An anti-oxidation and low-wear steam turbine blade steel profile and its preparation process

A steam turbine blade, low-wear technology, applied in metal material coating process, polyurea/polyurethane coatings, anti-corrosion coatings, etc., can solve problems such as blade breakage, impact on unit safety and reliability, and grade efficiency decline, and achieve coating combination. Strong strength, improve fatigue resistance and physical and chemical properties, prolong use efficiency and life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

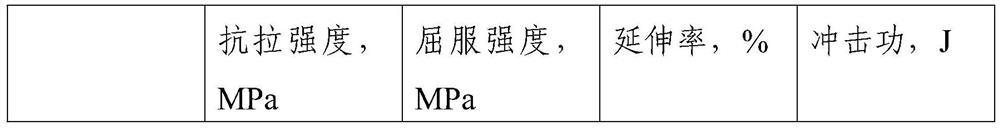

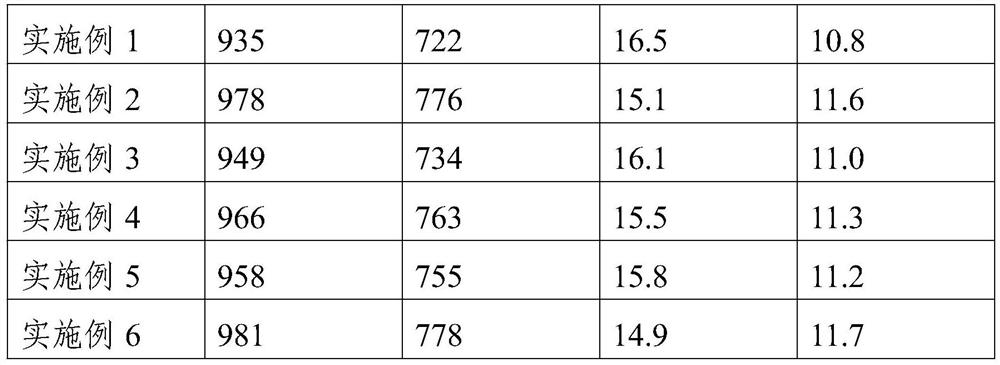

Examples

Embodiment 1

[0032] An anti-oxidation and low-wear steel profile for steam turbine blades, including a blade body and a multi-coating layer coated on the outer layer of the blade body in sequence, the multi-coating layer is a wear-resistant strengthening layer and a repairing protective layer, and the wear-resistant strengthening layer is Ni-Ti - Co-Si-Al-Cu coating, the repair protection layer is a rare earth-containing polyurethane-based coating. The wear-resistant reinforced layer is prepared by laser cladding, and the thickness of the wear-resistant reinforced layer is 1 mm; the repaired protective layer is prepared by dipping, and the thickness of the repaired protective layer is 3 mm.

[0033] The blade body includes the following mass percentage components: C 0.8%, Cr 9.4%, Ni0.7%, Mn 0.45%, Si 0.5%, W 0.8%, Co 1.2%, V≤0.2%, P≤0.03%, S≤0.03%, Fe balance.

[0034] The mass percent content of each component in the wear-resisting strengthening layer is: Ti 5%, Co 20%, Si 5%, Al 16%, C...

Embodiment 2

[0047] An anti-oxidation and low-wear steel profile for steam turbine blades, including a blade body and a multi-coating layer coated on the outer layer of the blade body in sequence, the multi-coating layer is a wear-resistant strengthening layer and a repairing protective layer, and the wear-resistant strengthening layer is Ni-Ti - Co-Si-Al-Cu coating, the repair protection layer is a rare earth-containing polyurethane-based coating. The wear-resistant strengthening layer is prepared by laser cladding, and the thickness of the wear-resistant strengthening layer is 3mm; the repairing protective layer is prepared by dipping, and the thickness of the repairing protective layer is 3mm.

[0048] The blade body includes the following mass percentage components: C 0.95%, Cr 9.5%, Ni0.6%, Mn 0.4%, Si 0.4%, W 1.0%, Co 1.4%, V≤0.2%, P≤0.03%, S≤0.03%, Fe balance.

[0049] The mass percent content of each component in the wear-resisting strengthening layer is: Ti 8%, Co 25%, Si 10%, Al...

Embodiment 3

[0062] An anti-oxidation and low-wear steel profile for steam turbine blades, including a blade body and multi-coatings sequentially coated on the outer layer of the blade body. layer, wear-resistant strengthening layer, the wear-resistant strengthening layer is a Ni-Ti-Co-Si-Al-Cu coating, and the repairing protection layer is a rare earth-containing polyurethane-based coating. The wear-resistant reinforced layer is prepared by laser cladding, and the thickness of the wear-resistant reinforced layer is 1 mm; the repaired protective layer is prepared by dipping, and the thickness of the repaired protective layer is 5 mm.

[0063] The blade body includes the following mass percentage components: C 0.9%, Cr 9.25%, Ni0.7%, Mn 0.35%, Si 0.4%, W 0.9%, Co 1.3%, V≤0.2%, P≤0.03%, S≤0.03%, Fe balance.

[0064] The mass percent content of each component in the wear-resisting strengthening layer is: Ti 3%, Co 15%, Si 6%, Al 20%, Cu 6%, and Ni balance.

[0065] The parts by weight of ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com