Polarizing plate, polarizing plate roll, and method for producing polarizing film

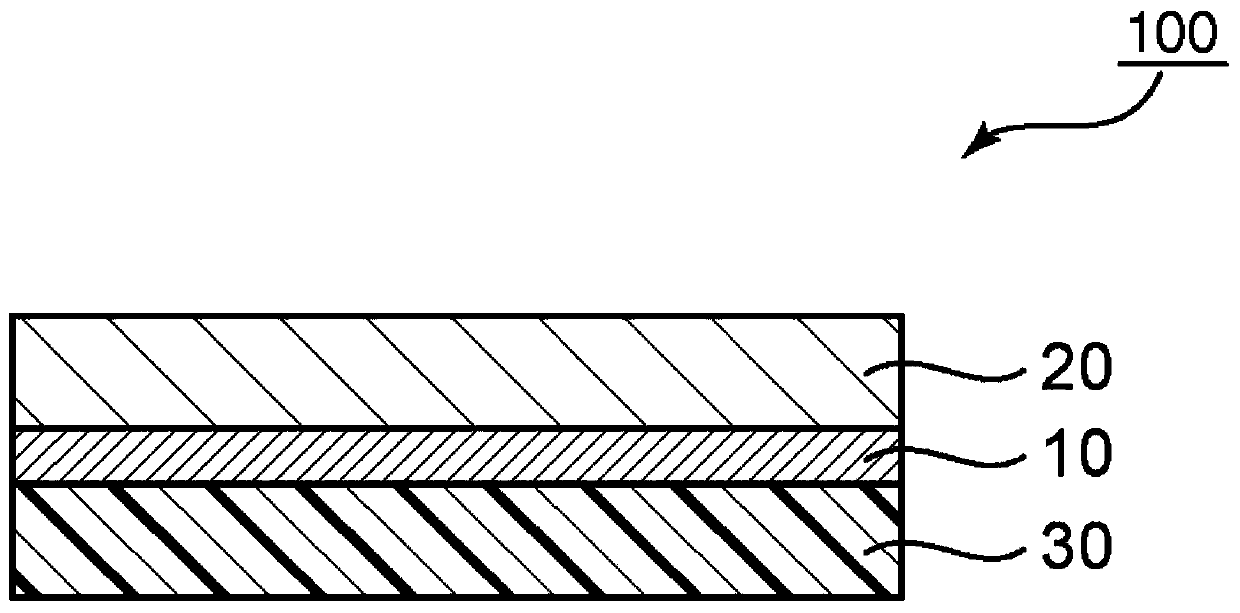

A manufacturing method and polarizing film technology, applied in polarizing elements, flat products, applications, etc., can solve problems such as insufficient optical properties of thin polarizing films, and achieve excellent optical properties and deviation suppression effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

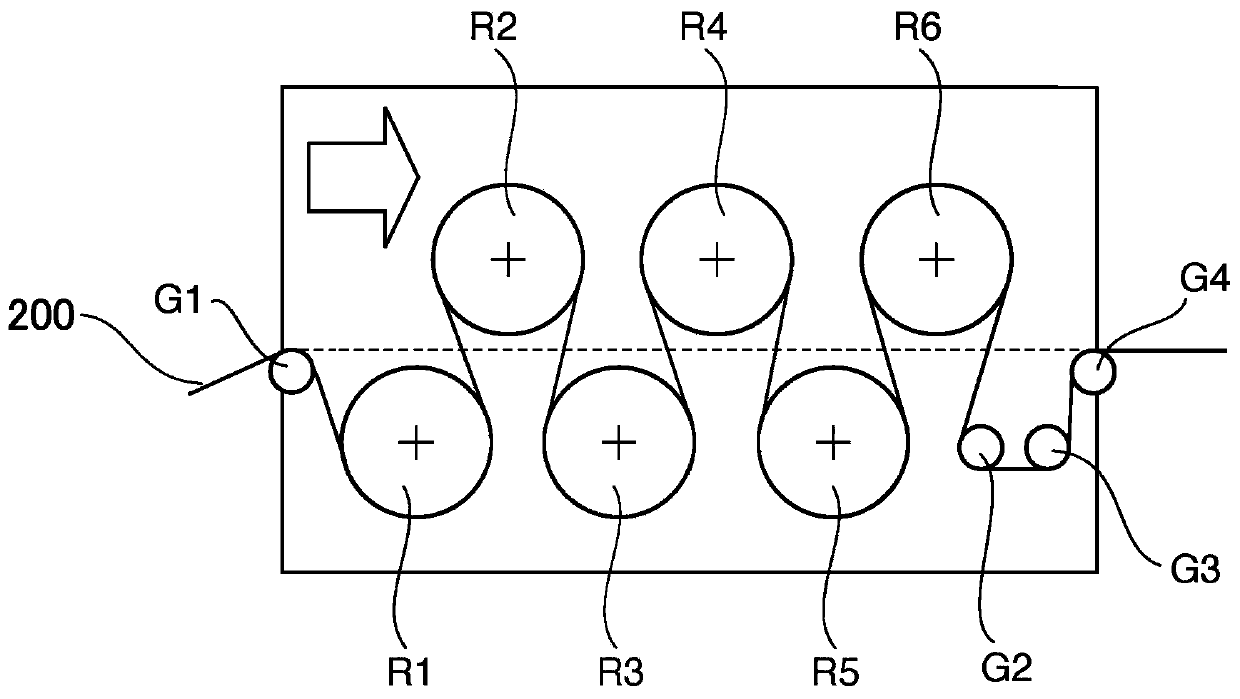

Method used

Image

Examples

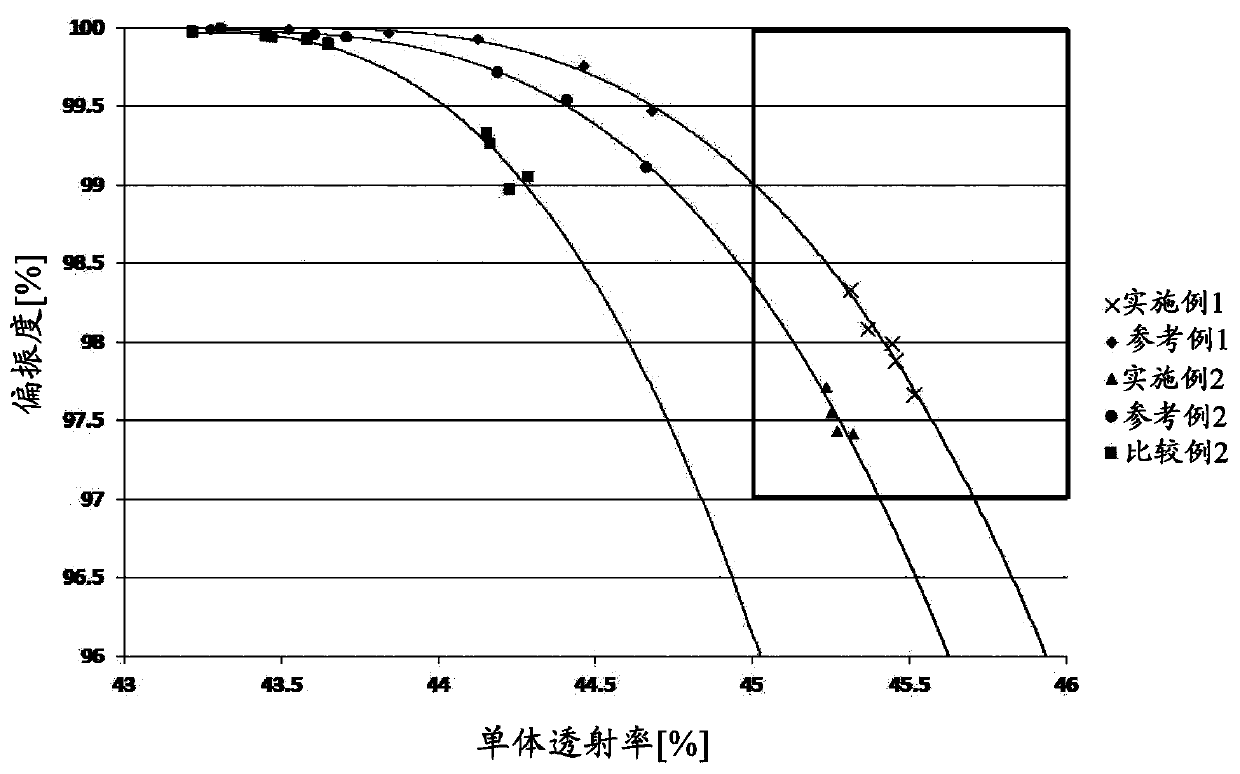

Embodiment 1

[0122] 1. Fabrication of polarizing film

[0123] As the thermoplastic resin substrate, a long amorphous isophthalic acid-copolymerized polyethylene terephthalate film (thickness: 100 μm) having a water absorption rate of 0.75% and a Tg of about 75° C. was used. Corona treatment was performed on one side of the resin substrate.

[0124] PVA-based resin made by mixing polyvinyl alcohol (polymerization degree 4200, saponification degree 99.2 mol%) and acetoacetyl-modified PVA (manufactured by Nippon Synthetic Chemical Industry Co., Ltd., trade name "GOHSEFIMER Z410") at a ratio of 9:1 To 100 parts by weight, 13 parts by weight of potassium iodide was added to prepare an aqueous PVA solution (coating solution).

[0125] The above-mentioned PVA aqueous solution was applied on the corona-treated surface of the resin substrate, and dried at 60° C. to form a PVA-based resin layer with a thickness of 13 μm, thereby producing a laminate.

[0126] The free end of the obtained laminate...

reference example 1

[0137] Six polarizing films and polarizing plates were produced in the same manner as in Example 1 except that dyeing treatment was performed so that the single-body transmittance (Ts) of the finally obtained polarizing film became 43% or more and less than 45%.

Embodiment 2

[0139] Four polarizing films and polarizing plates were produced in the same manner as in Example 1 except that the oven temperature was 70° C. and the heating roll temperature was 70° C. in the drying shrinkage process. The shrinkage rate of the laminated body in the width direction due to the drying shrinkage treatment was 2.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap