Power catwalk machine capable of feeding and throwing three drilling and exploitation tubular columns

A catwalk machine and pipe string technology, which is applied in the direction of drill pipe, earthwork drilling, drill pipe, etc., can solve the problems that affect the drilling and production progress, long working hours, and long time for throwing the pipe string, so as to improve the drilling efficiency, High efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

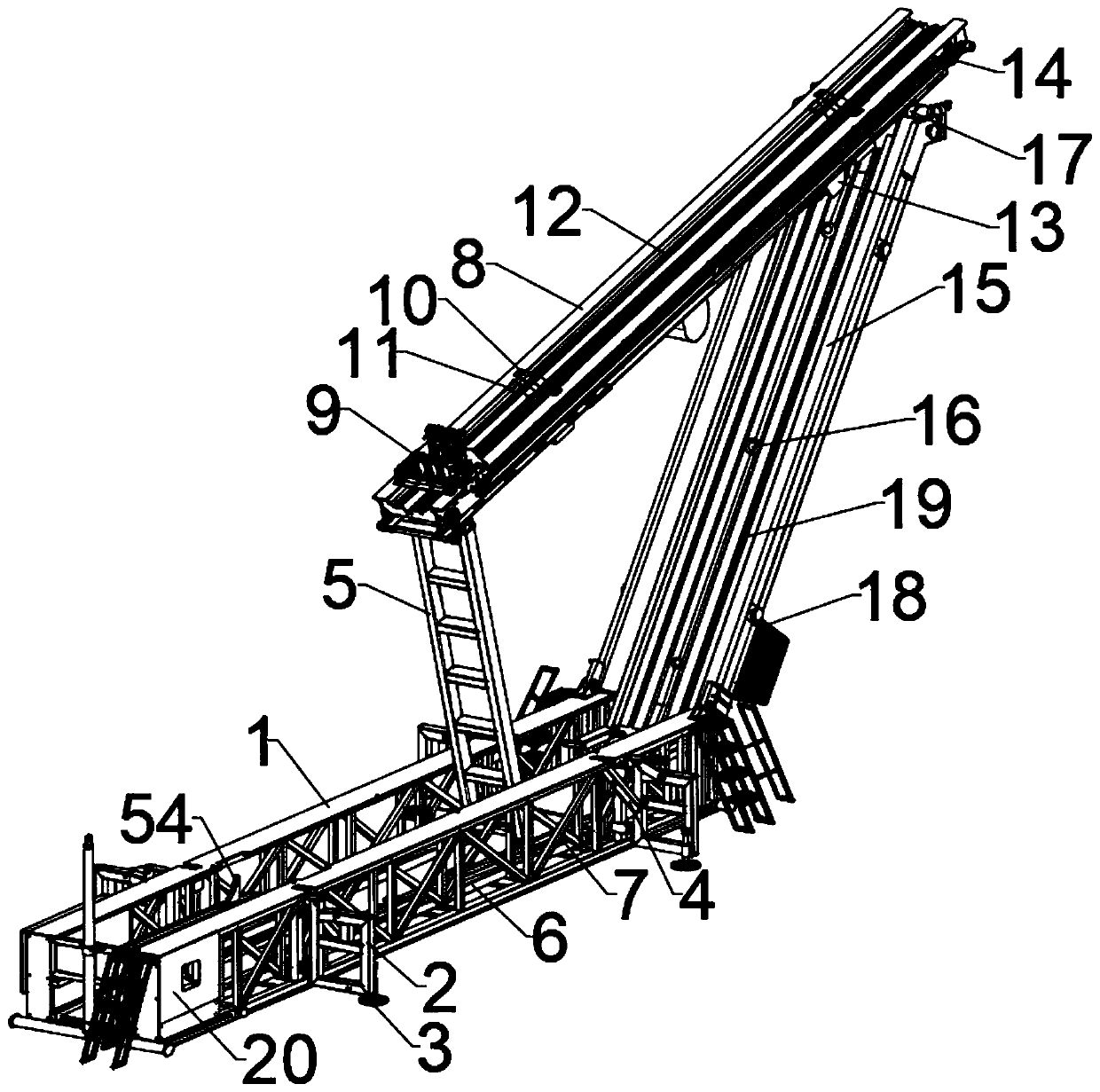

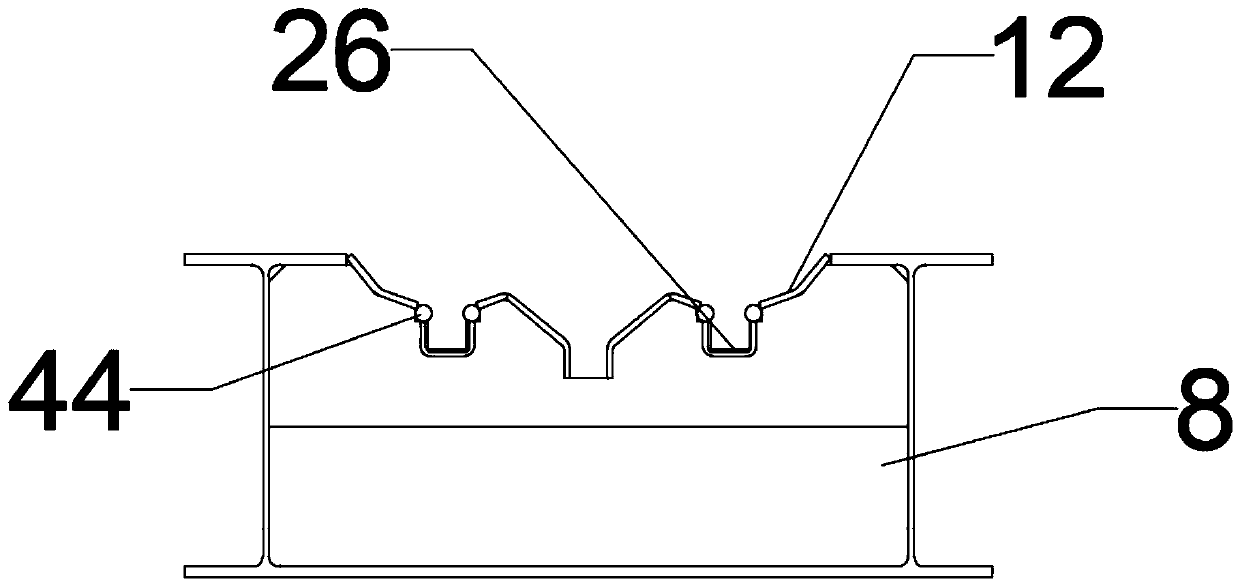

[0049] Such as Figure 1-Figure 13 As shown, this embodiment provides a power catwalk machine for sending and throwing three drilling and production strings, including: a base frame 1, a support arm 5, a ramp 15, a sliding arm 8, a pulley assembly 9 and a sliding arm hydraulic winch.

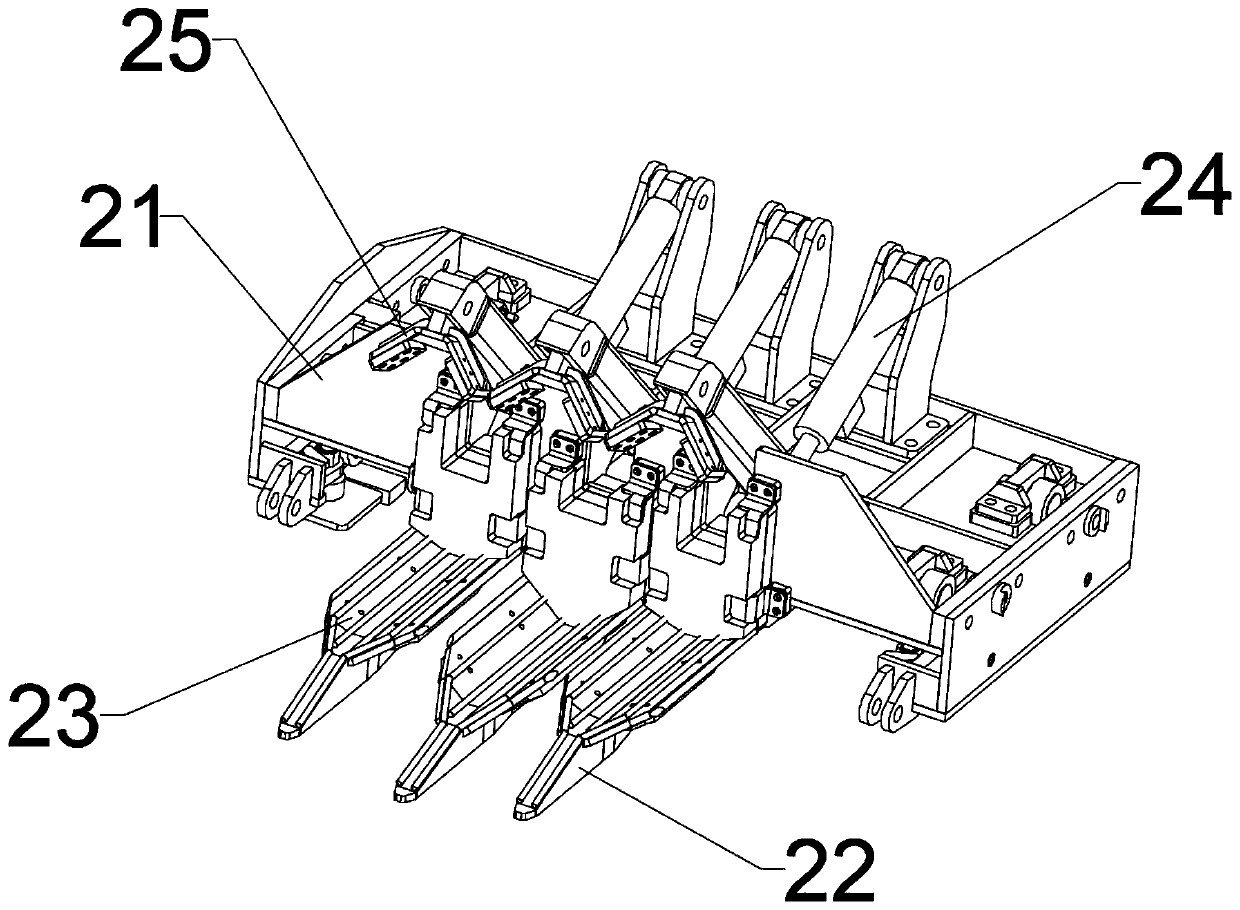

[0050] The base frame 1 is horizontally arranged, the base frame 1 is a rectangle, the base frame 1 is provided with a placement groove, the placement groove is provided with a support arm sliding track, the both sides of the base frame 1 are provided with a pipe picking device 4, and the pipe picking device 4 can The pipe column on the row pipe is picked in the sliding arm 8. One end of support arm 5 is slidably connected on the support arm slide track, and is hinged with the support arm slide track, wherein support arm 5 is slidably connected on the support arm slide track by support arm 5 roller sets, and one end of support arm 5 is connected with support arm 5 The roller group is hinged by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com