation example 1-3, the starch of canna taro was selected from the product number of 2019 sold by Guangxi Tianlin Rongan Agricultural Development Co., Ltd., and the gelatin was selected from the gelatin and polyvinyl alcohol of the product number of T6325 sold by Henan Guanqi Biotechnology Co., Ltd. The polyvinyl alcohol with the brand name PVA2699 sold by Shanghai Yingjia Industrial Development Co., Ltd. and the silicon dioxide are selected from the silicon dioxide and diatom mud with the product number T-1 sold by Tongqi Chemical (Shanghai) Co., Ltd., and the diatom mud is selected from Dongguan Diatom mud sold by Jinpai Industry and Trade Co., Ltd. is JP0010.

preparation example 1

[0044] Preparation example 1: Mix 0.8kg canna starch, 0.8kg gelatin and 0.3kg boric acid, add 1.2kg polyvinyl alcohol, and continuously feed formaldehyde gas, seal and stir for 2 hours, take it out, add 0.6kg silicon dioxide and 0.3kg Diatom mud is mixed and stirred evenly to prepare modified polyvinyl alcohol, the degree of polymerization of polyvinyl alcohol is 2550, and the degree of alcoholysis is 99%.

preparation example 2

[0045] Preparation example 2: Mix 1.3kg canna starch, 1.2kg gelatin and 0.5kg boric acid, add 2.3kg polyvinyl alcohol, and continuously feed formaldehyde gas, seal and stir for 3 hours, take it out, add 0.9kg silicon dioxide and 0.4kg silicon dioxide The algae mud is mixed evenly to prepare modified polyvinyl alcohol, the degree of polymerization of the polyvinyl alcohol is 2600, and the degree of alcoholysis is 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com