Functional combined formula milk powder capable of increasing bone density and enhancing human immunity, and production process thereof

A technology to increase bone density and formula milk powder, applied in milk preparations, dairy products, applications, etc., can solve problems such as insufficient synthesis, achieve the effects of inhibiting calcium loss, promoting calcium absorption, and enhancing body immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

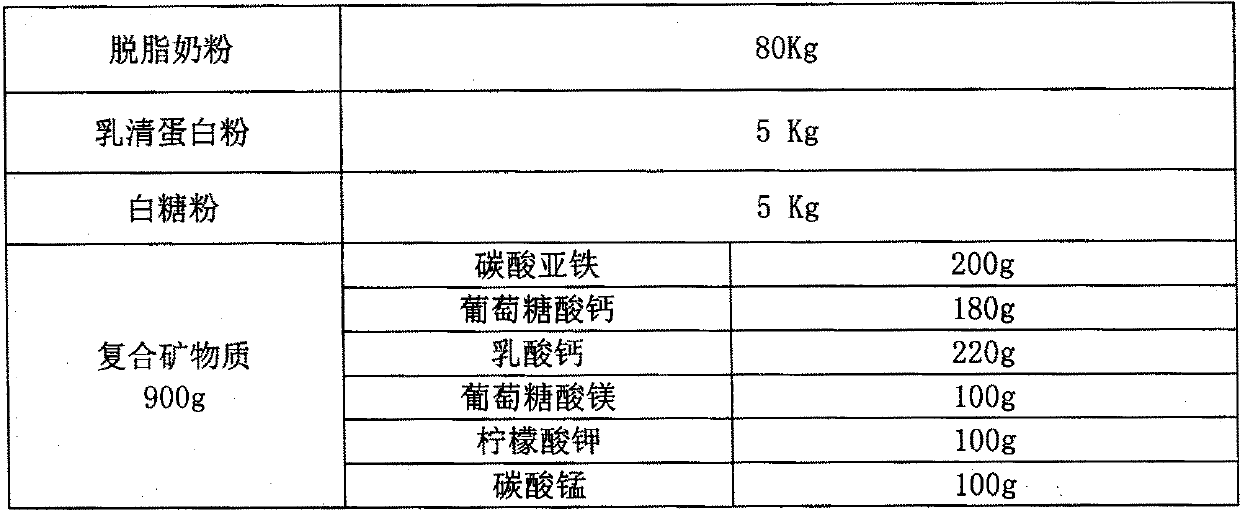

Embodiment 1

[0031]

[0032]

[0033] Preparation Process:

[0034] (1) Put 10 kg of skimmed milk powder into the three-dimensional mixer, and then add the weighed mineral component raw materials, vitamin component raw materials, zinc enhancer component raw materials, selenium enhancer component raw materials, and other formula milk powders to allow addition The nutrient component raw materials are poured into a three-dimensional mixer for primary premixing, and the premixing time is 6 minutes.

[0035] (2) Add 20 kg of skimmed milk powder, 5 kg of whey protein powder, and 5 kg of white sugar powder to the three-dimensional mixer for the second-stage pre-mixing, and the pre-mixing time is 6 minutes.

[0036] (3) Put the second-stage premixed material into a high-speed mixer, add 50 kg of skim milk powder at the same time, and perform three-stage mixing at a speed of 35-45 rpm and a mixing time of 5 minutes.

[0037] After the mixed product passes through a 40-mesh sieve, it is trans...

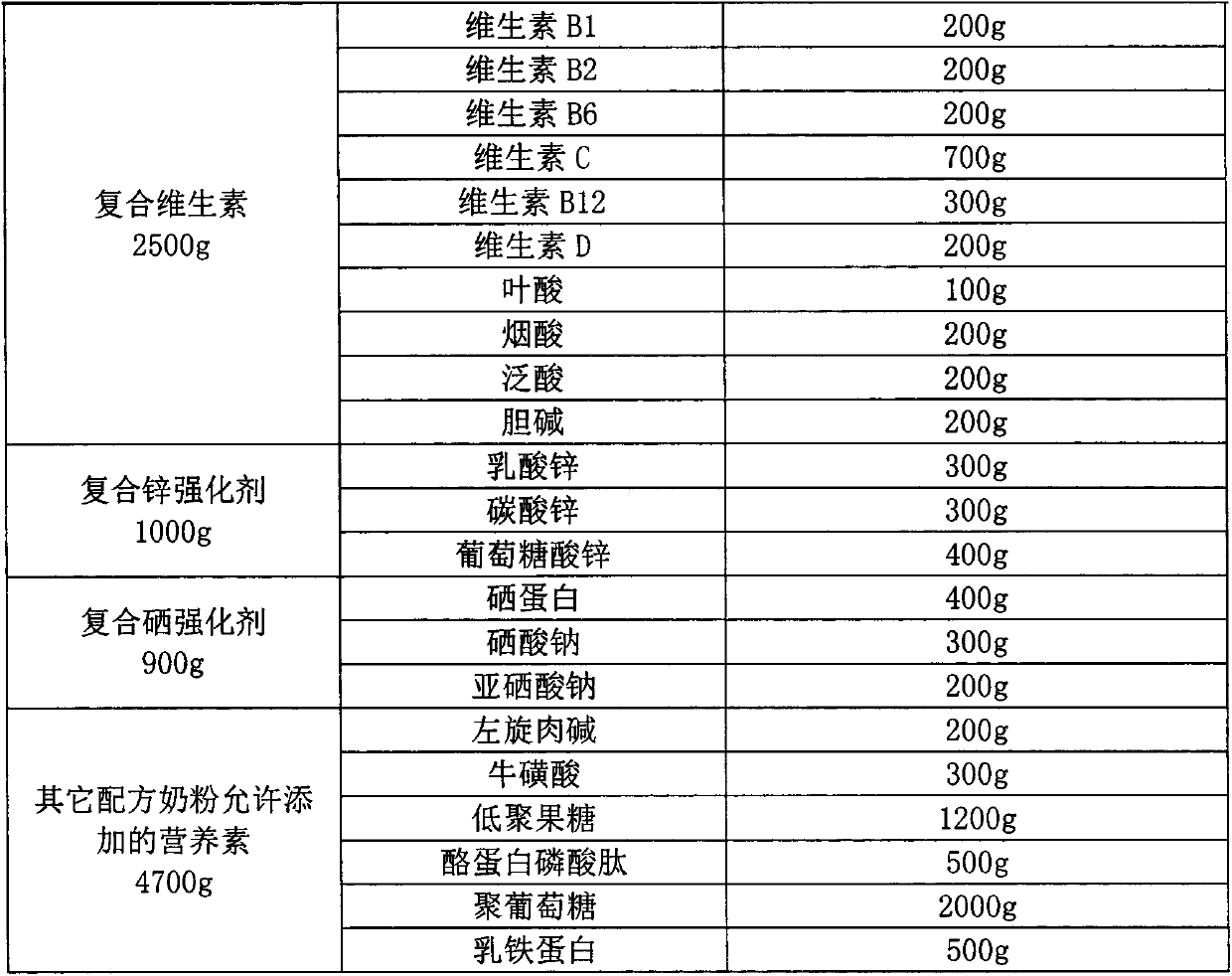

Embodiment 2

[0039]

[0040] Preparation Process:

[0041] (1) Put 15 kg of skimmed milk powder into the three-dimensional mixer, and then add the weighed mineral component raw materials, vitamin component raw materials, zinc enhancer component raw materials, selenium enhancer component raw materials, and other formula milk powders to allow addition The nutrient component raw materials are poured into a three-dimensional mixer for primary premixing, and the premixing time is 6 minutes.

[0042] (2) Add 20 kg of skimmed milk powder, 6 kg of whey protein powder, and 7 kg of white sugar powder to the three-dimensional mixer for the second-stage pre-mixing, and the pre-mixing time is 6 minutes.

[0043] (3) Put the second-stage premixed material into a high-speed mixer, add 47 kg of skim milk powder at the same time, and perform three-stage mixing with a rotating speed of 35-45 rpm and a mixing time of 5 minutes.

[0044] After the mixed product passes through a 40-mesh sieve, it is transf...

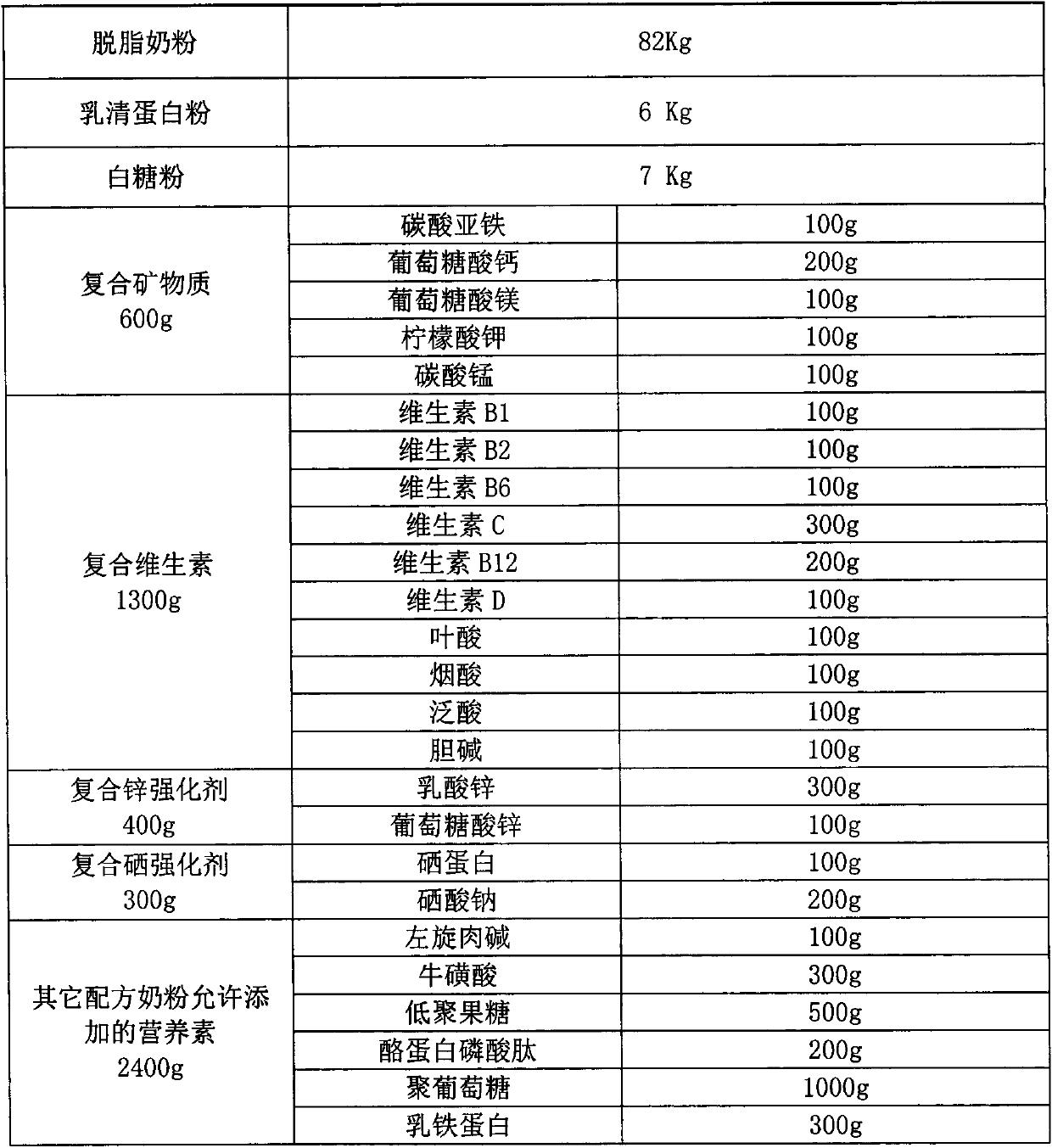

Embodiment 3

[0046]

[0047] Preparation Process:

[0048](1) Put 15 kg of skimmed milk powder into the three-dimensional mixer, and then add the weighed mineral component raw materials, vitamin component raw materials, zinc enhancer component raw materials, selenium enhancer component raw materials, and other formula milk powders to allow addition The nutrient component raw materials are poured into a three-dimensional mixer for primary premixing, and the premixing time is 6 minutes.

[0049] (2) Add 20 kg of skimmed milk powder, 5 kg of whey protein powder, and 5 kg of white sugar powder to the three-dimensional mixer for the second-stage pre-mixing, and the pre-mixing time is 6 minutes.

[0050] (3) Put the second-stage premixed material into a high-speed mixer, add 50 kg of skim milk powder at the same time, and perform three-stage mixing at a speed of 35-45 rpm and a mixing time of 5 minutes.

[0051] After the mixed product passes through a 40-mesh sieve, it is transferred to a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com