Gas-liquid separation assembly, alkali liquor regeneration tower and alkali liquor regeneration method

A technology of gas-liquid separation and regeneration tower, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc. It can solve problems such as corrosion of sulfur dioxide in transportation pipelines, environmental problems that plague enterprises, and poor separation effects. It is easy to implement, Improve the efficiency of gas-liquid separation and the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

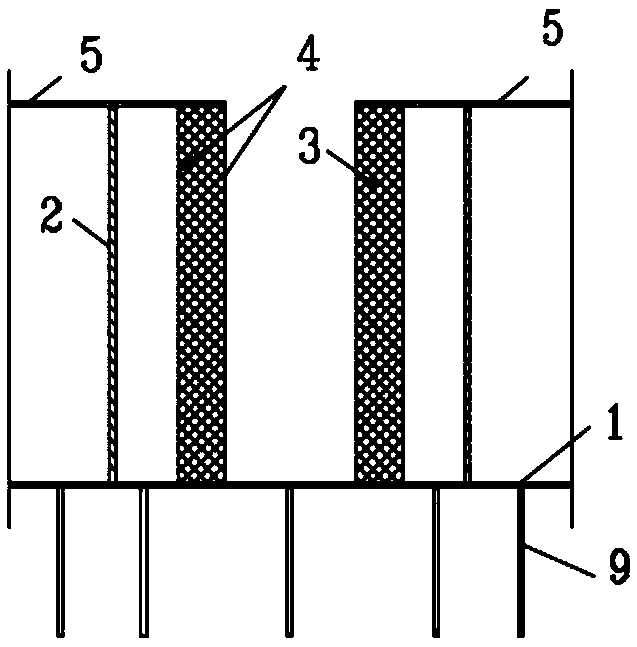

[0054] This embodiment adopts as Image 6 As shown in the lye regeneration tower, the tower body specification is the same as that of the comparative example, and the chimney baffle plate 17 is removed in the tower top space and installed Figure 1 to Figure 5 The gas-liquid separation assembly shown.

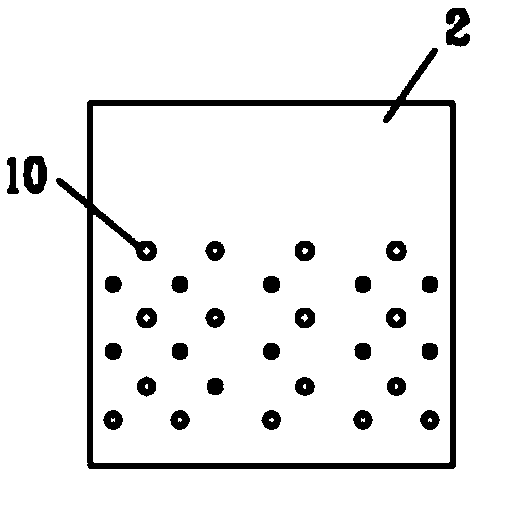

[0055]The device for reducing the sulfur content of alkali liquor regeneration tail gas comprises a base plate 1, a baffle plate 2, a wire mesh pad 3, a support structure 4 and a top plate 5; wherein, a plurality of first through holes are respectively distributed at both ends of the base plate 1, and the The edge is sealed with the inner wall of the alkali liquor regeneration tower, and two baffles are vertically fixed between the bottom plate 1 and the top plate 5 to form two gas inlet areas with the first through hole 7 in the middle of the bottom plate 1 and the top plate 5 and are located in the middle In the distribution area, the diameter of the first through hole 7 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com