Method for removing isobutene from C4 hydrocarbon, and method for producing 1-butene and 2-butene

A technology for isobutene and carbon tetrahydrocarbons, applied in the field of isobutene removal, can solve the problems of large loss of 1-butene, loss of economic feasibility, unsuitability for 1-butene, etc., and achieve the effect of flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] In a sleeve reactor with a specification of φ32mm×1000mm, 200mL of KC110 macroporous strong-acid cation exchange resin (produced by Hebei Kairui Environmental Protection Technology Co., Ltd., the same below) is loaded. The reaction tube has a hot water jacket and can be passed into Hot water at a specified temperature removes the heat of reaction to keep the temperature inside the reaction tube constant. At a pressure of 1.60MPa and a temperature of 50°C, the mixed C4 containing 0.8% (wt) tert-butanol (composed of propylene 0.0595wt%; propane 0.04666wt%; isobutane 26.3208wt%; n-butane 13.75944wt%; Anti-butene 13.18326wt%; 1-butene 13.74807wt%; Isobutene 24.55937wt%; Butene 8.10257wt%; . The outlet of the tubular reactor was analyzed on-line through the high-pressure sampling valve for product composition. According to the reaction results, it is calculated that the conversion rate of isobutene is 85.0%, the conversion rate of 1-butene is 10.5%, and the conversion rate...

Embodiment 2

[0104] Put 200mL SiO in the casing reaction with a specification of φ32mm×1000mm 2 -Al 2 o 3 Catalyst (Al content is about 15wt%), the reaction tube is equipped with a hot water jacket, and hot water of a specified temperature can be introduced to keep the temperature inside the reaction tube constant. Under the conditions of pressure 1.60MPa and temperature 65°C, carbon-mixed C4 (composed of 0.0595wt% propylene; 0.04666wt% propane; 26.3208wt% isobutane; 13.75944wt% n-butane; 13.18326wt% trans-butene; 1-Butene 13.74807wt%; Isobutene 24.55937wt%; Butene 8.10257wt%; C5 0.22033wt%), at 240g / h (volume space velocity 1h -1 ) rate into the tubular reactor for superposition reaction. The outlet of the tubular reactor was analyzed on-line through the high-pressure sampling valve for product composition. According to the reaction results, it is calculated that the conversion rate of isobutene is 88.5%, the conversion rate of 1-butene is 12.5%, and the conversion rate of cis-trans 2...

Embodiment 3

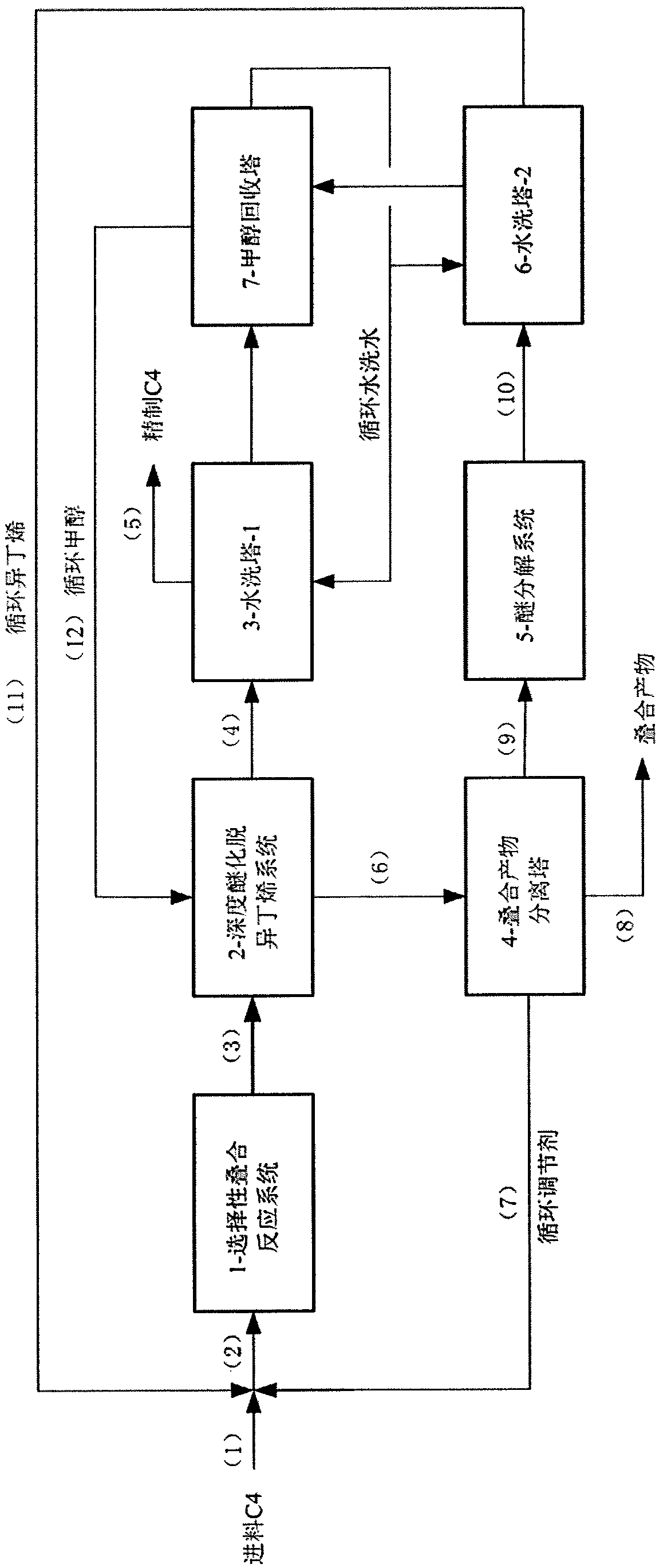

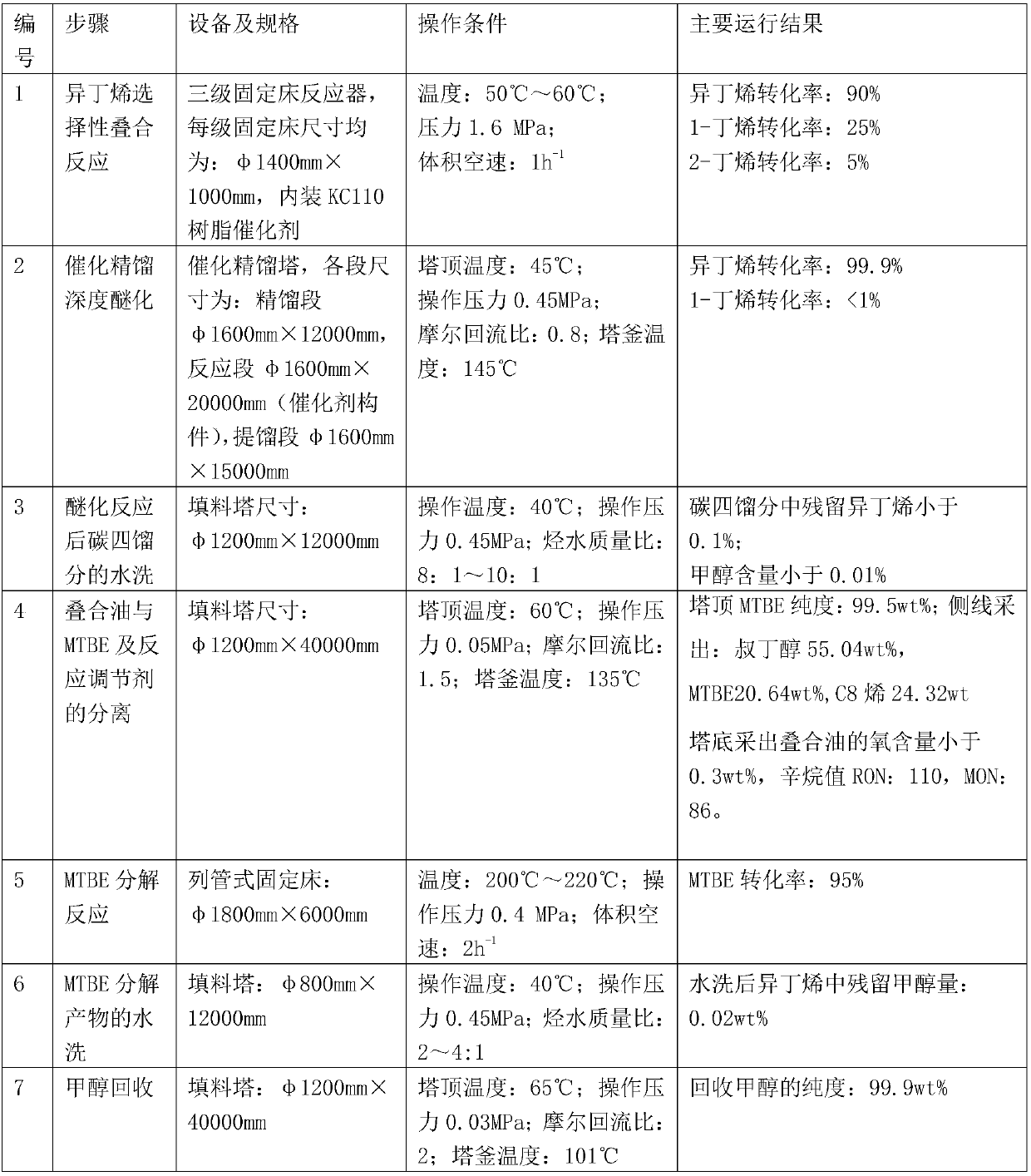

[0109] Attached figure 1 Shown technological process, set up the industrial test device of the present invention, the equipment specifications and operating conditions of each step are shown in Table 1.

[0110] Table 1 industrial experimental device of the present invention

[0111]

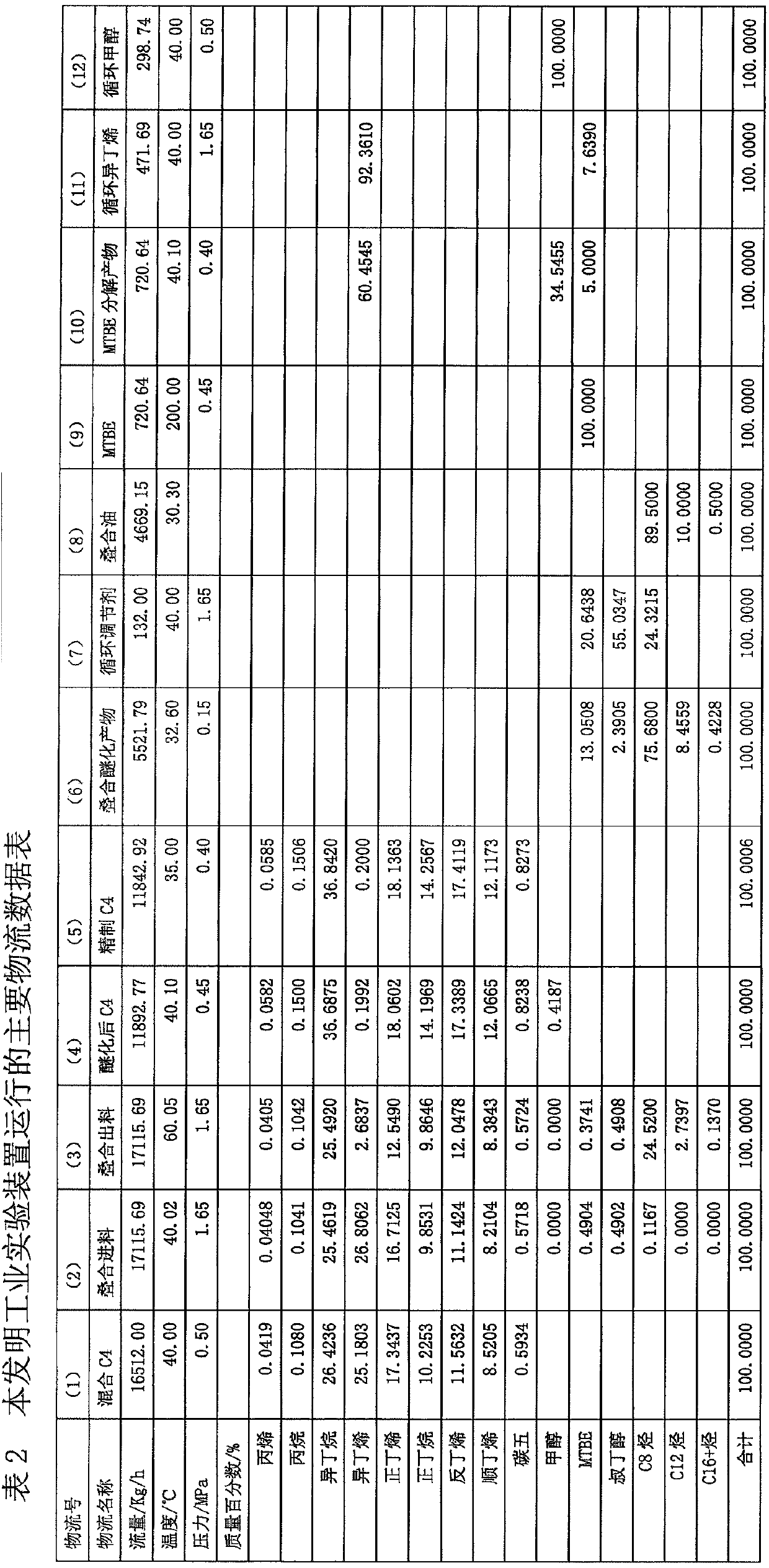

[0112] The main logistics data table 2 of the experimental device operation of the present invention.

[0113]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap