High-strength anti-crack concrete and preparation process thereof

A high-strength, concrete technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as concrete cracking and concrete cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

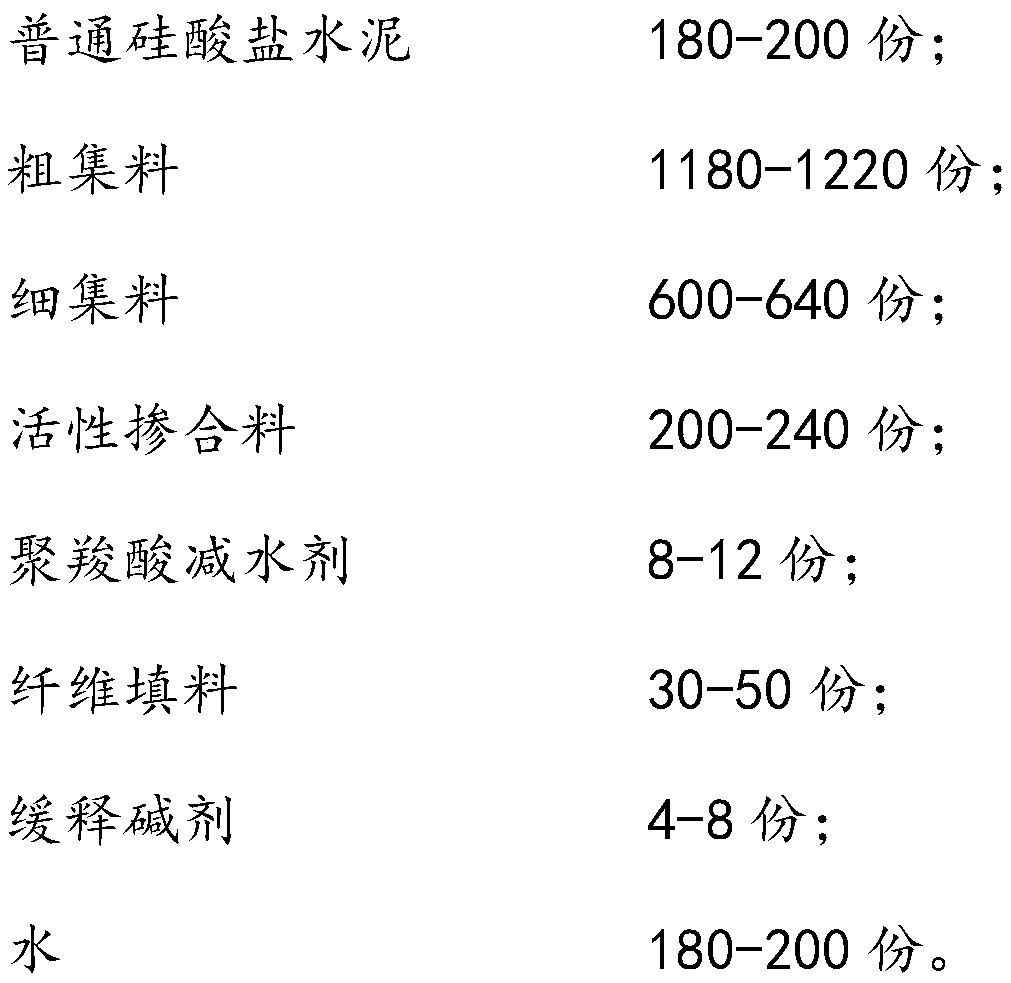

Method used

Image

Examples

Embodiment 1

[0052] The invention discloses a preparation process of high-strength crack-resistant concrete, which comprises the following process steps:

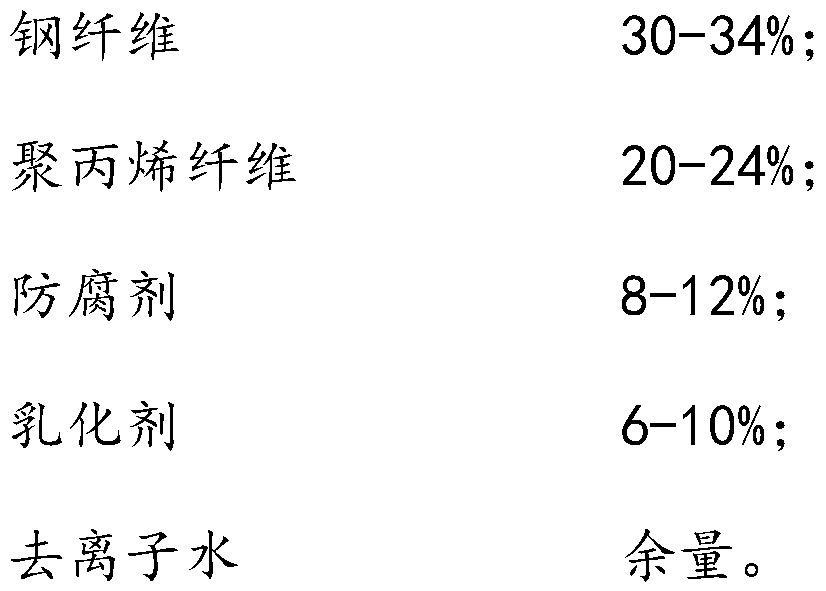

[0053] 1) Prepare the fiber filler, including the following preparation steps: by weight percentage, first mix 28% deionized water and 8% emulsifier evenly, then add 32% steel fiber and 22% polypropylene fiber, stir evenly Finally, add preservative and mix evenly to obtain fiber filler;

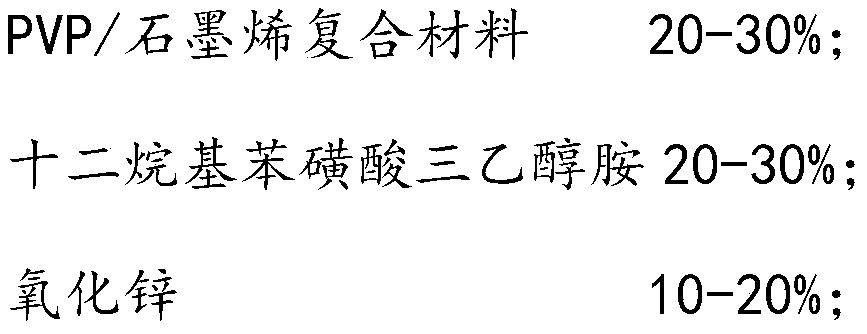

[0054] Wherein, the preservative comprises the following preparation steps: by weight percentage, first mix 25% triethanolamine dodecylbenzenesulfonate, 15% zinc oxide, 15% sodium monofluorophosphate and 20% deionized water uniform, and then add 25% PVP / graphene composite material and stir evenly to obtain a preservative;

[0055] Wherein, the emulsifier comprises the following raw materials in weight percent:

[0056] OP-40 emulsifier 25%;

[0057] Sodium Lauryl Sulfonate 45%;

[0058] GR-200 paraffin emulsifier 30%;

[0059] 2) Prepare the slow-...

Embodiment 1

[0071] The difference between embodiments 10-13 and embodiment 1 is that the preservative comprises the following raw materials in percentage by weight:

[0072]

[0073] The difference between Embodiment 14-17 and Embodiment 1 is that the emulsifier comprises the following raw materials in weight percent:

[0074]

[0075] The difference between Embodiment 18-21 and Embodiment 1 is that the slow-release alkali agent comprises the following raw materials in weight percentage:

[0076]

[0077] The difference between embodiment 22-25 and embodiment 1 is that the basic conditioner comprises the following raw materials in weight percent:

[0078]

[0079] The difference between embodiment 26-29 and embodiment 1 is that the active admixture comprises the following raw materials in weight percent:

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com