Liquid injection mode of nickel battery and nickel battery

A nickel battery and liquid injection technology, which is applied to nickel storage batteries, alkaline storage batteries, battery pack components, etc., can solve problems such as richness and nickel battery drying up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Example 1 provides a nickel-metal hydride battery, which is basically prepared in the same way as the existing 50AA2700 ultra-high-capacity nickel-hydrogen battery, except that OH is injected first - 2.40g of electrolyte solution with an ion concentration of 10mol / L and a water content of 66%, additionally fill the center hole with a gel formed by 1wt% xanthan gum + 1wt% sodium polyacrylate, the OH of the filled gel - The ion concentration is 9mol / L, the water content is 69%, the center hole is filled, and the gel filling amount is 0.18g.

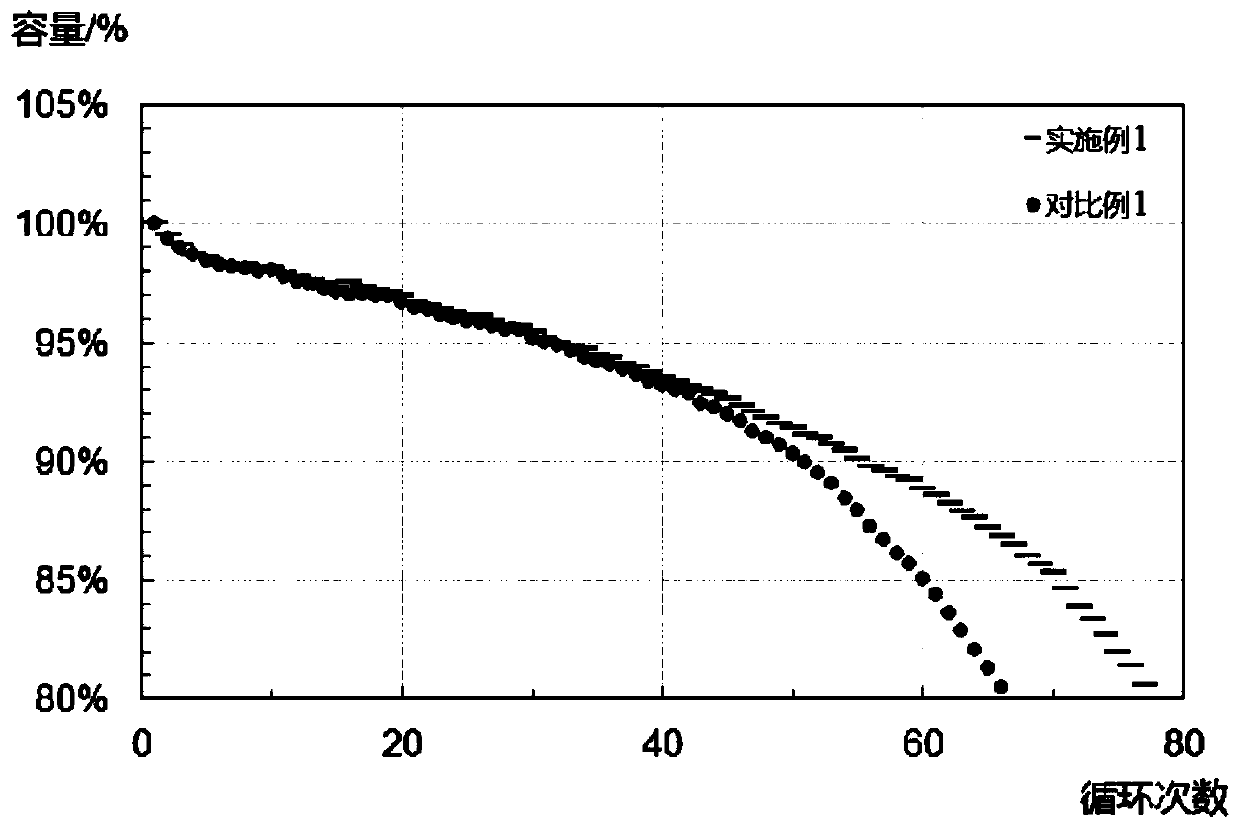

[0033] Take the Ni-MH batteries of Comparative Example 1 and Example 1 respectively, and the comparison diagram of the two in 1C cycle life is as follows figure 1 As shown, the total amount of solvent in Comparative Example 1, i.e. the total amount of water, is 1.58g (2.40g×66%=1.58g), and the total amount of water in Example 1 is 1.70g (2.40g×66%+0.18g×69%=1.70 g), which is equivalent to injecting 0.12g more pure water, ...

Embodiment 2

[0036] Embodiment 2: Embodiment 2 provides a nickel-hydrogen battery, which is basically the same as the existing 50AA2200 ultra-low-cost nickel-hydrogen battery. The difference is that OH is injected first - The ion concentration is 12mol / L, the electrolyte solution 2.80g that water content is 61.5%, the gel that additionally fills 3wt% sodium polyacrylate in the center hole, the OH of the filled gel - The ion concentration is 12mol / L, the water content is 60.5%, the center hole is filled, and the gel filling amount is 0.60g.

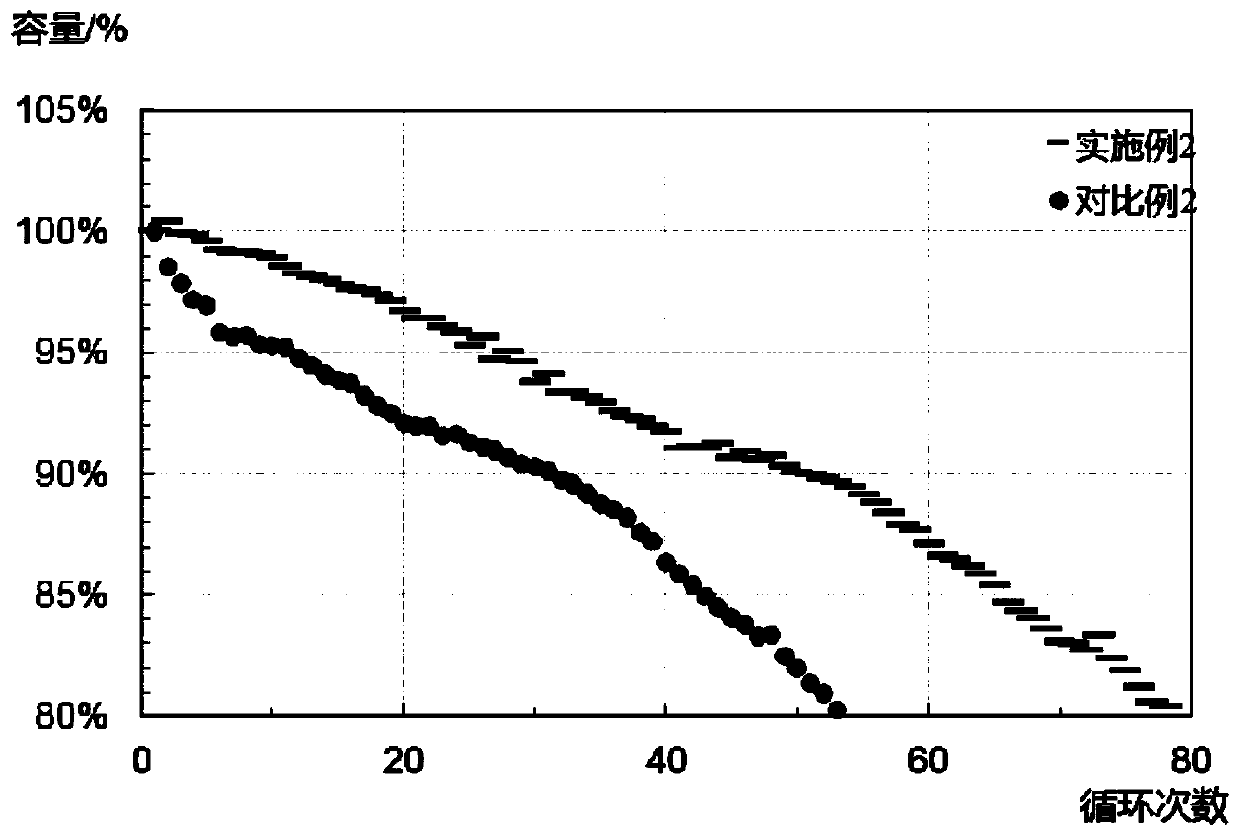

[0037] Take the Ni-MH batteries of Comparative Example 2 and Example 2 respectively, and the comparison diagram of the two in 1C cycle life is as follows: figure 2 As shown, the total amount of solvent in Comparative Example 1, i.e. the total amount of water, is 1.78g (2.90g×61.5%=1.78g), and the total amount of water in Example 1 is 2.09g (2.80g×61.5%+0.6g×60.5%=2.09 g), which is equivalent to adding 0.31g of pure water, which is an increase of 17%....

Embodiment 3

[0040] Embodiment 3: Embodiment 3 provides a nickel-hydrogen battery, which is basically the same as the existing 50AA1300 long-life nickel-hydrogen battery. The difference is that the OH is injected first - 2.60g of electrolyte solution with an ion concentration of 7.5mol / L and a water content of 69%, and additionally fill the center hole with 1wt% Yb(OH) 3 +0.5wt% agarose formed gel, OH of the filled gel- The ion concentration is 7.3mol / L, the water content is 68.5%, the center hole is filled, and the gel filling amount is 0.70g.

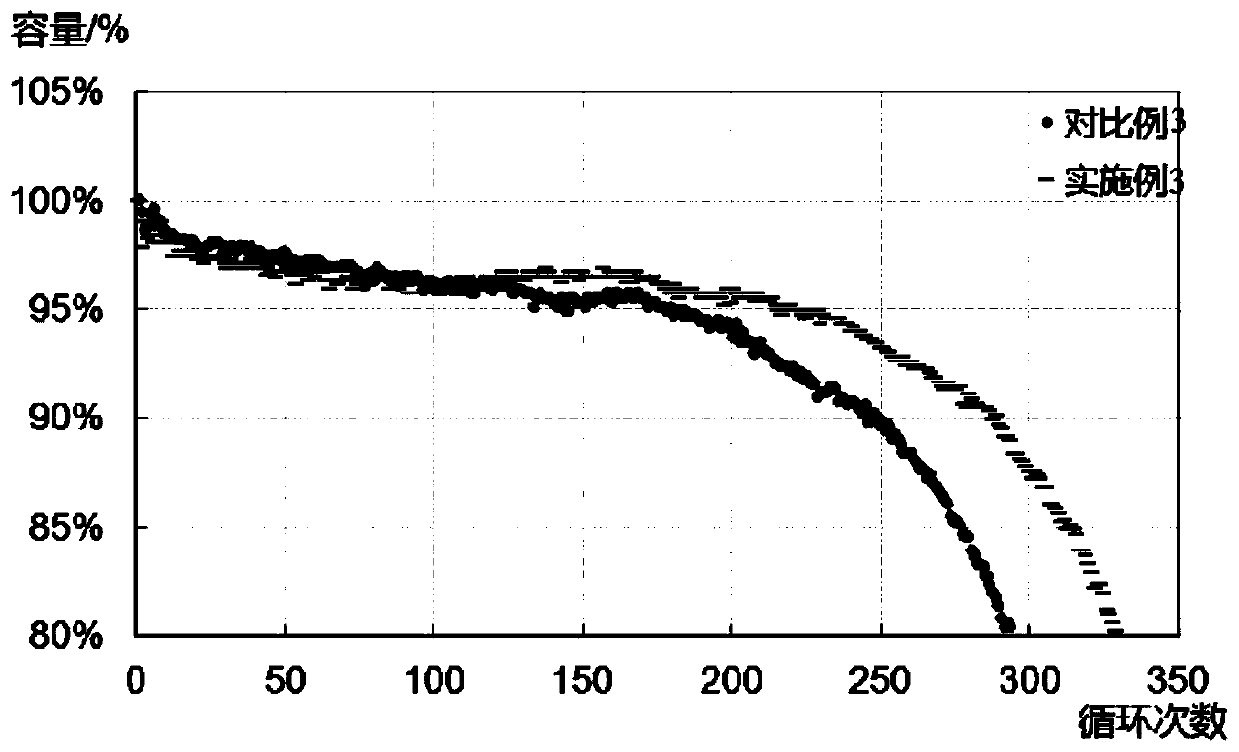

[0041] Take the Ni-MH batteries of Comparative Example 3 and Example 3 respectively, and the comparison chart of the two at 10A cycle life is as follows: image 3 As shown, the total amount of solvent in Comparative Example 3, i.e. the total amount of water, is 1.90g (2.75g×69%=1.90g), and the total amount of water in Example 3 is 2.27g (2.60g×69%+0.7g×68.5%=2.27 g), which is equivalent to adding 0.37g of pure water, which is an increase of 19.5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com