A preparation method of coating liquid for forming a thermosensitive recording layer

A technology of thermal recording and coating liquid, applied in the directions of thermal coating, temperature recording method, copy/marking method, etc. Excellent stability and good imaging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

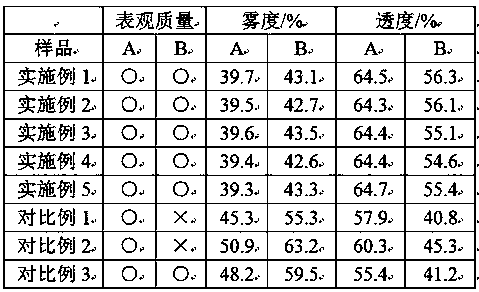

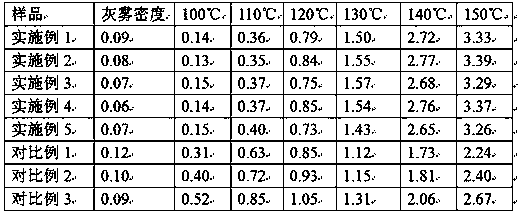

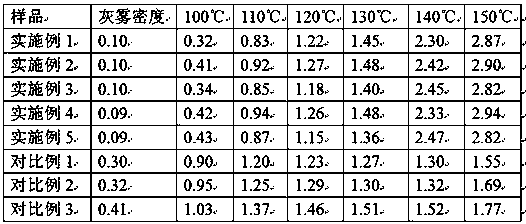

Examples

Embodiment 1

[0046] The coating solution for forming a thermosensitive recording layer is obtained by the following preparation method:

[0047] 1) Under slow stirring, sequentially add 14.3 parts of colorless dye microcapsules, 71.5 parts of color developer, 7 parts of polyvinyl alcohol, 3 parts of acrylic resin, 3 parts of styrene-acrylic emulsion and 1.2 parts of surfactant OBS. Once the raw materials are stirred evenly, add the next one;

[0048] 2) After all the addition is completed, adjust the viscosity of the obtained coating liquid with water until the viscosity measured by the 4 viscosity cup is 12 seconds;

[0049] 3) Filtrate with a wire-wound filter, and defoam statically for 7 hours under slow stirring until the bubbles are completely discharged.

[0050] Tu 4 Viscosity Cup is designed according to GB1723-79 GB1723-79 National Standard Paint Viscosity Measurement Method, and it is a widely used viscosity cup in this field. Under certain temperature conditions, measure the t...

Embodiment 2

[0068] The coating solution for forming a thermosensitive recording layer is obtained by the following preparation method:

[0069] 1) Under slow stirring, sequentially add 16.5 parts of colorless dye microcapsules, 66 parts of color developer, 8 parts of polyvinyl alcohol, 4 parts of acrylic resin, 4 parts of styrene-acrylic emulsion and 1.5 parts of surfactant OBS. Once the raw materials are stirred evenly, add the next one;

[0070] 2) After all the addition is complete, adjust the viscosity of the obtained coating liquid with water until the viscosity measured by the 4 viscosity cup is 13 seconds;

[0071] 3) Filtrate with a wire-wound filter, and defoam statically for 9 hours under slow stirring until the bubbles are completely discharged.

[0072] The leuco dye microcapsules are made of an oil phase and a water phase, the mass ratio of the oil phase and the water phase is 1:1.5, and the oil phase includes 2-phenylamino-3-methyl-6-di Butylaminofluorane, mineral spirits ...

Embodiment 3

[0088] The coating solution for forming a thermosensitive recording layer is obtained by the following preparation method:

[0089] 1) Under slow stirring, sequentially add 26 parts of colorless dye microcapsules, 52 parts of color developer, 10 parts of polyvinyl alcohol, 5 parts of acrylic resin, 5 parts of styrene-acrylic emulsion and 2 parts of surfactant OBS. Once the raw materials are stirred evenly, add the next one;

[0090] 2) After all the addition is completed, adjust the viscosity of the obtained coating liquid with water until the viscosity measured by the 4 viscosity cup is 14 seconds;

[0091] 3) Filtrate with a wire-wound filter, and defoam statically for 10 hours under slow stirring until the bubbles are completely discharged.

[0092] The leuco dye microcapsules are made of an oil phase and a water phase, the mass ratio of the oil phase and the water phase is 1:2.0, and the oil phase includes 2-phenylamino-3-methyl-6-di Butylaminofluorane, mineral spirits a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com