Near-infrared fluorescent powder, preparation and application method thereof, near-infrared light source and preparation method of near-infrared white light source

A fluorescent powder and near-infrared technology, which is applied to optical elements, light sources, chemical instruments and methods for changing the spectral characteristics of emitted light, and can solve the problems of narrow bandwidth, small volume, and large volume of near-infrared light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] According to the general chemical formula Ca of the near-infrared fluorescent powder 1.06 Lu 1.94 Cr 0.06 Mg 1.94 Si 3 o 12 The stoichiometric ratio of each element in CaCO is weighed 3 、Lu 2 o 3 , MgO, SiO 2 and Cr 2 o 3 , after fully grinding and mixing, put it into a high-purity corundum crucible, wrap it in carbon powder, keep it warm at 1320°C for 8 hours, cool and discharge the material, grind it a little, wash, filter, and dry, and then it has broadband emission characteristics. near-infrared phosphors.

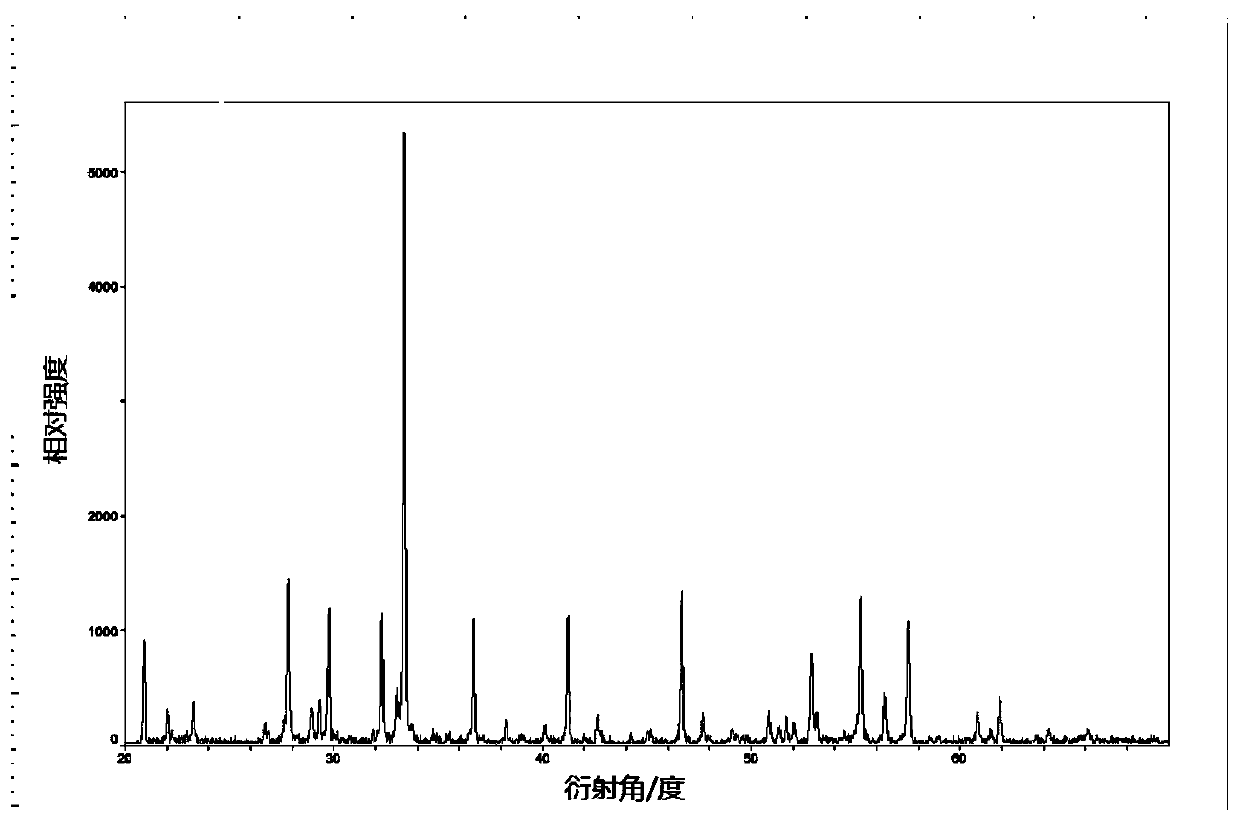

[0069] Carry out XRD analysis to the near-infrared fluorescent powder that embodiment 1 obtains, and XRD diffraction pattern is as follows figure 1 shown; from figure 1 It can be seen from the curve in that the phosphor has a garnet structure.

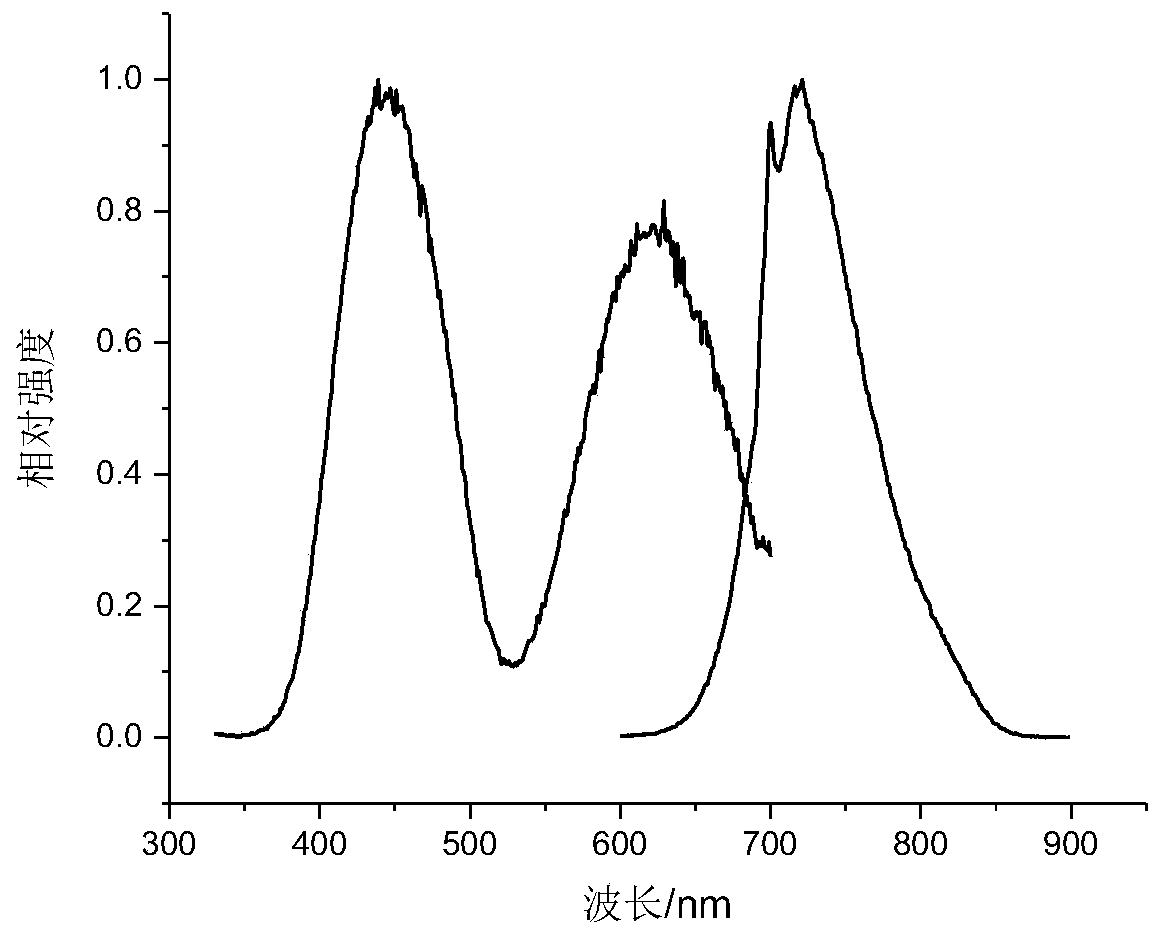

[0070] The emission spectrum and the excitation spectrum of the near-infrared fluorescent powder that embodiment 1 obtains are analyzed, and the results are as follows: figure 2 shown, from figure 2 It c...

Embodiment 2

[0073] According to the general chemical formula Ca of the near-infrared fluorescent powder 1.05 Lu 1.95 Cr 0.05 Mg 1.95 Si 3 o 12 The stoichiometric ratio of each element in CaCO is weighed 3 、Lu 2 o 3 , MgO, SiO 2 and Cr 2 o 3 , after fully grinding and mixing, put it into a high-purity corundum crucible, and keep it warm at 1320°C for 8 hours in an air atmosphere. near-infrared phosphors.

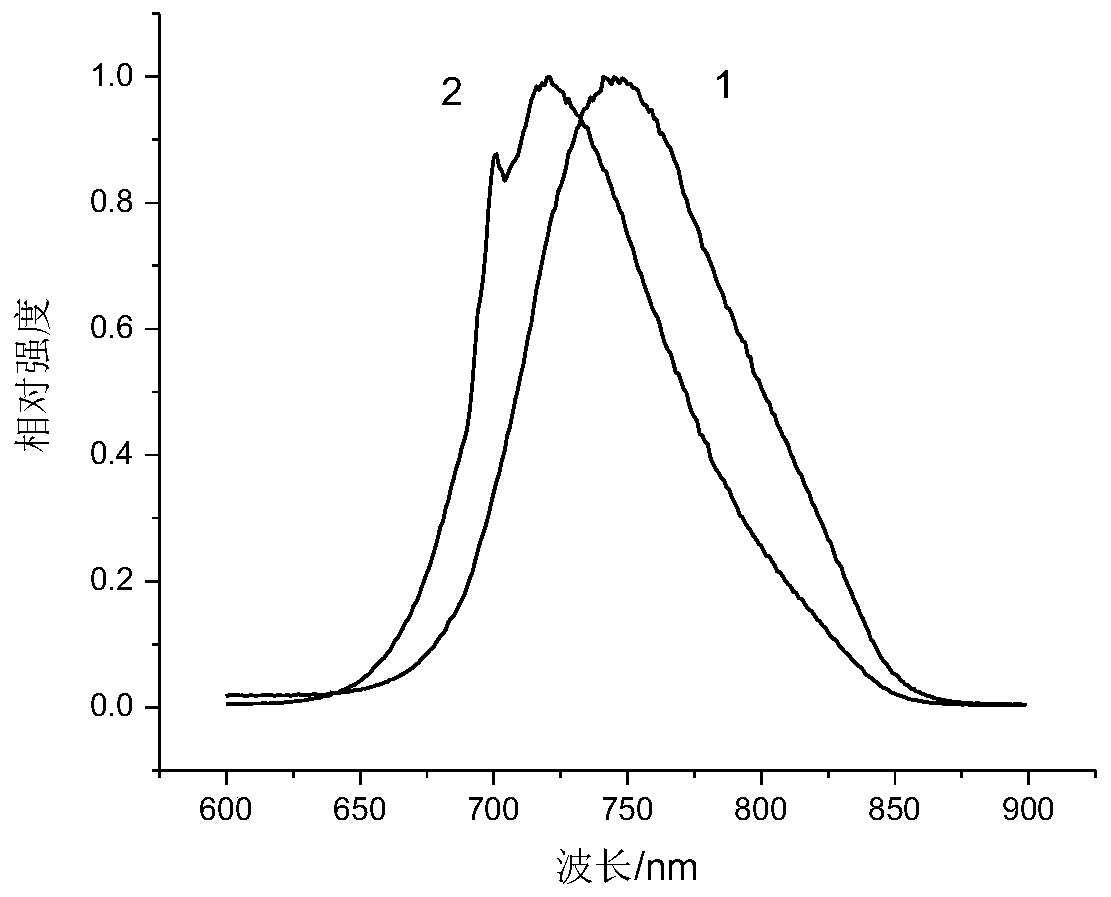

[0074]Comparing the emission spectra of Example 1 and Example 2, it can be seen that the luminescence peak position can be effectively adjusted by adjusting the components, which helps to realize the adjustable emission of the light source.

[0075] Mix the near-infrared fluorescent powder of Example 2 with 490nm blue-green fluorescent powder, 535nm green fluorescent powder and 660nm red fluorescent powder in a mass ratio of 20:1:10:1, and mix with epoxy resin to obtain fluorescent powder-containing glue (phosphor powder mass fraction 40%), first bond and fix the 460nm blue L...

Embodiment 3

[0077] According to the general chemical formula Ca of the near-infrared fluorescent powder 2.8 Lu 0.2 Cr 0.05 sc 1.75 Mg 0.2 Si 3 o 12 The stoichiometric ratio of each element in CaCO is weighed 3 、Lu 2 o 3 , MgO, SiO 2 and Cr 2 o 3 , after fully grinding and mixing, put it into a high-purity corundum crucible, and keep it warm at 1320°C for 8 hours in a vacuum atmosphere. near-infrared phosphors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com