A kind of guide tube device and crystal pulling furnace

A technology of guide tube and guide wall, which is applied in the field of guide tube devices and crystal pulling furnaces, can solve the problems of high integrated circuit potential impact, crystal ingot quality, etc., to avoid void defects, improve crystal ingot quality, Suppresses the effect of supersaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

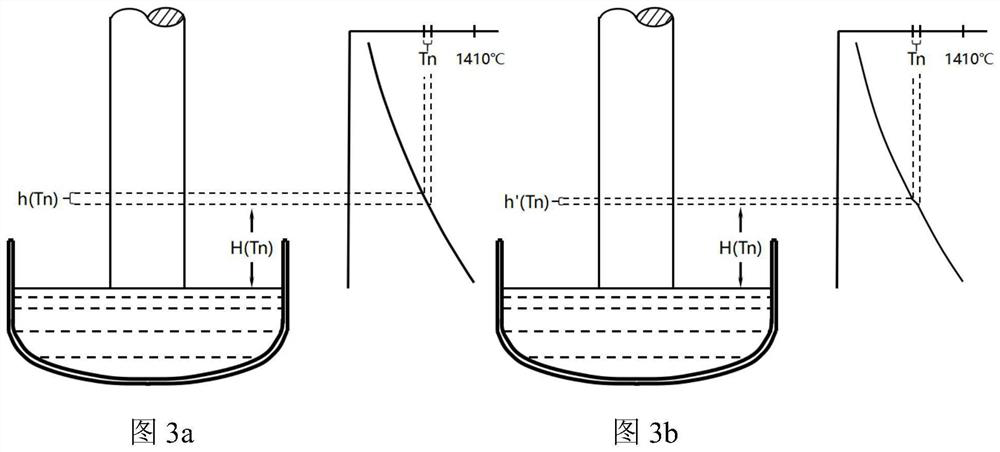

[0034] The formation of void-type defects usually goes through two processes. First, during the cooling process of the ingot, with the increase of the distance from the solid-liquid interface, the supersaturation of vacancies increases gradually. When the supersaturation reaches a certain value at a certain temperature, The vacancies aggregate to nucleate and then grow through vacancy diffusion. Since the migration rate of vacancies decreases with the decrease of the ingot temperature, the characteristic temperature range Tn for the rapid nucleation and growth of vacancy-type defects due to the aggregation reaction of vacancy-type intrinsic defects is approximately 1100-1070℃. Determines the size of the void-type defect. When the temperature is greater than Tn, the nucleation rate of void-type defects is very small; in the Tn temperature range, the nucleation rate of void-type defects is very large; when the ingot temperature is lower than Tn, the nucleation rate of void-type ...

Embodiment 2

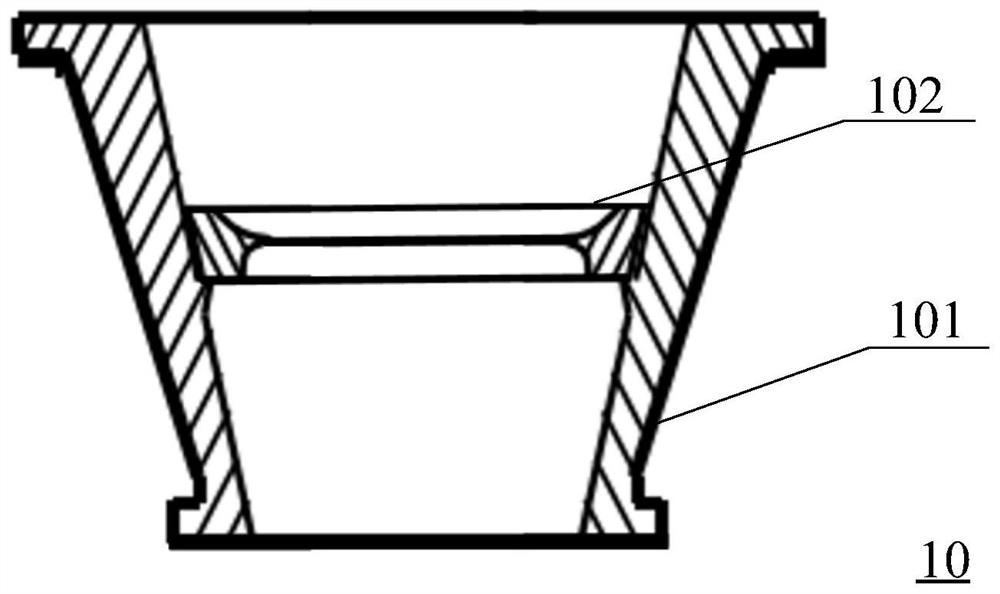

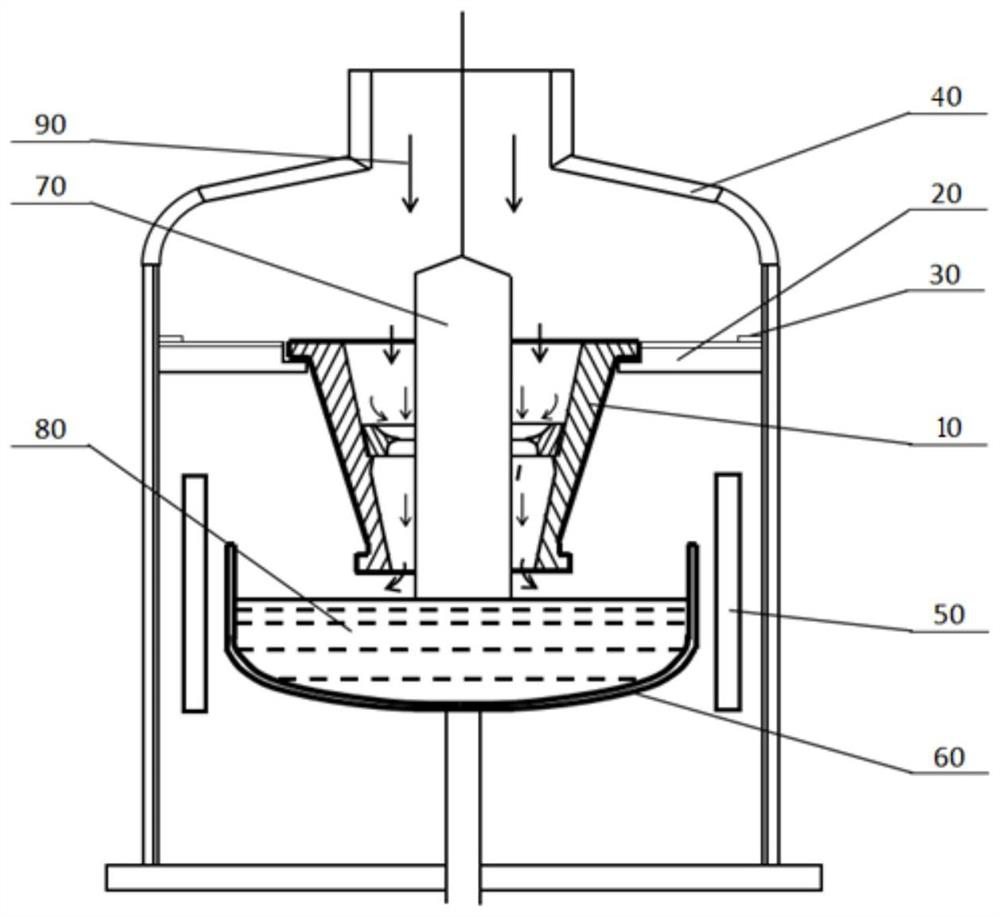

[0060] See figure 1 and figure 2 , this embodiment further provides a crystal pulling furnace on the basis of the above-mentioned embodiment. The crystal pulling furnace is used to manufacture the crystal rod 70, and includes: a furnace body 40, and the furnace body 40 includes a guide tube device 10 and a heat preservation cover 20. , pressure ring 30, heater 50, quartz crucible 60; furnace body 40 is fed with inert gas 90 from top to bottom; The design can make the inert gas 90 pass into the crystal pulling furnace from the auxiliary chamber. During the process of the inert gas 90 flowing from the ingot 70 to the melt 80, when it moves to the diameter reducing device 102 of the guide tube device 10, due to the airflow The channel becomes smaller, so that the flow rate of the inert gas 90 when flowing through the diameter reducing device 102 is increased, so that the ingot 70 at this height can be centrally cooled.

[0061] It should be understood that other devices of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com