Method and device for removing SOx and NOx in catalytic cracking flue gas

A catalytic cracking and flue gas technology, applied in the field of flue gas purification, can solve the problems of waste water or waste residue, difficulty in continuous operation, and further improvement of removal rate, so as to avoid the influence of side reactions and reduce the risk of escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0054] According to a specific embodiment of the present invention, the method further includes degassing the regenerated adsorbent, and then feeding the adsorbent into the inlet of the riser reactor, and returning the obtained gas to the regeneration reactor.

[0055] In the present invention, the type of reducing gas used in step b) is not particularly limited, and may be various reducing gases conventionally used in the art. Preferably, the reducing gas is selected from H 2 , NH 3 , CO, CH 4 and at least one of light hydrocarbons with 2-4 carbon atoms, more preferably NH 3 .

Embodiment approach

[0056] According to a specific embodiment of the present invention, the reducing gas can be carried by a carrier gas and contacted with the catalytic cracking flue gas after SOx removal and a catalyst to perform a selective reduction reaction. The carrier gas can be air.

[0057] According to the present invention, preferably, the amount of the reducing gas used is 0.7-1.5 times, more preferably 0.9-1.1 times, the theoretical amount required for the reaction between the reducing gas and NOx. The required theoretical dosage refers to the theoretical stoichiometric value required for the reaction between the reducing gas and NOx. The reducing gas is NH 3 , NOx is NO as an example, NH 3 react with NO in the presence of a catalyst to form N 2 and H 2 O, NH required for 3 moles of NO 3 The theoretical dosage is 2 moles.

[0058] According to the present invention, the selection of the catalyst is not particularly limited, and may be a catalyst commonly used in the art for sel...

Embodiment approach A

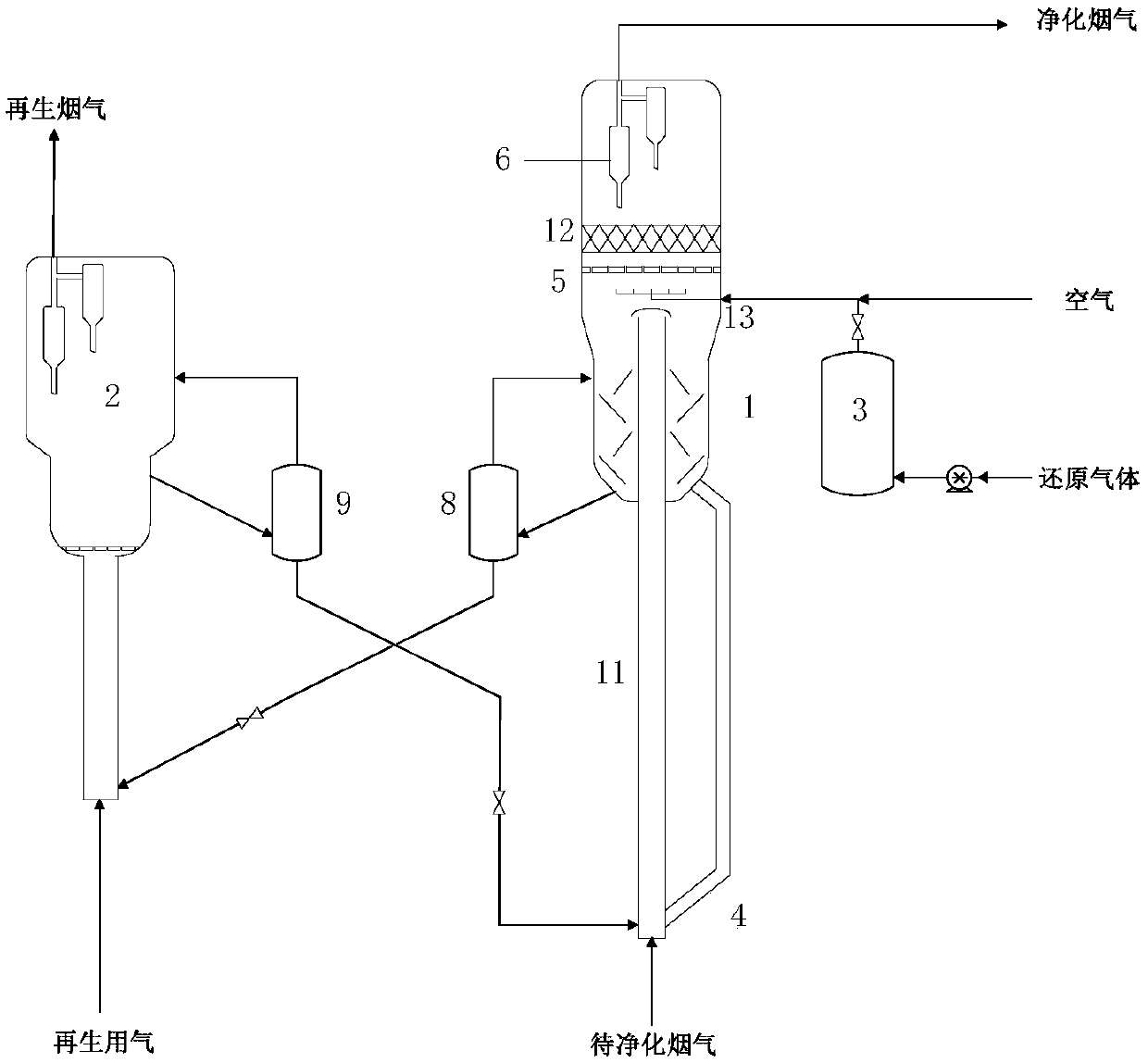

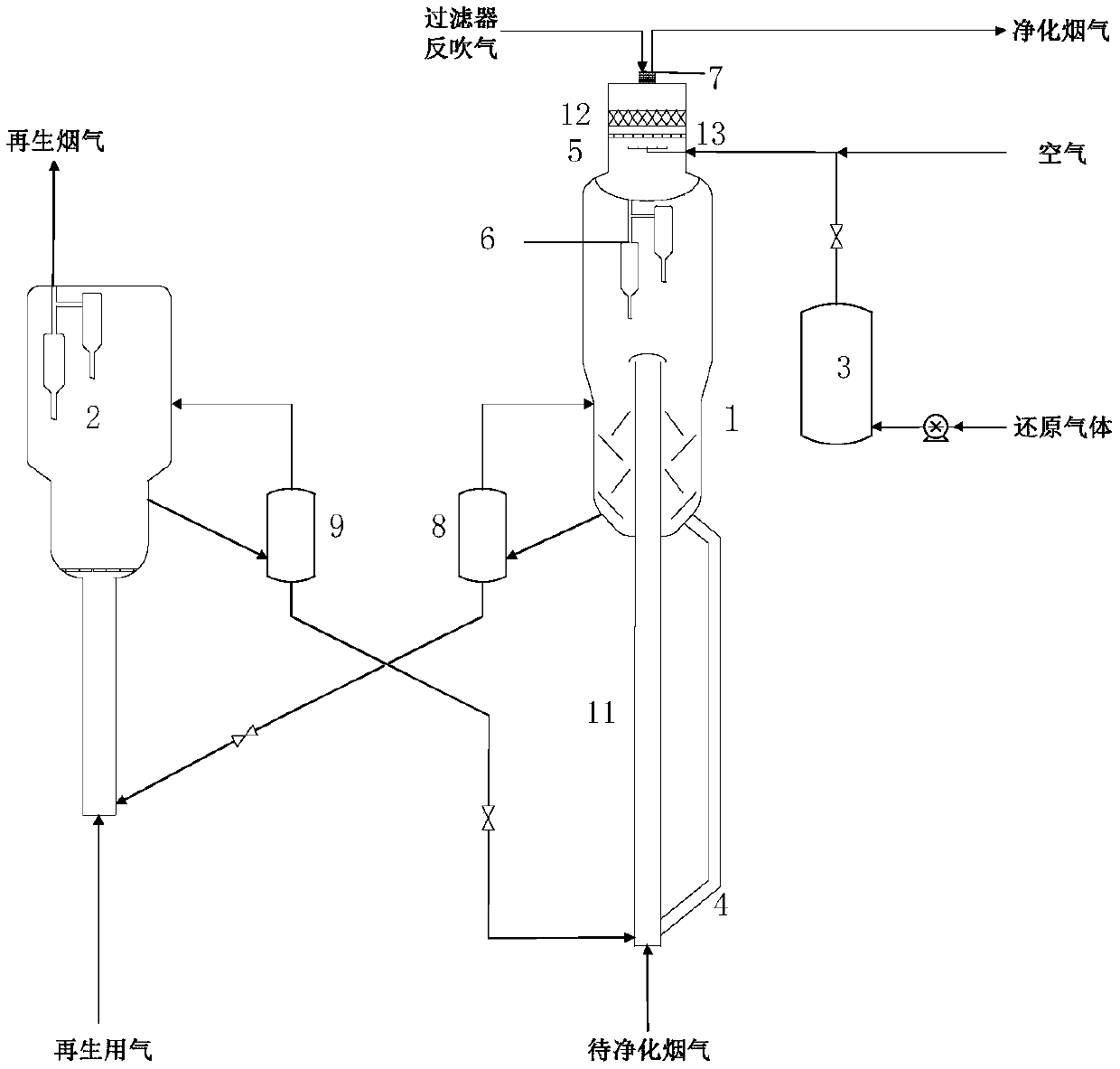

[0081] According to a preferred embodiment A of the present invention, the purification reactor 1 is also provided with a first gas-solid separation device 6, and the first gas-solid separation device 6 is arranged above the catalyst bed 12, more preferably arranged on The top of Reactor 1 was purged. The first gas-solid separation device 6 can prevent the adsorbent and catalyst fine powder carried in the flue gas from being discharged. The purified flue gas obtained by gas-solid separation meets the emission standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com